sustainability

100% recycled material - 100% quality

| Petra Rehmet

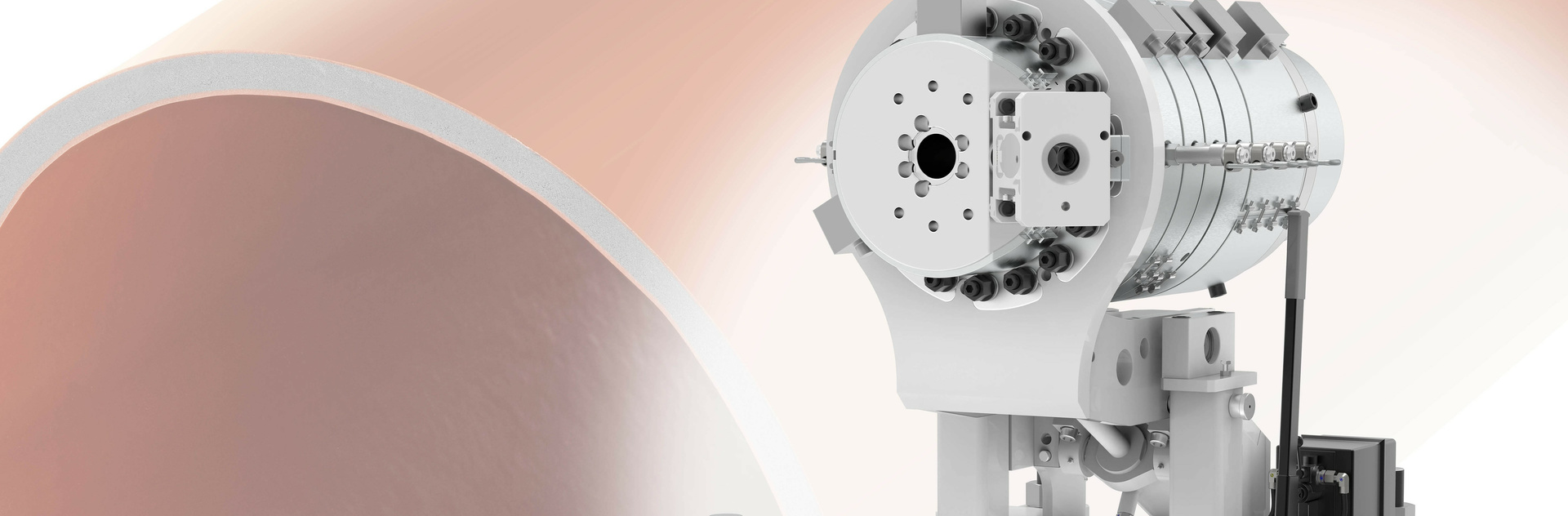

New 3-layer pipe head for PVC

Processing recycled materials economically and safely is no longer a promise for the future, but reality. With the new KM-3L RK 42-HP 3-layer pipe head, KraussMaffei Extrusion shows how sustainable PVC processing works today.

