digitalization

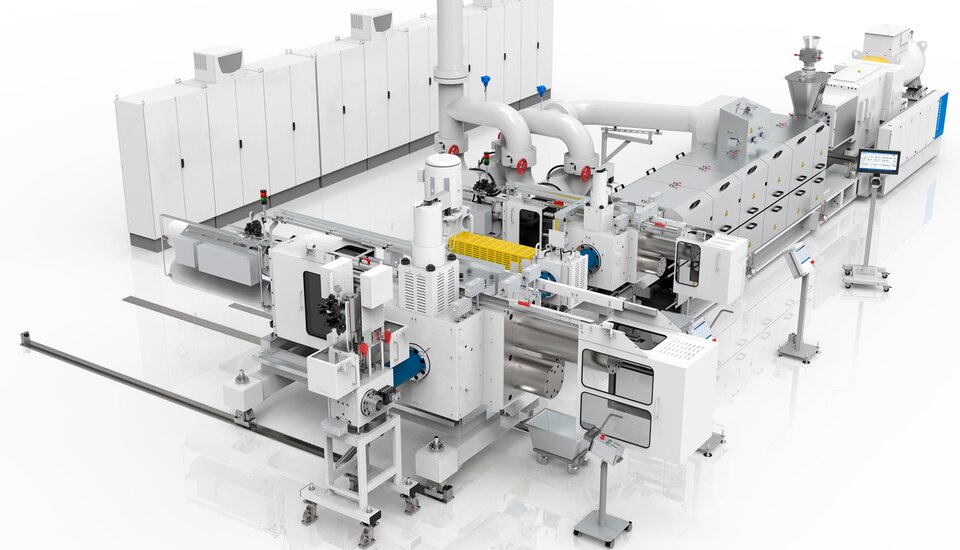

KraussMaffei: pioneer processControl

| Andreas Weseler

Increasing productivity in extrusion

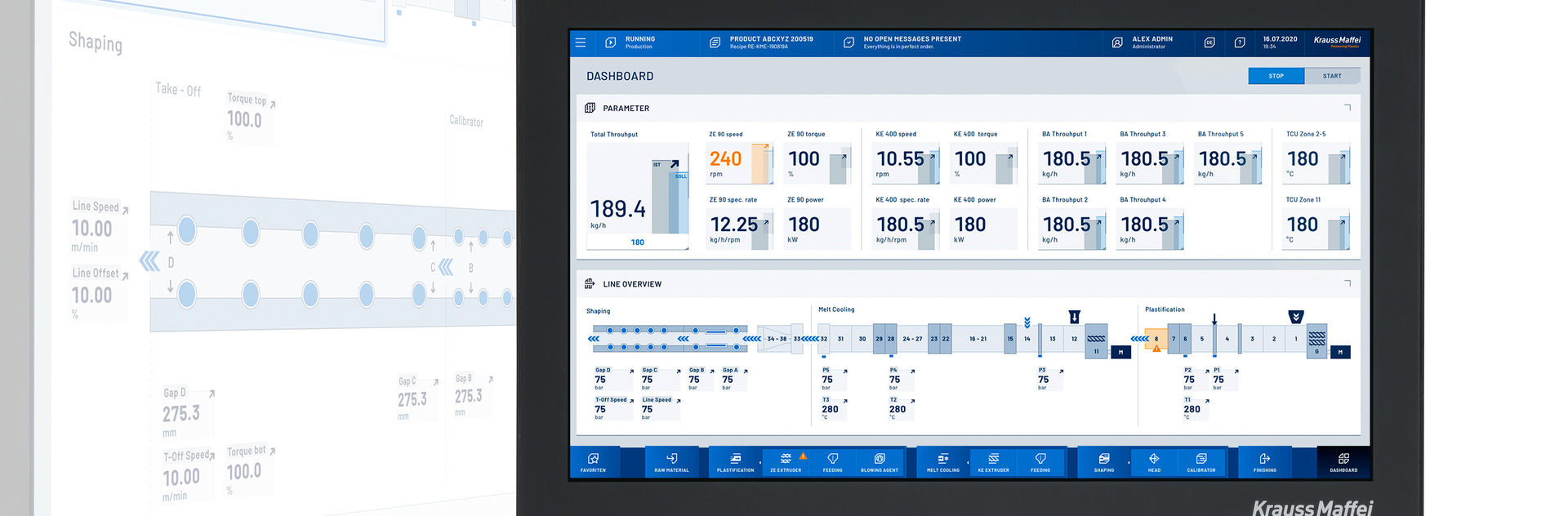

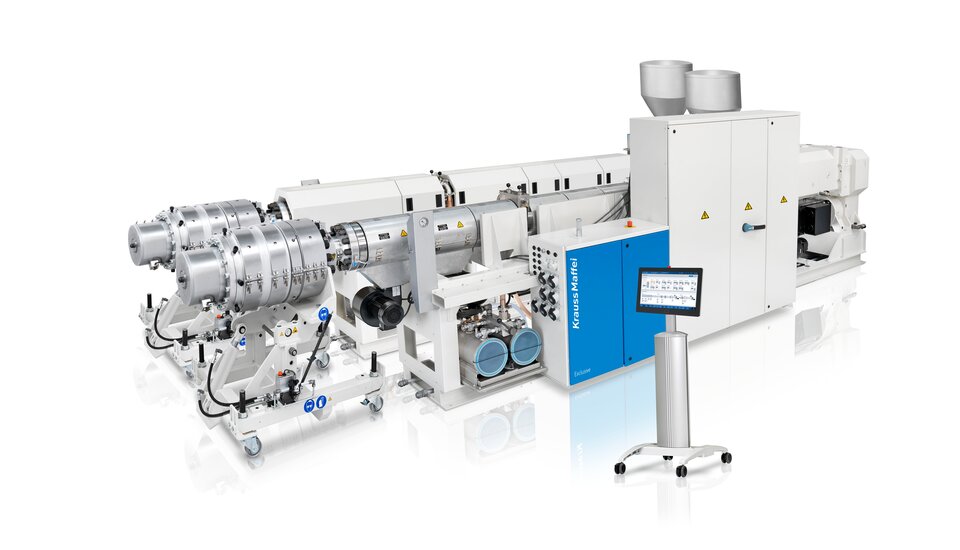

All indications automatically at the right moment: What makes life easier in road traffic also pays off when operating a production plant. The user-centered control system pioneer processControl guides even less experienced users step by step through the process and maintains constantly an overview. For example, batch trends can be compared from layer to layer. After foam extrusion, compounding and recycling lines, pioneer processControl is now also available for pipe plants.

pioneer processControl - User-friendly control for step-by-step process control and batch comparisons in tube plants.

When starting up an extruder, it is necessary to observe a certain sequence: selection of the recipe, preheating of the processing unit, starting the extruder and the metering unit, gradual ramping up of the conveying capacity and conditioning. Experienced professionals are already familiar with this procedure. For new employees or career changers, however, support is recommended in order to produce high-quality material as quickly as possible.

For this purpose, pioneer processControl will offer so-called wizards in the future, which support the operators during critical process steps. Here, the operator is guided through critical situations such as start-up, thus avoiding operating errors and production downtimes. The pioneer processControl control system is consistently designed from the user's perspective and offers not only a high level of safety but also intuitive ease of operation. Several design awards (including the coveted IF Design Award and the German Design Award 2023) honor the clear structure and clean look.

For new employees or career changers, Pioneer processControl will offer support in the form of so-called wizards in the future. These support operators in critical process steps in order to achieve high-quality material quickly.

User-friendly design and customization options

René Jordan (Teamlead Software Engineering at KraussMaffei) and his team specifically focused on icons and functions that are familiar in the context of operating other digital devices, for example the use of "swipe" motions. Where icons are not specific enough, they have additional text information. In addition, there is the possibility of some customization of the controls.

Configurable pages that can be customized by the operator.René Jordan

Teamlead Software Engineering KraussMaffei

Pioneer processControl - Simple step-by-step process control with comprehensive overview, now also available for pipe lines.

Parameters such as material throughput, speed and torque are not only indicated numerically, but can also be visualized in the form of bar charts. Both target and actual values, as well as the deviation between them, are immediately visible. The temporal behavior of the values is also represented by a direction arrow.

The visual feedback permanently provides valuable information. If, for example, the temperature in the plasticizing unit does not rise during heating, a closer examination is required.

