Trendgineering

"Efficiency meets Sustainability"

| Petra Rehmet

KraussMaffei at Fakuma 2021

"Efficiency meets sustainability" is KraussMaffei's motto at the Fakuma trade show in Friedrichshafen, Germany (October 12-16, 2021. Front and center are cost-effective system solutions for medical technology, logistics packaging, technical appliances and lightweight construction, which allow for a measurable increase in efficiency and sustainability, for example through the use of high percentages of recycled material.

The solutions presented at Fakuma are completely geared toward "Efficiency meets sustainability" and have a clear focus on output maximization, high product quality, reduction of life cycle costs and ensuring sustainability.

"As a comprehensive solution provider, our goal is to support our customers sustainably in achieving business success. We combine our machine and application technologies with suitable digital solutions and products to generate clear added value for our customers along the entire value chain.“Dr. Volker Nilles, Executive Vice President Division New Machines

This year, KraussMaffei has made the conscious decision to have an all-digital presentation at Fakuma. "Since the situation has become challenging due to the COVID pandemic, we decided on this kind of trade show appearance early on and used the time to strengthen contact with our customers through digital Pioneers!Talks, road shows and personal conversations. Directly after Fakuma, we are planning further local Pioneers!Table events for our customers in Europe," says Nadine Despineux, Executive Vice President of the Digital and Service Solutions division.

Level up your technology – More efficiency and sustainability in injection molding and in reaction process machinery

Efficiency and sustainability are the focal point of the system solutions of Injection Molding Machinery, Reaction Process Machinery, Automation and Digital Solutions. Wherever large logistics packaging materials are concerned, such as pails, boxes or pallets, plastic processors benefit from higher outputs thanks to the high plasticizing capacities of the MX and GX series from KraussMaffei. The BluePower technology ensures excellent energy efficiency. Furthermore, the APC plus machine function permits safe processing of high percentages of recycled material. The shot weight remains constant at all times. The outcome is an extremely high yield of good parts of up to 100 percent, without production interruption.

In the Medical Technology business area, KraussMaffei demonstrates – using the example of a micromembrane like the ones currently used for vaccination doses – how to implement the processing of liquid silicone (LSR, Liquid Silicone Rubber) successfully, safely and cost-effectively, even in micro-injection molding. The application on the PX 25 SilcoSet is cleanroom-compliant according to class ISO-7 in accordance with DIN EN ISO 14644-1 and allows for high shot weight consistency, thus maximizing the yield of good parts thanks to APC plus. The high degree of automation and the data transparency throughout the process ensure cost-effective and safe production.

