Trendgineering

All-rounder for packaging

| Petra Rehmet

New GX with 11,000 kN clamping force

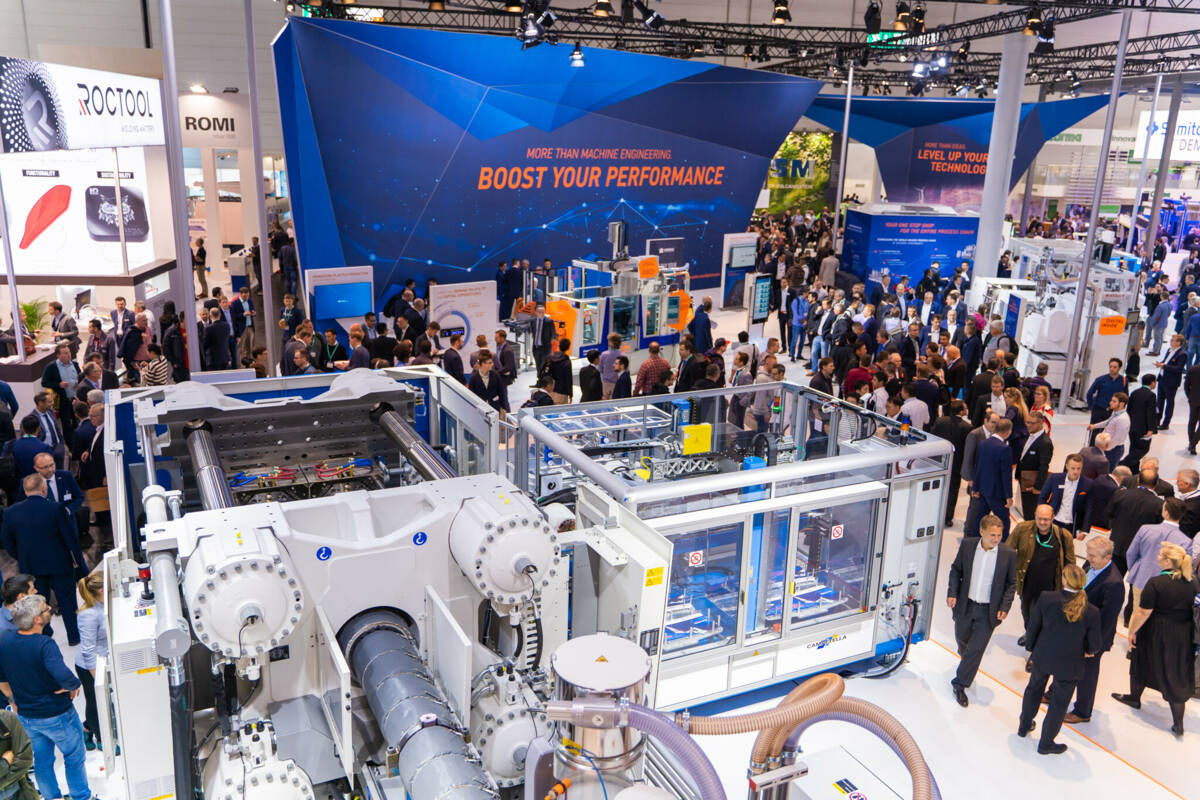

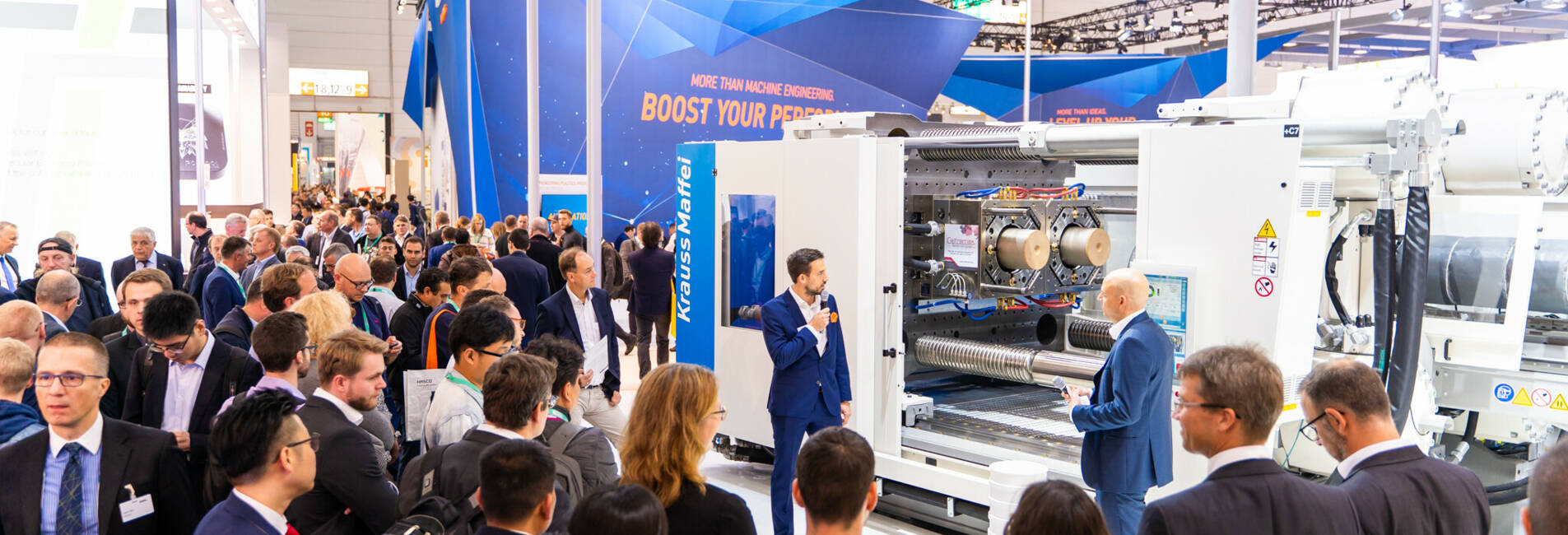

KraussMaffei has expanded its successful GX series and presented the new GX 1100 at the K 2019 trade show in Düsseldorf. In this interview, Product and Technology Manager Bastian Eberle explains what makes the new machine so special.

ahead

The GX is a classic midrange machine. Which industries and applications is it most suitable for?

