sustainability

A successful Partnership

| Andreas Weseler

KraussMaffei Extrusion and the IKK - Institute of Plastics and Circular Economy at Leibniz University Hannover (LUH)

A successful collaboration with a major goal: sustainable progress through technological synergies. To this end, a state-of-the-art recycling plant has now been put into operation.

Shaping the technologies of tomorrow requires a close connection and continuous knowledge transfer between universities and businesses. Collaboration and knowledge exchange between educational institutions and industry partners are of paramount importance. Ensuring state-of-the-art technology resources for students and researchers is increasingly essential.

A notable example of such a partnership is the successful collaboration between KraussMaffei Extrusion and the IKK - Institute of Plastics and Circular Economy LUH.

The collaboration aims to advance the development of plastics and circular technologies. By combining the profound expertise of IKK with the technical prowess of KraussMaffei Extrusion, innovative approaches are created to address current and future challenges in the field of high-quality plastic recycling,Prof. Dr.-Ing. Hans-Josef Endres

Director of the IKK

Innovative Concept: Closed-Loop Recycling for Higher Product Quality

A central concept of this project is "Closed-loop Recycling", where recycled plastics are reused in the industry where they originally came from after consumer use. The goal is to enhance product quality through high-grade purity and minimal input contamination by innovative recycling processes in combination with inline control of output-quality.

The partnership with IKK at LUH enables students and researchers to work with the latest KraussMaffei Extrusion technologies from the outset. This collaboration not only enhances education but also contributes to the development of innovative solutions that advance both industry and society.Xiaojun Cui

Managing Director KraussMaffei Extrusion

Sustainable Progress through Technological Synergy: State-of-the-Art Recycling Plant in Operation

The shared vision of KraussMaffei Extrusion and IKK is to advance technological progress in plastic recycling through research, education and practical application. This partnership strengthens the innovation landscape in Germany and lays the foundation for sustainable and forward-looking technology development.

The recently commissioned Edelweiss Recycling Plant, consisting of two ZE 28 BluePower extruders, is ideally suited for the economical recycling and compounding of plastic waste.

The ZE Blue Power twin-screw extruders used boast a large volume and high torque, resulting in maximum throughput performance with high quality. The plant aims to conduct essential research work by not only processing low-quality recycling streams but also those that have received little attention so far.

Furthermore, the plant offers the capability to process post-consumer waste, representing another step toward a sustainable circular economy.

This expansion enables the inclusion of plastic waste from consumer sources in the recycling process and reintroducing it into the circular economy.

Doctoral students supported by KraussMaffei Extrusion are actively involved in the plant, engaged in measuring, modifying, and validating various recycling processes.

The partnership between KraussMaffei Extrusion and IKK contributes to driving innovation in plastics processing and creating sustainable solutions for the future.

