insights

185 years of KraussMaffei

| Gerhard Konrad

We celebrate 185 years of pioneering spirit

This year, KraussMaffei is celebrating 185 years as a company. A 185-year company history is something special, not only in the plastics industry. Rarely do companies achieve a similarly long history.

In order to maintain the continuity of the company's success despite all the disruptive events in politics, technology, culture and the economy, one thing above all is needed: a pioneering spirit at the top of the company and among the employees, who constantly reinvent and develop their company with new ideas for products and markets.

Technical developments must be advanced or adapted, new markets opened up and obsolete products replaced by contemporary ones. In this way, a company of global standing can emerge from small beginnings and successfully satisfy customers over many decades.

1838: The beginnings of locomotive construction

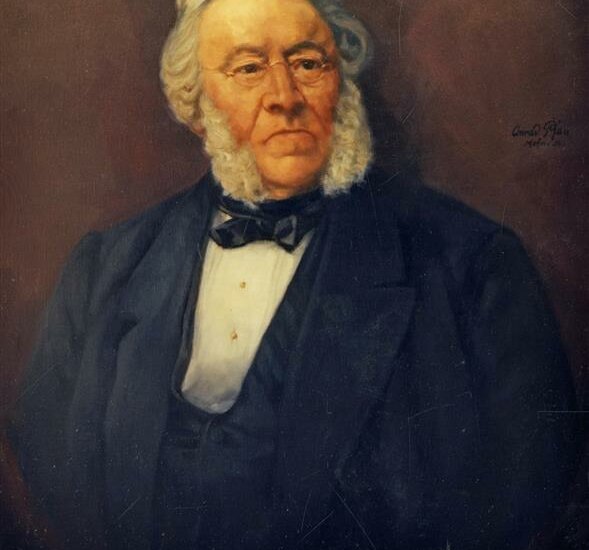

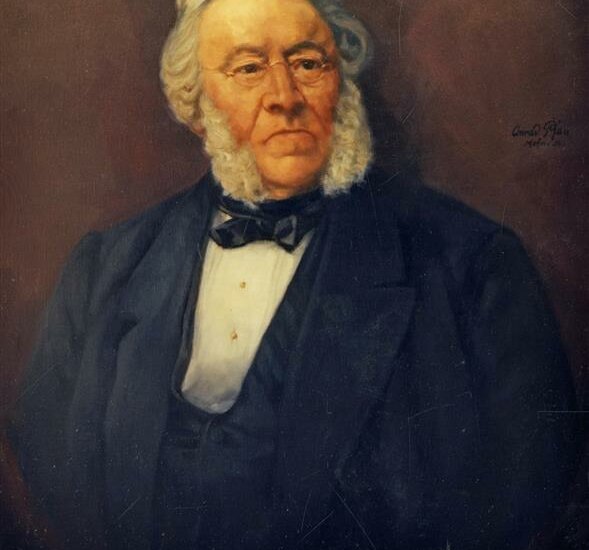

Joseph Anton von Maffei

When Joseph Anton von Maffei founded his Hirschau ironworks in Munich in 1838, he wanted above all to profit from the booming expansion of railroad traffic. In 1841, Maffei delivered the first locomotive, "Der Münchner". The maximum speed of this locomotive was 30 km/h. Soon, however, the company was also active in other fields, such as the construction of stationary steam engines, the building of steamships for Danube navigation and navigation on the Bavarian lakes. In addition, there were steam road rollers and traction engines for road construction and the manufacture of turbines. Maffei was also involved in the electrification of Bavaria at the end of the 19th and beginning of the 20th century.

