trendgineering

pioneer processControl from users for users

| Andreas Weseler

Premiere for design award-winning extruder control panel at the K show

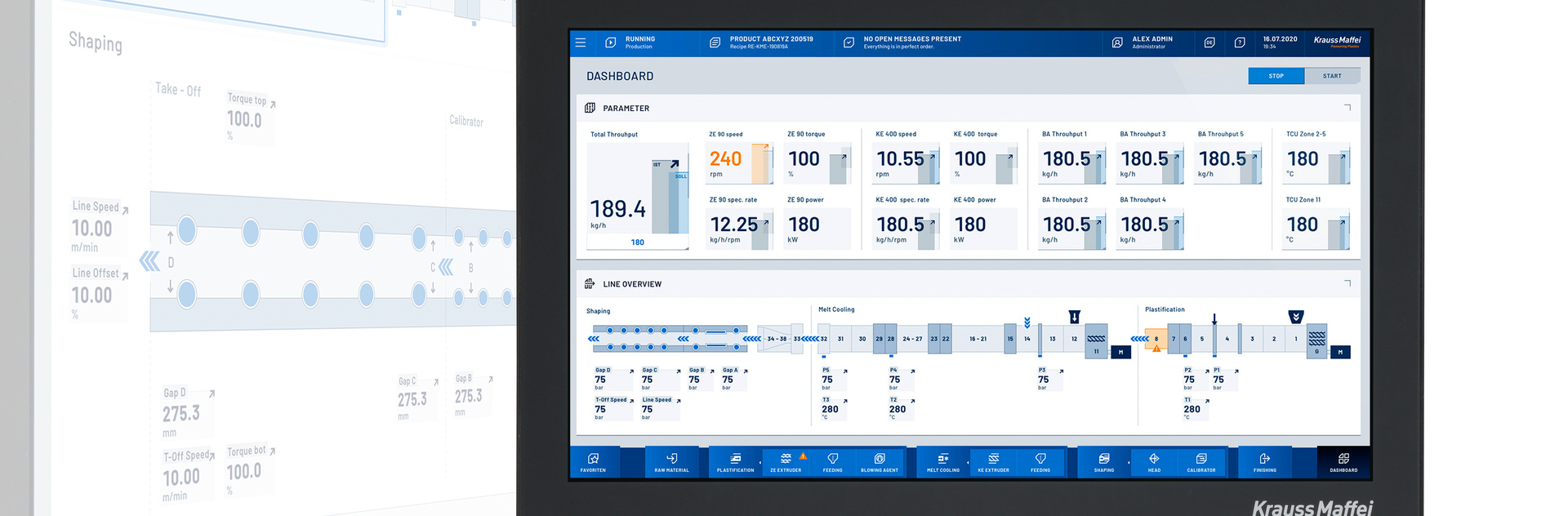

Guiding the operator safely through the entire production process is the most important task of the machine control system. The pioneer processControl was developed by users for users of extrusion lines. The user interface, which received the reddot Award 2021 and the iF Design Award 2022, will be premiered on the ZE 28 BluePower at the K show.

What does a user need to be able to operate a machine well? This question was at the beginning of the User Interface project. KraussMaffei asked customers from the tire, pipe and foam industries, consulted the SKZ and finally developed pioneer processControl with the company HMI Project GmbH, a specialist in human machine interface (HMI) design.

With the new user interface, we have created a clear and intuitive unit that ideally reflects the complexity of any plastics and rubber processing operation.René Jordan,

Wizards for higher efficiency

An important part of this is played by the so-called wizards (a core feature), which provide users with step-by-step instructions for specific workflows, such as starting up or shutting down the entire plant. As wizards should, they appear at the exact moment in the process when their information is needed, and users can additionally deposit their insights in the system for colleagues to benefit from. In this way, even a less experienced operator can take control of a complex extrusion process. Operator errors are reduced, resulting in less downtime and thus higher production efficiency.

Modern user interface for extrusion lines

At the K show, the ZE 28 BluePower will be part of the closed material loop presented, in which a colored PP recompound for high-quality applications is created from live injection-molded and shredded medical caps. Such complex extrusion processes, which use recyclates of varying specifications as input material to produce ready-to-use additivated and colored recompounds, are becoming more and more standard in the industry for sustainability reasons. The more demanding the process in terms of metering, coloring and degassing, the more data must be processed by the control system and displayed on the interface.

The visual design of the interface is self-explanatory, tidy and clear, following the motto "as much as necessary, as little as possible". Deviations from target values are indicated by appropriate visual feedback, so that early intervention is possible. The fact that the combination of graphic design and high user-friendliness has been well achieved is confirmed by the prestigious iF Design Award 2022 and reddot Award 2021 prizes for the pioneer processControl.

The new pioneer processControl increases production efficiency on the ZE 28 BluePower twin-screw extruder

The design could be implemented almost completely with the web-based HMI and SCADA toolbox WebIQ from Smart-HMI GmbH. Thanks to the web technology, the Human Machine Interface can be used hardware-independently and new applications can be implemented more easily on mobile devices. The modular HMI concept means that additional data suppliers, such as the ColorAdjust color measurement and control system also presented at the trade show, can be integrated into the control interface without having to adapt the operating concept.

The pioneer processControl therefore not only brings greater production efficiency and operating convenience in the present, but is also equipped for future developments. After all, the user is at the center of the entire development.