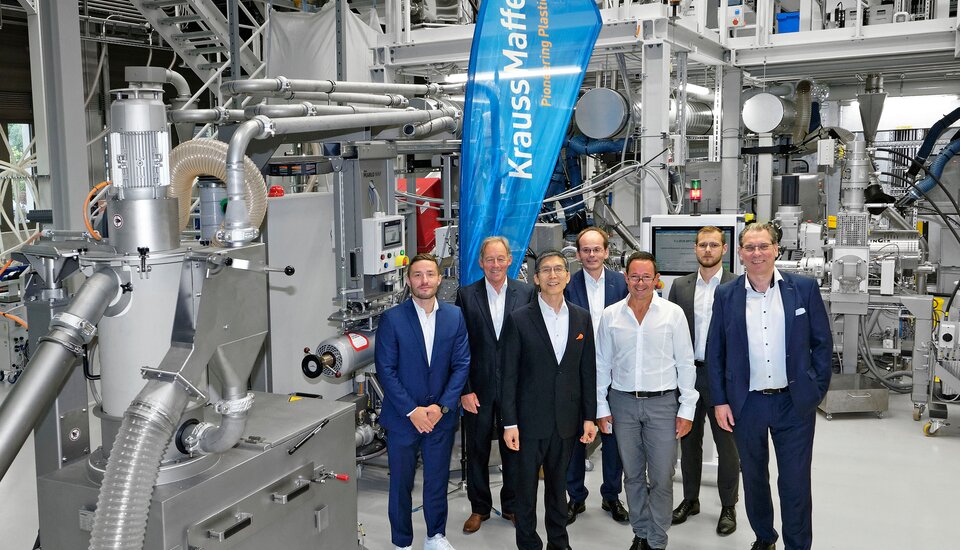

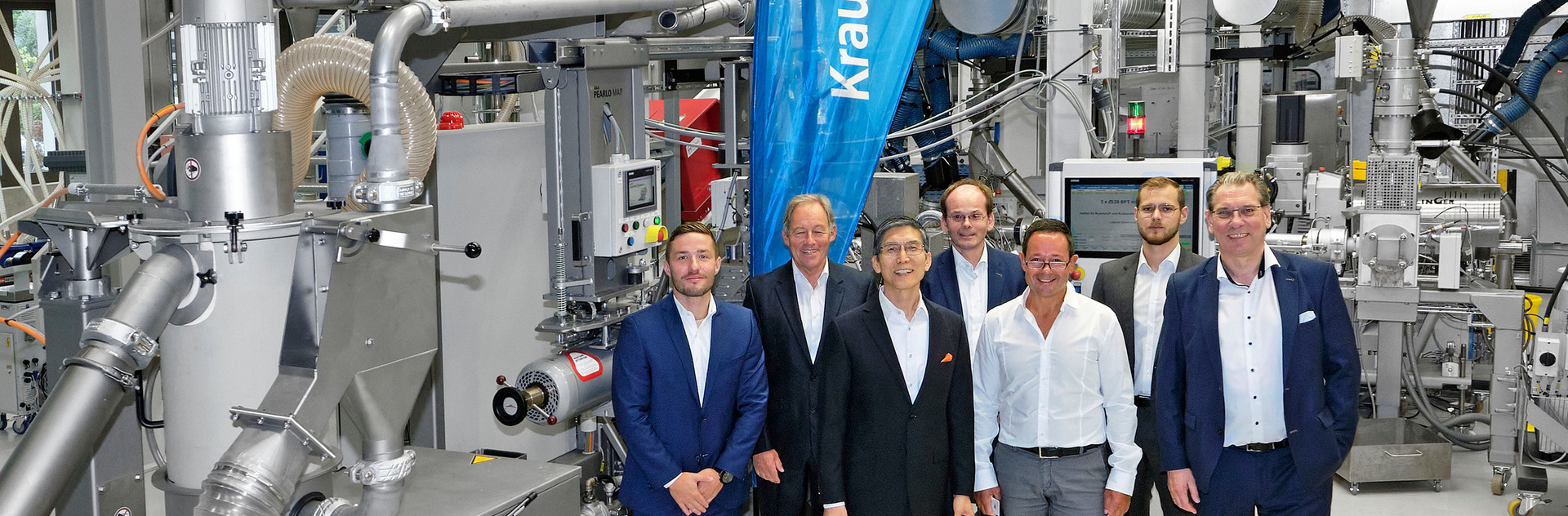

Partners in trusted mutual collaboration (f. l.): Felix Mehrens (PhD Student at the IKK), Jörg Hasse (Expert Sales, Compounding Recycling at KraussMaffei Extrusion), Xiaojun Cui (Managing Director bei KraussMaffei Extrusion), Gerhard Scheel (Leiter Entwicklung at KraussMaffei Extrusion), Prof. Dr.-Ing. Hans-Josef Endres (Director of the IKK - Institute of Plastics and Circular Economy), David Rapp (Teamlead Process Technology Compounding/Recycling), Ralf J. Dahl (Director Sales Extrusion ati KraussMaffei Extrusion)