Trends & Markets

Cost-efficient lightweight design

| Petra Rehmet

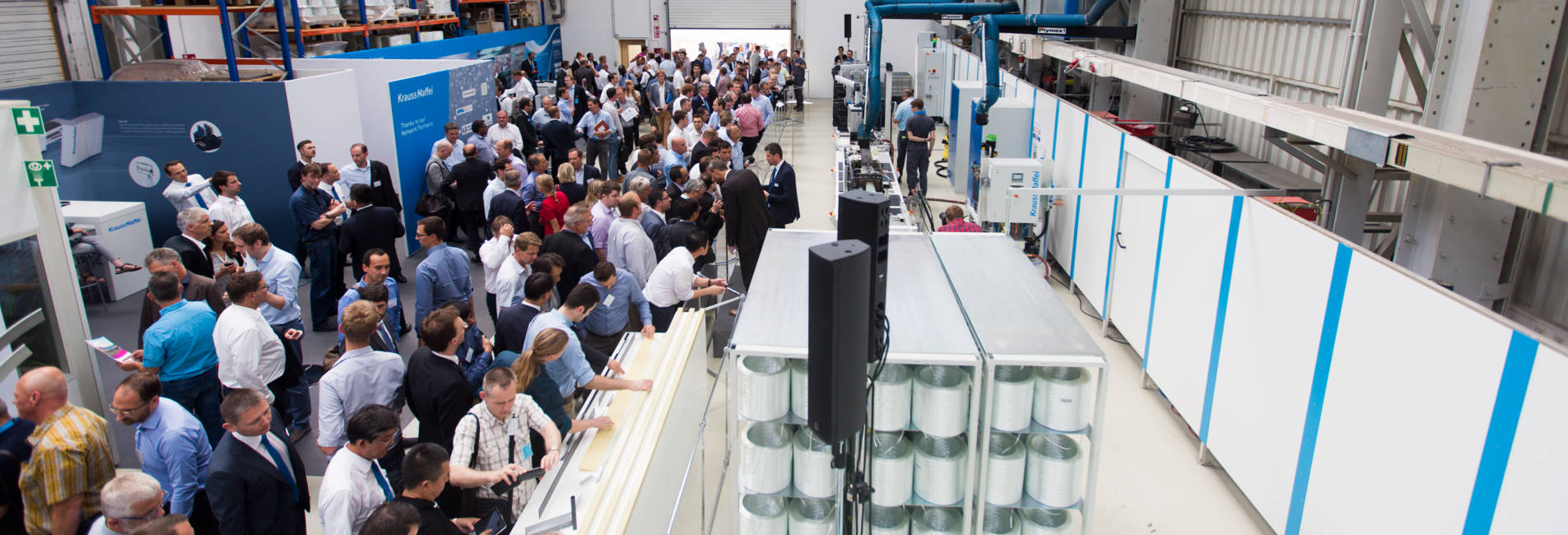

KraussMaffei at Composites Europe

Production processes ready for large series production and groundbreaking lightweight construction: From November 6 - 9 at the Composites Europe Show in Stuttgart, KraussMaffei is presenting solutions for manufacturing fiber-reinforced plastic components.

Thanks to the wide-ranging expertise in the areas of injection molding and reaction process machinery, KraussMaffei is one of the few providers on the market to provide technologies and systems for processing thermoset and thermoplastic matrix systems from a single source.

Automation drives innovation

The market for composites continues to develop very dynamically. Important drivers of innovation are automated processes that allow manufacturing that is ready for large series production. In light of this fact, KraussMaffei is continually optimizing their systems and processes while expanding their portfolio. One example is the iPul pultrusion system, the first complete system for continuous pultrusion of straight and curved profiles. Featuring production speeds up to two times faster than the conventional tub or pull-through process, it opens up completely new markets for pultrusion. Short cycle times, high reproducibility and a high degree of automation distinguish the five different RTM processes (resin transfer molding) from KraussMaffei. One focus at the Composites Europe is the wetmolding process. It distinguishes itself through a simplified process chain—the preform process is completely omitted – and offers a cost-effective alternative for manufacturing new lightweight components, especially in vehicle manufacturing.

Thermoplastic lightweight construction is up and coming

The FiberForm process deals with processing thermoplastic matrix systems. FiberForm is the thermoforming and over-molding of organic sheets, platen-shaped semifinished products with continuous fibers made of glass, carbon or aramide that, for example, are embedded into a thermoplastic matrix made out of polyamide (PA) or polypropylene (PP). In this process, these semifinished products are first heated, reshaped in the injection mold and then back-injected with polymer, with or without fiber reinforcement.

Since the market launch at the K 2010, we have consistently further developed the FiberForm technology, and today we offer our customers a series solution.

KraussMaffei at Composites Europe, Hall 7, Booth C51

Contact

philipp.zimmermann@kraussmaffei.com