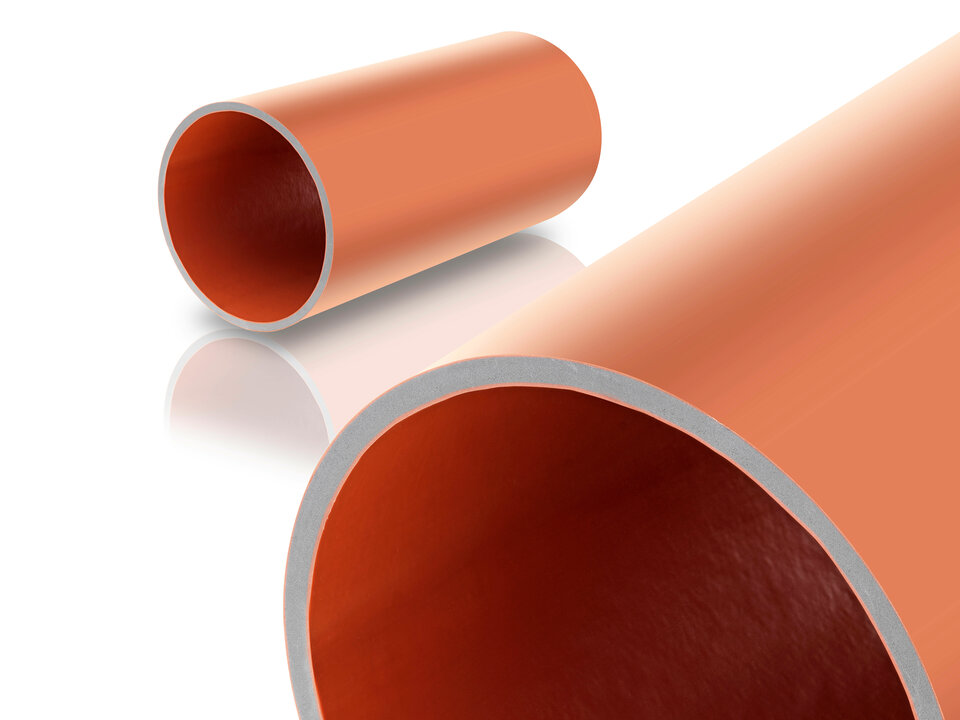

Whether in new construction areas or in the renovation of old pipe networks, PVC sewage pipes play a central role in infrastructure. And this is precisely where there is a growing need for sustainable solutions that conserve resources, function reliably, and are economical.

The new KM-3L RK 42-HP 3-layer pipe head delivers exactly that: it processes up to 100% recycled material in all three layers without compromising on quality, process stability, or surface finish.

Two years of development work for a real technological change

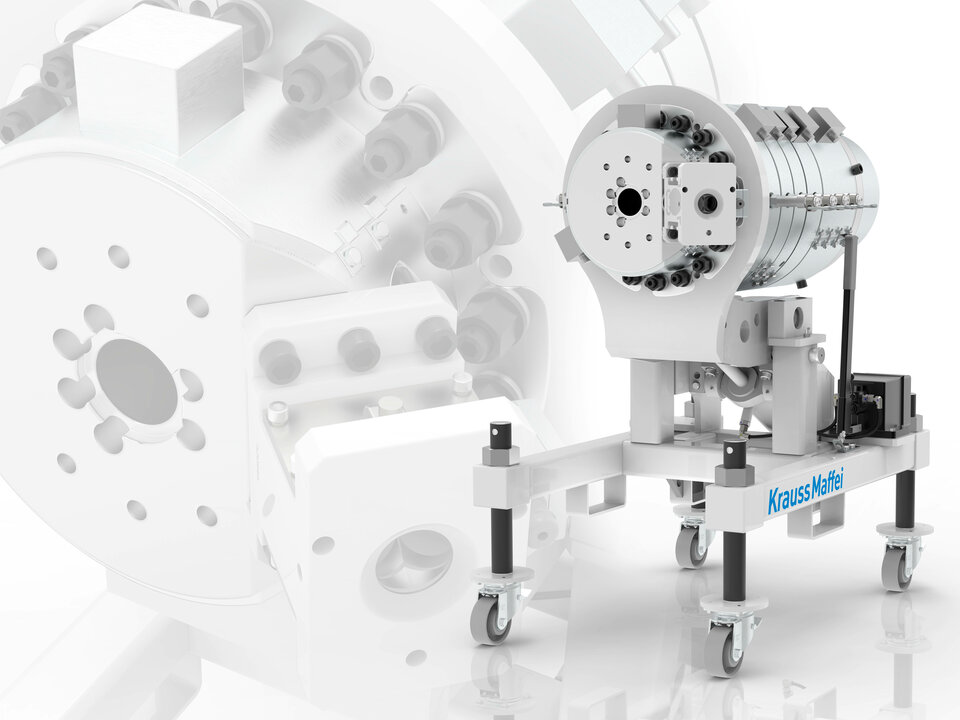

The new pipe head is not an update, but a completely newly developed system and is designed from the ground up for maximum flexibility, energy efficiency, and recyclate compatibility.

It was developed for pipe diameters from 110 to 250 mm and throughputs from 400 to 1,200 kg/h. This makes it ideal for industrial applications where high volumes and consistent quality are required.