Bastian Eberle

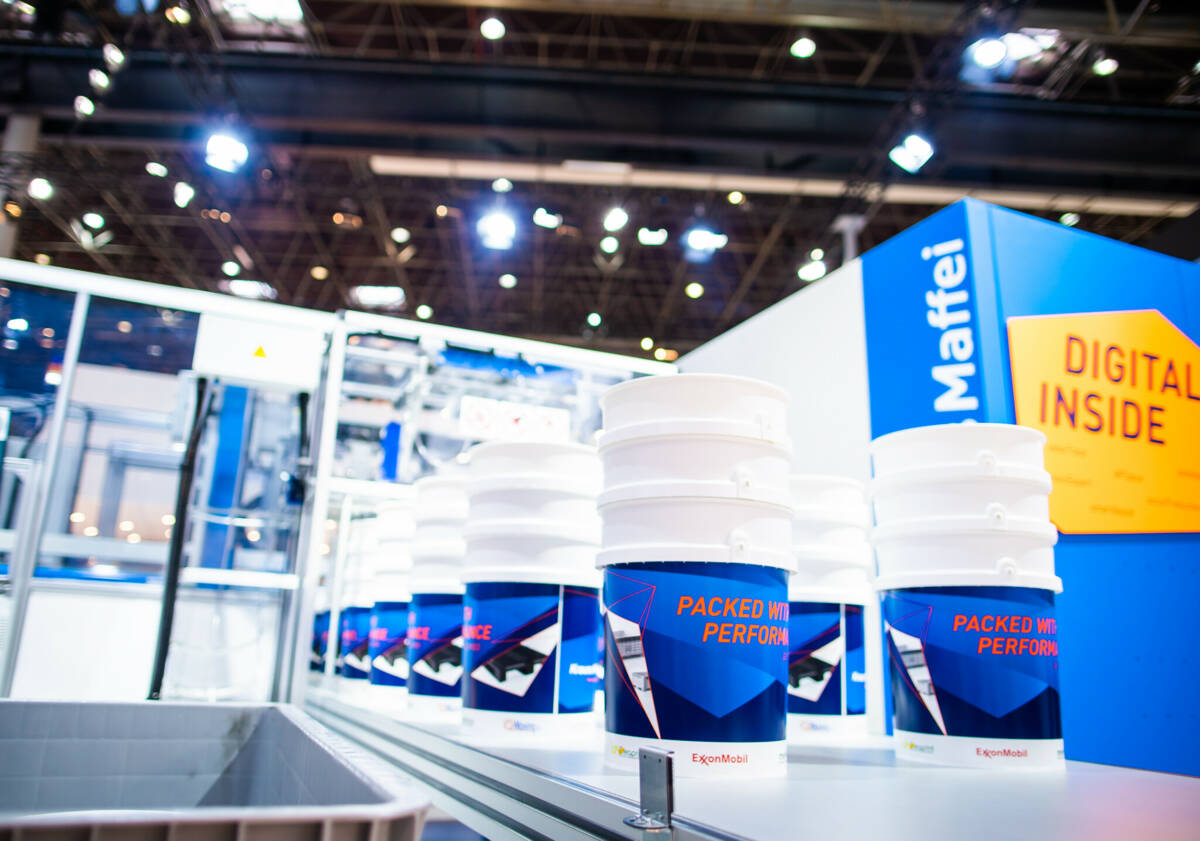

The great thing about the GX is its flexibility and the many different equipment options it offers. As a result, everything from bumper elements to small caps in high-cavity molds can be manufactured. At the K trade show, we used 20-liter buckets to demonstrate that the GX 1100 is also perfectly capable of handling bulky packaging items.

ahead

What was so special about this application?

Bastian Eberle

Decorating during the in-mold labeling process. Units of this size are usually either screen-printed or provided with an adhesive label. However, we were able to integrate these process steps, which otherwise take place downstream, into the injection molding cycle of the bucket itself. The IML label was made of polypropylene, the same as the bucket, in order to facilitate subsequent recycling.

"The great thing about the GX is its flexibility and the multiple equipment options it offers."Bastian Eberle, Product and Technolgy Manager KraussMaffei

ahead

Was the production process very time-consuming?

Bastian Eberle

No. In fact, thanks to the speed option for particularly fast clamping movements and the HPS barrier screw, we achieved a cycle time of less than 14 seconds despite the large opening stroke and the shot weight of 1500 grams. That corresponds to an output of 2.5 to 3 million buckets per year. We are seeing a growing demand for these large containers, so the GX 1100 puts us in a strong position to cater for this requirement.

ahead

Is the "big" GX different from its smaller counterparts, technically speaking?

Bastian Eberle

We've adopted proven property patterns like GearX (very fast locking device) and GuideX (power-absorbing guide shoe), while the clamping unit has of course been adapted to the larger dimensions of platens and molds. The speed configuration mentioned is also aimed at producing bulky articles. Also, for the first time, we used an HPS barrier screw for polyolefins, which was previously reserved for the large MX machine series. This barrier screw allows for particularly fast melting and high shot weights.

ahead

The "Smart Operation" digital solution was previously only available on NETSTAL machines, is that correct?

Bastian Eberle

Yes, we demonstrated "Smart Operation" on a KraussMaffei machine at the K trade show for the first time. This is where we can draw on our shared expertise. The term "smart operation" refers to the starting up and shutting down of machines using preconfigured processes. It means that setup staff can be trained much faster: they can control the entire process at the touch of a button. Operation is free of errors, thus preventing damage to the mold and machine.