Insights

1986: Backfoaming becomes part of the program

| Petra Rehmet

Instrument panels, carpets and armrests

In the mid-1980s, the efficient backfoaming of instrument panels and carpets became the focus for reaction process machinery for car interior applications.

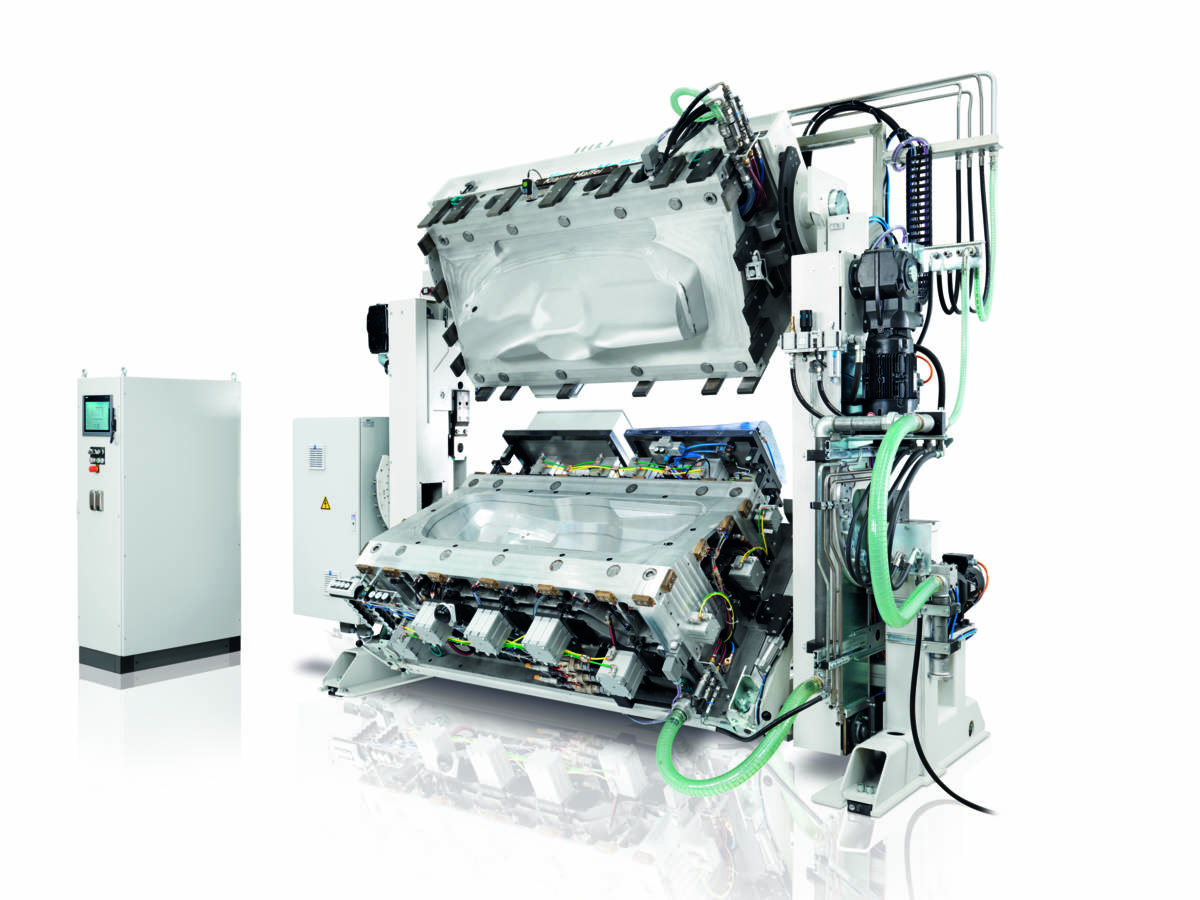

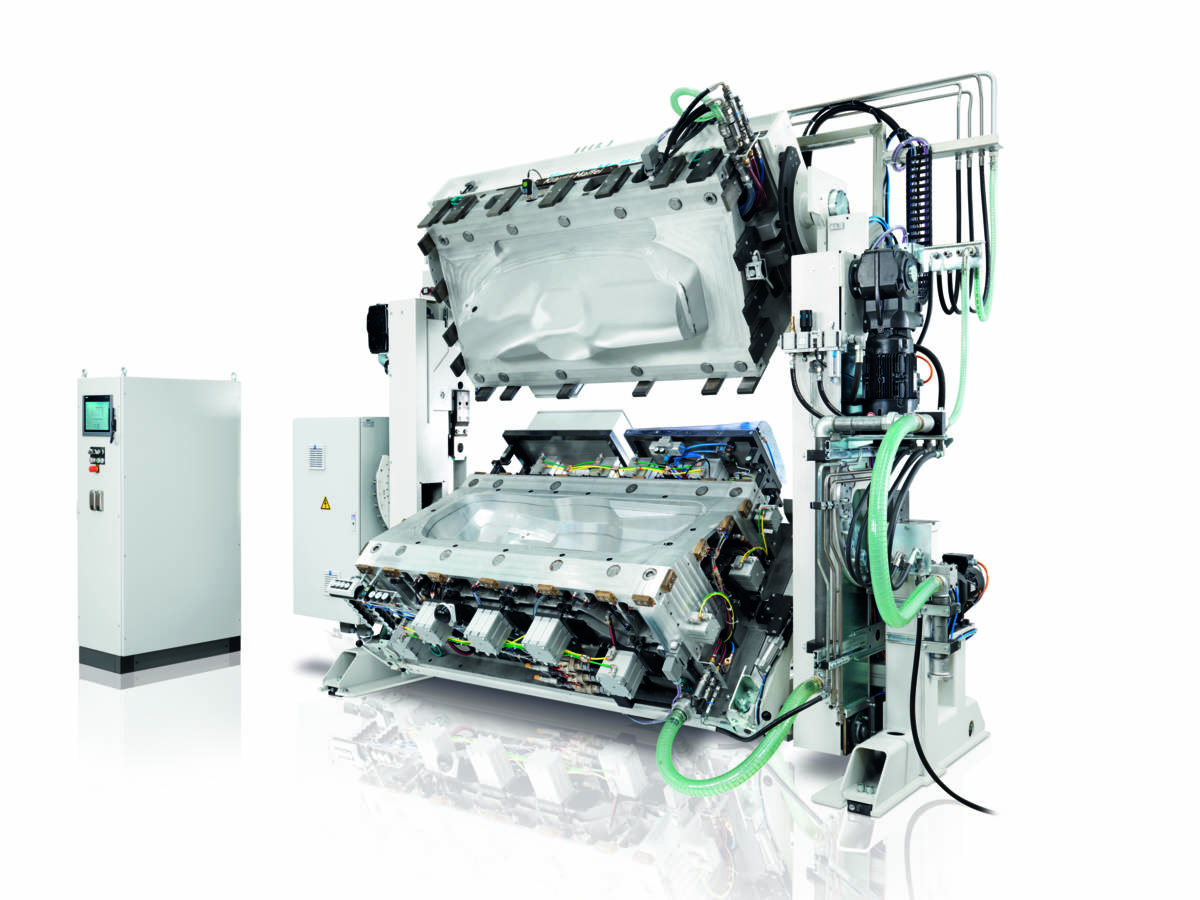

As the largest customer, the automotive industry was always the pacemaker for the further development of plastics machines and research into new materials. Because for the manufacture of light components such as those required primarily for the automotive industry, nothing is as suitable as plastic. And so, in the mid-1980s, the backfoaming of large-format parts became the focus of reaction process machinery at KraussMaffei. The "Open-Book" automobile carpet mold carrier, which was presented in 1986, gave a boost to the use of this technology. Three years later, the further development of the process was presented: Units for the backfoaming of vehicle instrument panels and armrests. In 2008, KraussMaffei introduced its first all-electric mold carrier for instrument panel backfoaming.

The process is still in use today. All machine movements are fully electric. This accelerates and ensures precision for all opening and closing movements in production, and, on account of simultaneous travel and swivel motions, results in shorter cycle times. Already for 50 years, KraussMaffei Reaction Process Machinery has been driving success in the sector.