sustainability

Button in the ear

| Petra Rehmet

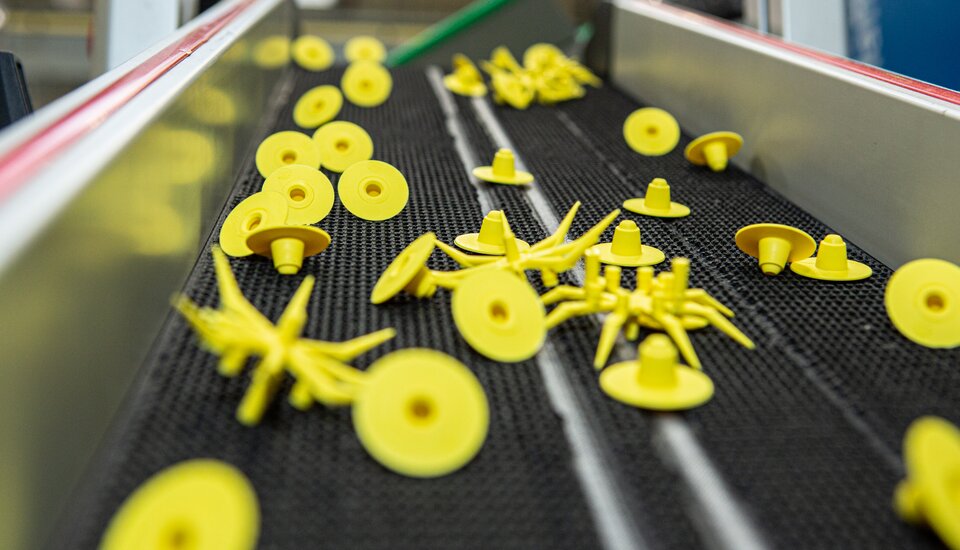

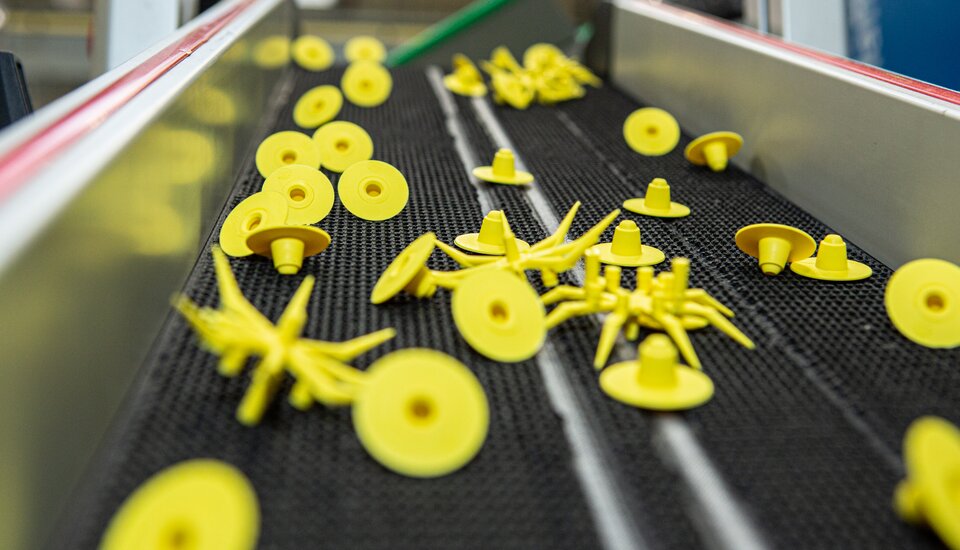

The new precisionMolding produces TPU ear tags for livestock

Farmers and livestock breeders around the world rely on Datamars' Livestock Identification solutions. They not only improve animal welfare, but also ensure comprehensive traceability in the food chain. At the Nitra site in Slovakia, an all-electric precisionMolding injection molding machine has been producing TPU ear tags for cattle, sheep and other livestock since 2023.