Complex connector fabrication made easy

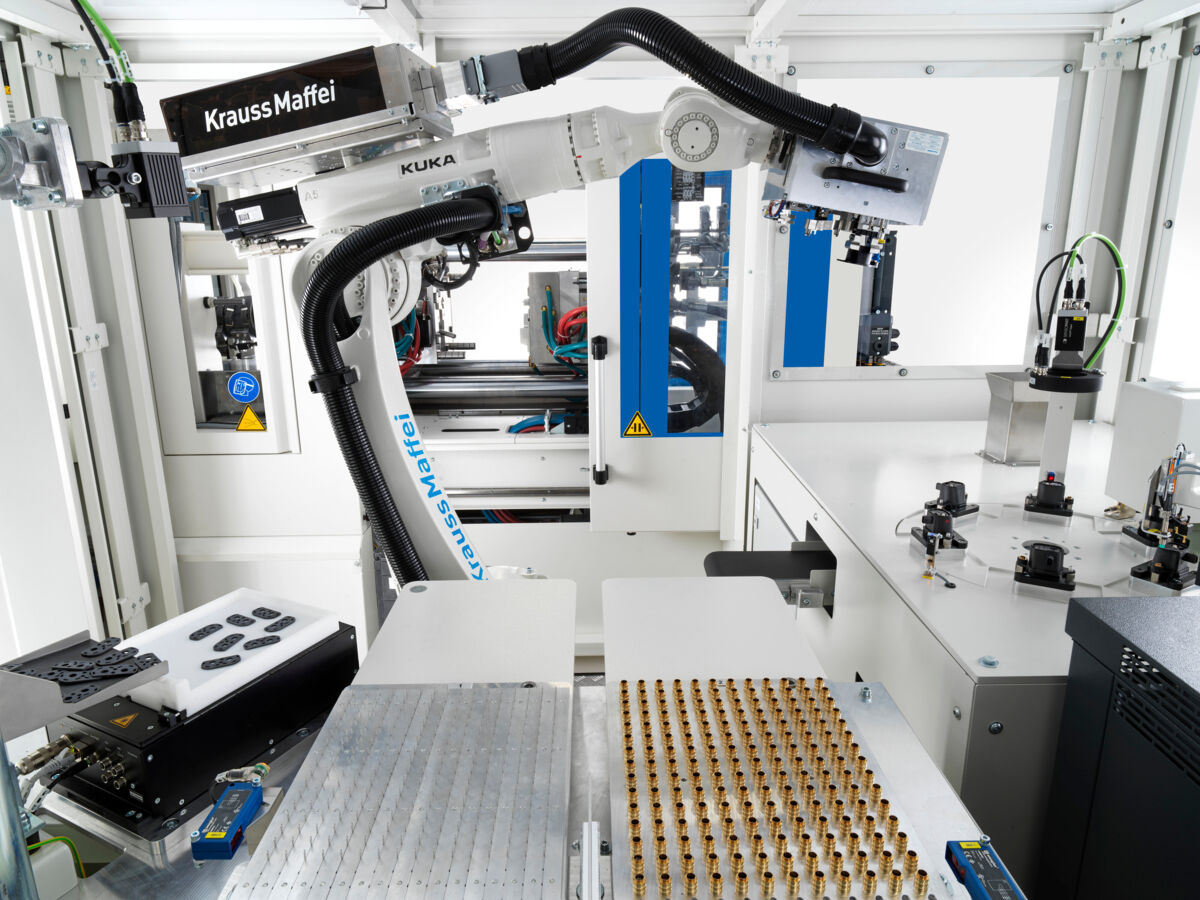

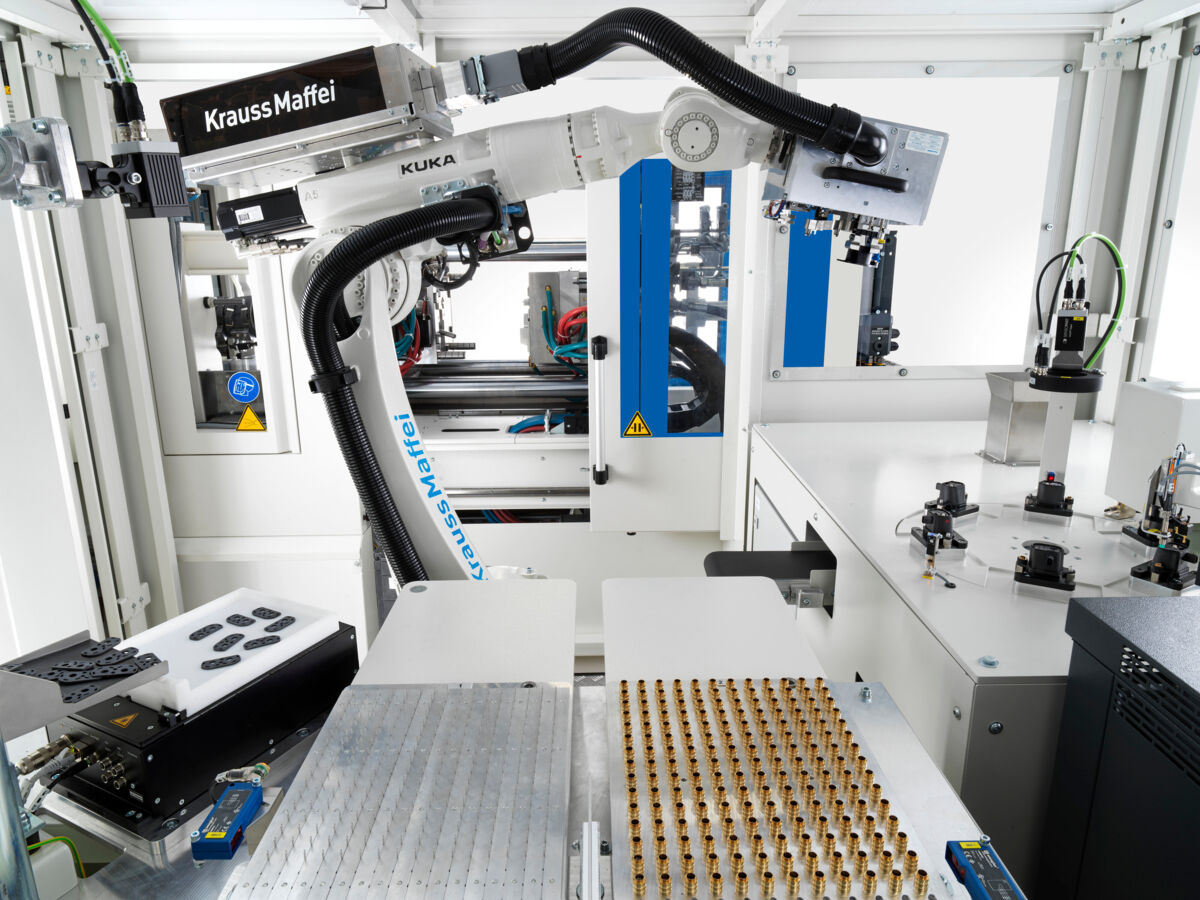

The injection molding machine with docked automation cell embodies maximum precision with minimum footprint

Micro-injection molding with high precision using liquid silicone:

The PX 25 CleanForm for manufacturing micromembranes for vaccination doses in medical technology

In the business of Technical Appliances, KraussMaffei demonstrates – using the example of an intricate connector with four metal inlays – how an advanced, completely tested and ready-to-install component can be realized at low part cost. The all-electric injection molding machine PX 161 with matching automation offers maximum precision while taking up minimal space as a result of the space-saving integration of the automation, high efficiency in the placement and overmolding of the metal parts as well as an extensive inspection routine.

More efficiency in PUR processing and lightweight construction

The RimStar Smart mixing and metering machine embodies higher efficiency in PUR processing. Coming with requirements-based equipment options, it brings exactly the right technology at the highest level of quality for series production as well as for small batch sizes. This means users can offer their customers new products at low part costs. The footprint of just 4.8 m², the excellent price/performance ratio and the user-friendly concept make production with the RimStar Smart particularly efficient and sustainable. The high quality of the components ensures process stability and high availability.