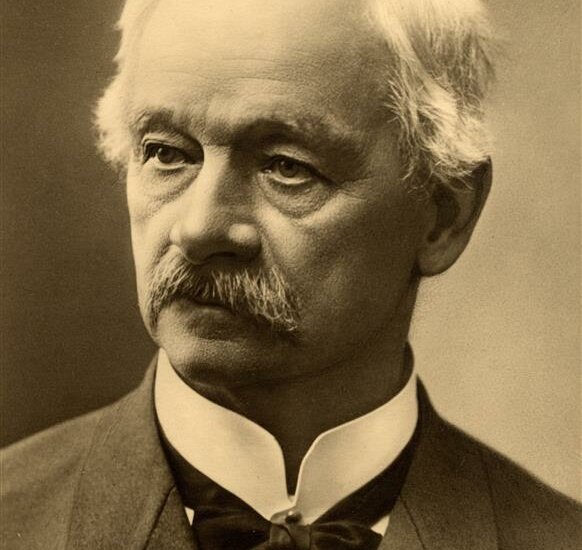

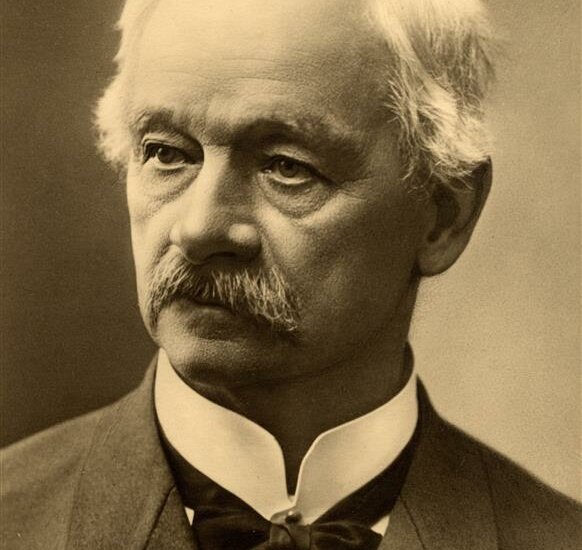

Georg Krauß (1826-1906)