Datamars, headquartered in Lamone, Switzerland, offers a wide range of solutions for the identification of livestock. One of the main aspects is the electronic animal identification (E-ID).

This involves equipping animals with individual electronic identifiers, which are implemented using ear tags or RFID (Radio-Frequency Identification). These technologies enable precise identification and traceability of the animals, for example farmers can efficiently track health data, breeding histories and other information.

The traceability of livestock is in turn crucial for food quality assurance. By fully documenting the animal life cycle, from birth to slaughter, farmers can better control the entire supply chain. Thus, consumers receive safer and higher quality products.

In search of an affordable yet high-quality machine

Datamars has production sites worldwide and an extensive dealer and distribution network with an annual production volume between 200 and 220 million parts. The Nitra site in Slovakia focuses primarily on the production and distribution of Datamars products in Europe and Africa.

The portfolio and delivery volumes are correspondingly large. It is therefore important to act and produce quickly and flexibly. The first contact with KraussMaffei Sucany was made at the end of 2022. Since that date, the new precisionMolding has been developed here for the European market.

The high quality at best price has deeply convinced us.Stefano Mancuso

Plant Manager Datamars Slovakia

At that time, Datamars was looking for a new all-electric injection molding machine that would be affordable but also meet the high-quality requirements. "We looked at and tested various suppliers. We then decided on the new precisionMolding from KraussMaffei. Above all, the high quality convinced us, for example the better cycle times, the high precision and the better repeatability", explains Stefano Mancuso, Plant Manager Datamars Slovakia.

Appreciate the trustful cooperation (from left to right): Stefano Mancuso (Plant Manager Datamars Slovakia) and Martin Stepanek (CEO KraussMaffei Technologies Sucany) in front of the new precisionMolding 160-540.

At the beginning of 2023, the precisionMolding 160-540 with a clamping force of 1600 kN was delivered to Nitra - still a prototype at that time. Over the following six months of the test phase, the machine was further optimized.

"The cooperation with and support from the KraussMaffei team during this time was excellent. Although it was a prototype, the machine was immediately integrated into production. We’ve been very satisfied with it", says Stefano Mancuso, praising the collaboration.

Perfect plug-and-play solution - also for TPU

In addition to the fast delivery times and installation, the site manager particularly appreciates the ease of operation and maintenance of the precisionMolding. This makes production easier and increases efficiency.

The production runs 24/7, so the machine has to be robust and reliable. "Thanks to the short lead times, KraussMaffei always ensures that I can meet my production deadlines without delays", says Stefano Mancuso.

Easy and intuitive operation: the MC P1 control of the new precisionMolding

The precisionMolding produces ear tags for cattle, sheep and goats from TPU (thermoplastic polyurethane). TPU is a versatile material - it is flexible, elastic, abrasion-resistant and weatherproof and thus ideal to be used as ear tags for livestock.

But it requires a few special features during processing.

A look inside the mold: Processing TPU requires a special degree of precision. This is already covered by the standard version of the precisionMolding tool.

For example, TPU generally requires higher processing temperatures compared to other thermoplastics. This may require special injection molding machines and tools to ensure optimal processing.

TPU can also absorb moisture from the environment, which can lead to quality problems during the injection molding process. The precisionMolding meets these special requirements perfectly as standard, without having to resort to additional features.

This in turn speaks for the high quality of the machine despite its lower price.

Ideal for outdoor use: The TPU ear tags are particularly flexible, abrasion-resistant and weatherproof

For a sustainable and responsible farm future

Global agriculture will certainly become even more sustainable and responsible in the future, especially in the area of livestock farming. Datamars, as a pioneer in the field of livestock identification solutions, will accompany this change.

One step will be to replace old machines in production with new ones. And thanks to the good experience with precisionMolding at the Nitra site, further KraussMaffei machines from this series are a good option - thanks to outstanding quality and yet good price.

Modern sustainable agriculture tracks its livestock - Datamars ear tags are produced on the new precisionMolding.

Fabian.lewicki@kraussmaffei.com