With the motto “all the steps in one”, KraussMaffei will be demonstrating at Fakuma how production processes for complex composites lightweight components can be more efficient, from the concept all the way to series production. KraussMaffei has technologies for the complete production chain for plastic components, from foaming, fiber composite and injection molding to moldmaking and component post-processing. This extensive expertise allows KraussMaffei to provide complete manufacturing solutions that are cost-effective and sustainable at the same time.

Mixing and metering polyurethane in limited space

The RimStar Smart pumping machine requires only 4.8 m² for its core components.

Boost your performance – Digital solutions with customer benefits throughout the lifecycle

Digital solutions from KraussMaffei stand for a high machine availability, high product quality and low manufacturing costs, thus allowing a competitive edge to be gained. At Fakuma, KraussMaffei demonstrates new solutions for customer interaction along the entire value chain.

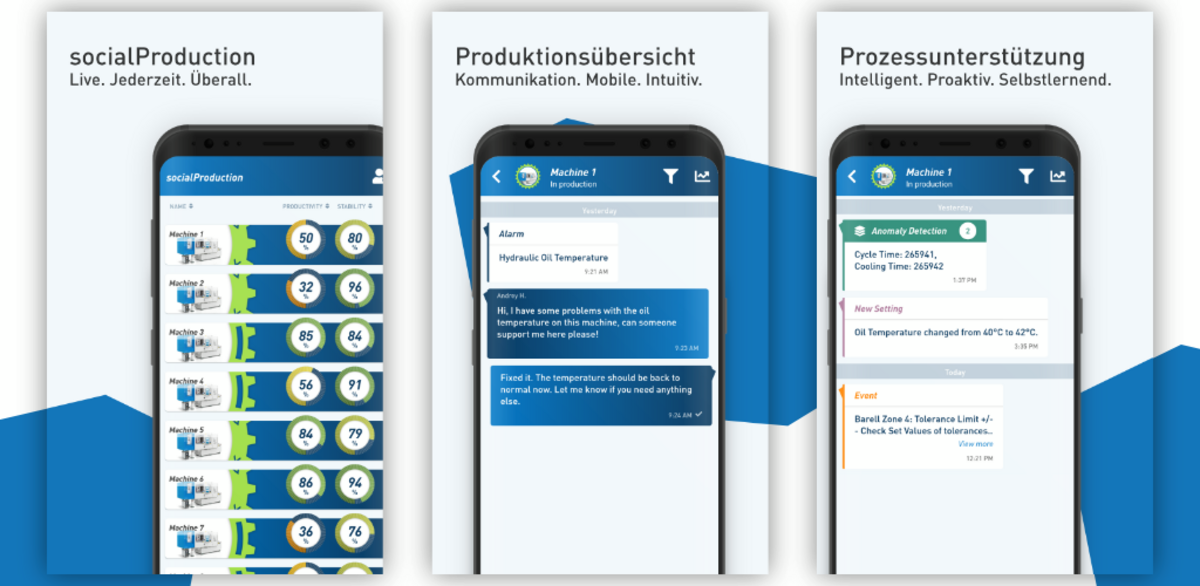

With socialProduction, the mobile app and Web application for injection molding machines, KraussMaffei combines the advantages of social media with cutting-edge production monitoring technology. The machines report to the users live in secure chat rooms. Working autonomously, socialProduction detects deviations in the production process at an earlier stage than ever before.