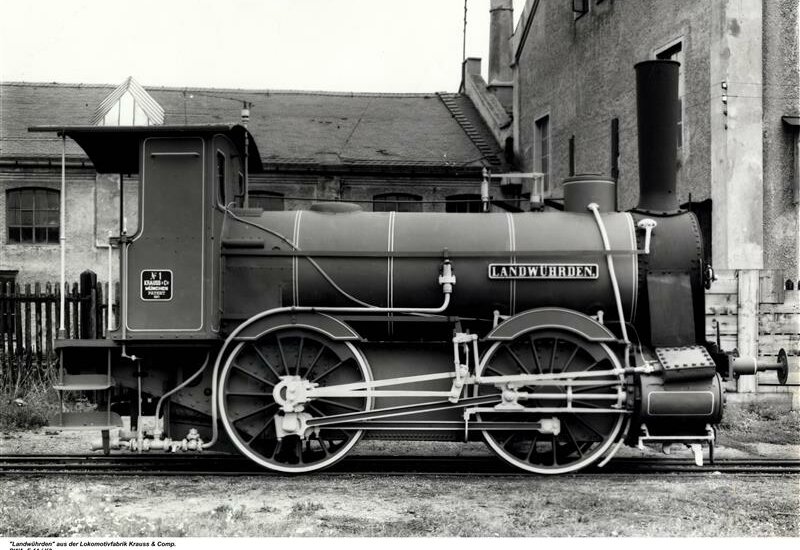

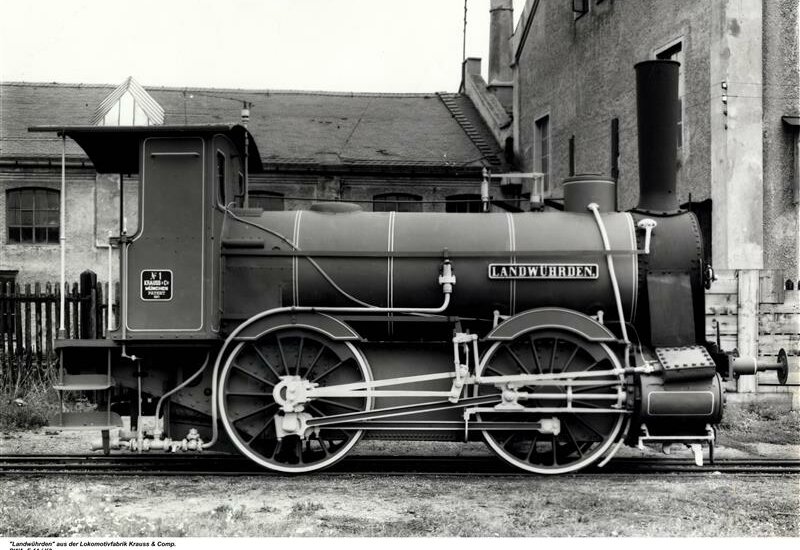

The second eponymous company, Krauss & Comp. AG, founded in 1866 by Georg Krauß, also specialized in locomotive construction. The company was particularly known for its narrow-gauge trains for private railroads, industrial and mining operations. With their locomotives, Krauss and Maffei played a major role in the expansion of railroad traffic in Europe. Boom phases, wartime and the crises of the 1920s equally shaped the development of J. A. Maffei AG and Lokomotivfabrik Krauss & Cie. In 1930, when the world economic crisis was approaching its peak, Maffei AG also ran into economic difficulties.

1931: Merger in the crisis

In January 1931, the companies Krauss & Comp. and J.A. Maffei AG merged to form "Lokomotivfabrik Krauss & Comp. - J.A. Maffei A.-G München". But as early as 1940, the shorter name Krauss-Maffei AG was used. In 1933, construction of the plant in Allach began. The administration building in Allach was erected in 1936/37. The portfolio had already been expanded since 1925 to include trucks and later tractors. Even during the years of Nazi rule and the Second World War, this product range essentially remained unchanged.

The great transformation

The transformation into one of Germany's most important armaments groups and later into the market leader for plastics machinery with a purely civilian portfolio did not take place until the period after the Second World War. This phase was anything but straightforward. Particularly in the plastics processing segment, the pioneering spirit that has prevailed at KraussMaffei prevails.

1957 Injection molding machines expand the portfolio

Krauss-Maffei injection molding technology presented at Hannover Messe 1959

The first injection molding machines were built in Munich-Allach in 1957. Almost 30 years later, plastics machinery production was an independent GmbH (limited liability company) and technologically at the forefront of the world. Every fifth machine for the production of CDs came from KraussMaffei in 1986. Already 1987, microprocessor control was part of the standard equipment of the machines. Legendary is the Alpha 1, a multifunctional laboratory machine with a clamping force of 5,000 tons, which was ordered by General Electric. It weighed around 1,000 tons.

KraussMaffei's connection to the automotive industry has long been particularly close. It is no coincidence that the 5,000th injection molding machine of the B series went to an automotive supplier in Asia in the summer of 1994.

Plant for the production of bumpers

Cutting-edge technology for plastics processing

With the introduction of the MC series in the two-platen clamping concept, injection molding machines could be built about a third shorter from 1995. In the same year, the first twin-screw extruder for the production of PVC profiles also went into operation. With an output of 1,000 kilograms per hour, it produced two profiles simultaneously.

Growth and diversification

Plastics machinery became increasingly important for the company as a whole. In 1995, sales in the division exceeded one billion DM for the first time, and by 1997 half of the Group's sales came from this segment. A number of corporate acquisitions contributed to this. Netstal Maschinen AG in Näfels (Switzerland) has been part of the Group since 1991. Specializing in PET preforms on high-precision multi-cavity molds, it still makes an important contribution to the company's success. Berstorff Maschinenbau, specializing in equipment for rubber processing, was added as a further mainstay in 1994.

Restructuring in the 1990s

At the end of the 1990s, the ownership structure was restructured, resulting in the KraussMaffei Group as a company for the three divisions of Injection Molding, Reaction Process Machinery and Extrusion Technology and Rubber Processing divisions respectively.

2016: KraussMaffei Group becomes part of ChemChina

Since April 2016, KraussMaffei has been part of the ChemChina Group, which has now been merged into Sinochem, and is continuing its path into the future strengthened by this backing. Digitalization in plastics processing in particular has been consequently driven forward since then.

Into the future with new plants

KraussMaffei had been based in Munich-Allach for around 90 years. We recently left this historic site with great regret but for good reasons and moved to a new, state-of-the-art plant in Parsdorf. We have also commissioned new sites in Laatzen and in Einbeck, as well as in Jiaxing. At all of these locations we now have what are probably the most modern production conditions in the entire industry. They make the company fit for a promising future.