With the new KM-3L RK 42-HP, we are presenting the most advanced 3-layer die for PVC applications. Our customers benefit from economical, sustainable, and outstanding quality pipe production.Klaus Lorius

Head of Sales Pipe & Profile KraussMaffei Extrusion

The heart of the system: patent-pending flow system

The key to success is a high-precision, symmetrical flow system that precisely controls the three layers. Particularly exciting: the solution for the core layer.

Here, an efficient 1-to-8 distribution ensures extremely short dwell times. This is ideal for the stable processing of recyclates that are prone to fluctuations. Whether foamed or compact, whether in-house recyclate or post-consumer waste: the quality remains constant.

The top layers are also designed for 100% recycled material. This is a future-proof advantage, as the pressure to replace virgin material is growing rapidly.

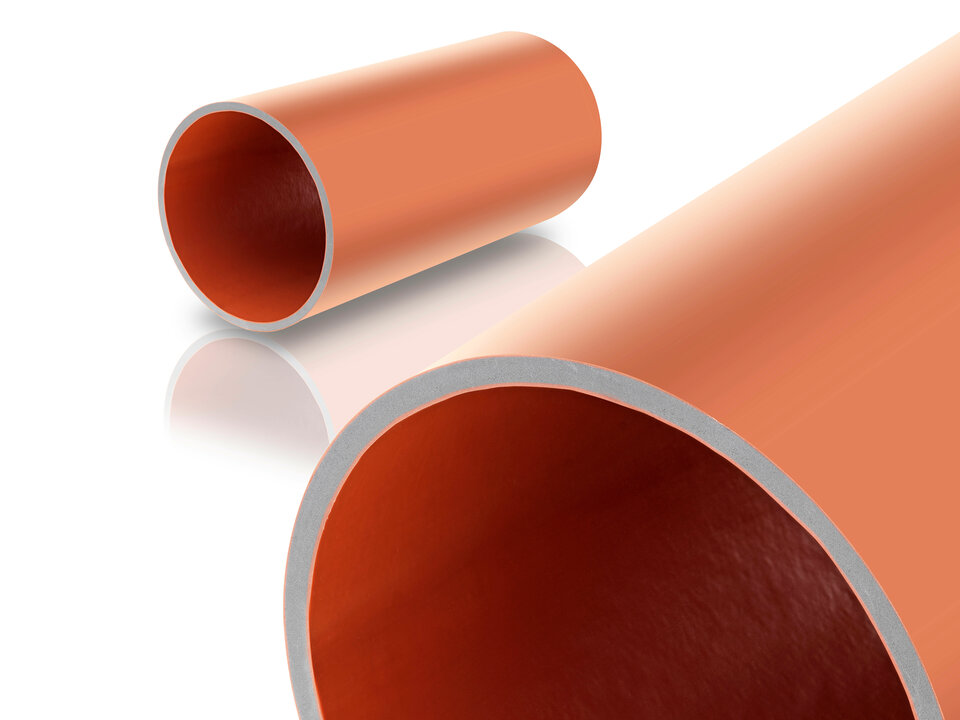

Efficient and sustainable: The new 3-layer PVC pipe head enables the safe and stable processing of up to 100% recycled material, even with highly variable material quality.

Sustainable savings – in materials and production

A major advantage is that the system allows for a particularly wide process window. This enables long production runs with minimal interruptions.

At the same time, material costs are significantly reduced because the recycled material used replaces expensive virgin material. Especially in a market where material costs often account for over 70% of operating costs, this is a real game changer.

No streaks, no compromises

The result is also visually impressive: spider lines - fine, irregular streaks on the inner wall of the pipe - are now virtually a thing of the past. The new flow system ensures an even, turbulence-free material flow and thus a perfect surface.

And last but not least, the pipe head does not require chrome plating or double compression. This reduces the environmental impact, simplifies cleaning, and reduces downtime during replacement.

Ready for use in modern piping systems: 3-layer PVC wastewater pipes made from up to 100 percent recycled material.

Conclusion: Performance meets sustainability

The new KM-3L RK 42-HP is much more than just a new tool – it is a real statement for sustainable PVC pipe production. Highest quality, full use of recycled material, lower operating costs and quick integration.

This makes it the ideal solution for anyone who wants to make their processes more economical and sustainable.

Experience the new 3-layer pipe head live at K 2025 in Düsseldorf (October 8–15) – at the KraussMaffei booth: Hall 15, C24