Overview and functionality: The versatility of the pioneer processControl screen display

In standard operation of pioneer processControl, a quick glance at the screen reveals all the essentials: The top line shows the current status, the manufactured product, plant messages and the logged-in user.

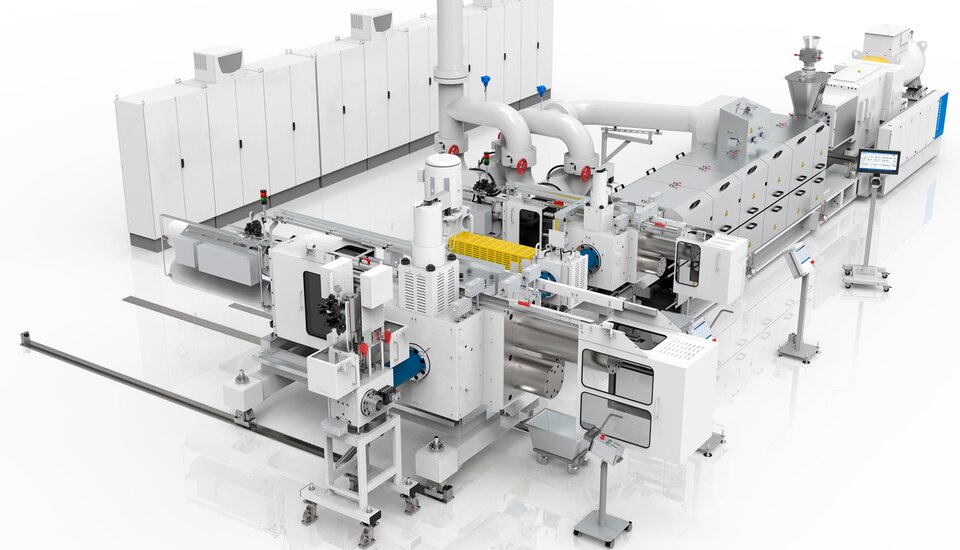

In the center section of the extruder, the process section including its various zones for plasticizing, cooling and shaping is shown schematically. There is the possibility to dive into each zone in more detail for further information. The representation of processes such as compounding, foaming, film and pipe production looks very different here - as in reality.

This was also taken into account in the implementation of the HMI. At the bottom of the monitor, a quick navigation facilitates direct access to frequently used plant components and parameters. Under the "Extruder" area, not only can current data on screw speed and the like be displayed, but also the status of the extruder and the development of the most important values over time can be viewed in a trend curve.

Pioneer processControl with trend system, which provides an effective way to compare different asset values.

Pioneer processControll offers a newly developed trend system with which the various plant values can be effectively compared. The operator is supported here by features such as handles, comparison function and trend comment function. The comments allow the notes from operators and experts to be recorded in the system and are also available in the long term thanks to the exportability of the values.

Intuitive operation and flexibility: The functions of pioneer processControl at a glance

With the "burger menu" placed in the upper left corner, the user can use the entire three hierarchy levels to go in depth step by step, and two levels can always be shown at the same time. The expert settings require in-depth knowledge and are aimed at users with the appropriate qualifications and clearance in the system. There are five access levels in total, the two highest for maintenance and administration. Users log in using their name and password, and it is also planned to use RFID.

The pioneer processControl status concept relies on electronic components from Siemens, which makes the control system even more compatible and familiar to many customers. The availability of spare parts is improved because they are easily accessible. External plant visualizations can be connected directly via HTML5 interface or VNC. On the other hand, the visualization of the pioneer processControl can also be easily integrated into other systems. Communication to other control and customer systems takes place via Profinet or OPC UA.

pioneer processControl effortlessly integrates upstream and downstream equipment. Communication takes place via Profinet or OPC UA.

The display of pioneer processControl and process monitoring are also possible on mobile devices, but for safety reasons the machine can only be controlled via the permanently attached touch panel. Remote access takes place with remoteAccess, a product of the digital division of KraussMaffei (Digital Service Solutions) via a secure VPN tunnel.

These features give the customer full control over all processes. With its consistently user-centric approach, Pioneer ProcessControl combines modern process control and operation with convenience and efficiency.