liveCare is the upcoming KraussMaffei solution for status-oriented maintenance. Seamlessly integrated into socialProduction, wear statuses are continuously monitored and visualized.

Production monitoring at any time and anywhere

socialProduction as a desktop, smartphone and tablet application

Secure remote support is one click away

smartAssist as a desktop, smartphone and tablet application

The cloud-based remoteSupport solution supports all series and technologies from KraussMaffei in any place and at any time. This does not only minimize downtimes, but also service costs. In addition to remote service (remoteAccess) for the machine control system, smartAssist is a video-collaboration app that adds intuitive human-to-human communication.

Interactive AR annotations allow even complex tasks to be shown and explained via smartphone, tablet, computer or smartglasses.

The pioneersClub is KraussMaffei's "digital window". Customers worldwide take advantage of an easy and transparent access to digitalized data such as individualized documentation of the customer's machines, electronic tutorials for machine series as well as quick and easy availability checks and ordering for spare parts and retrofits.

Machine documentation and spare parts procurement, 24/7

The digital pioneersClub service platform

Make plastic green – Highly efficient extrusion technology for recycling tasks

Extrusion lines from KraussMaffei are particularly efficient for recycling tasks. They score with excellent melt homogeneity, a reduction of obtrusive odors and the targeted upcycling.

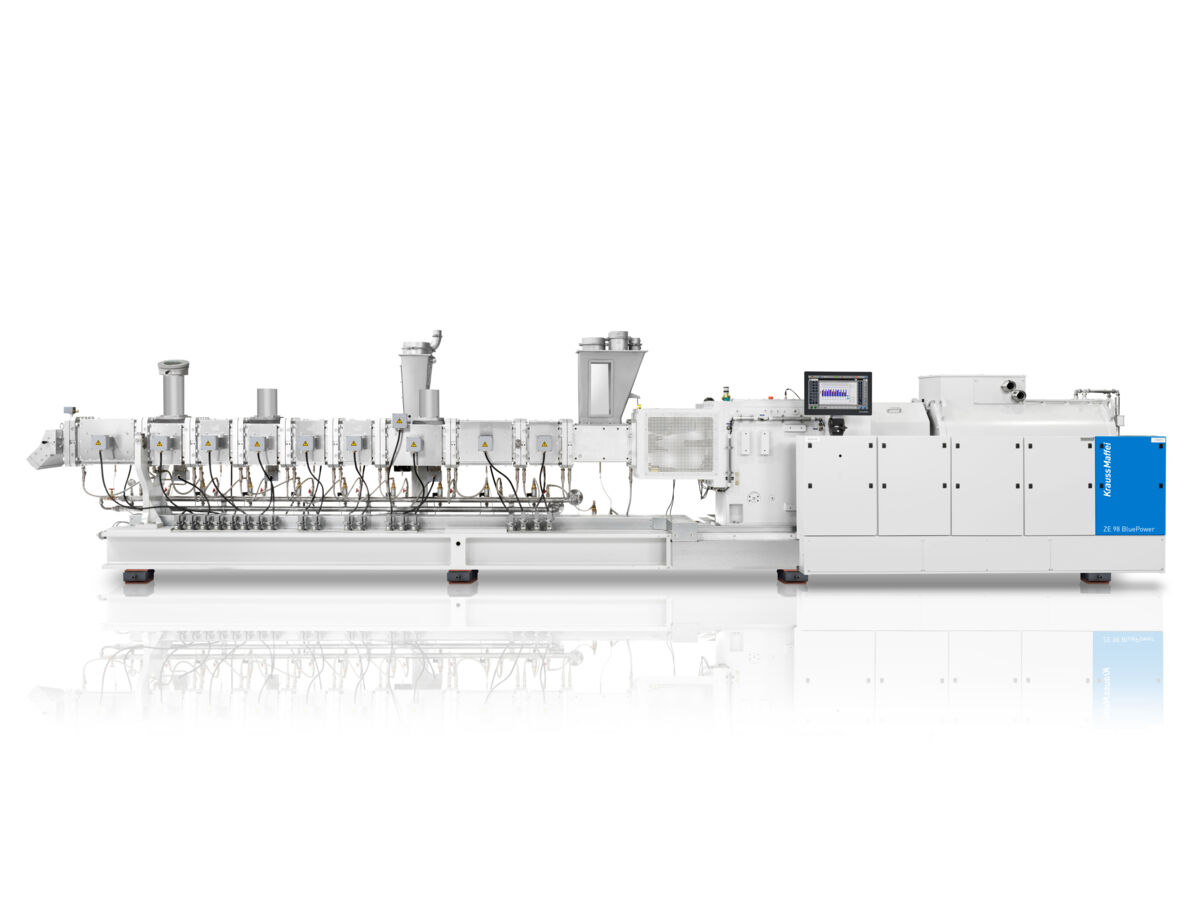

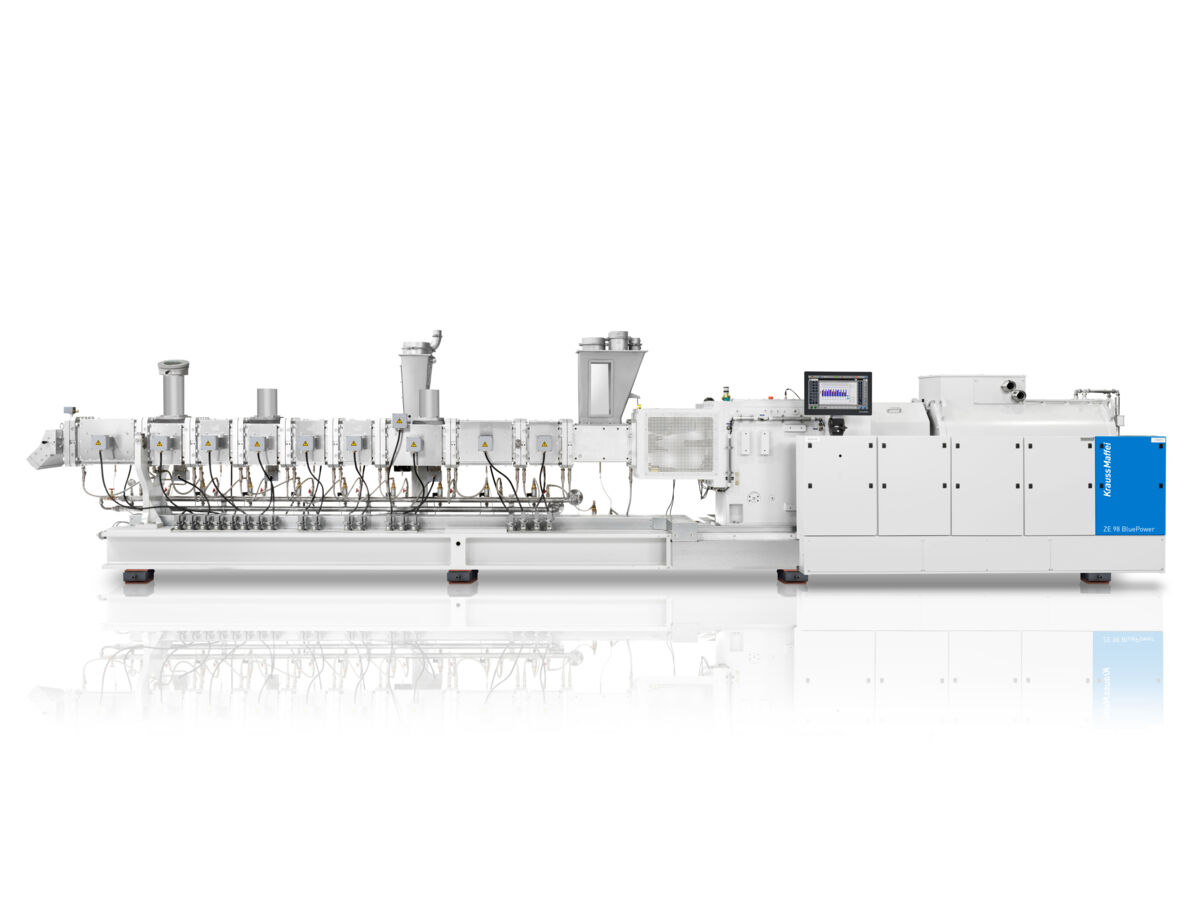

EdelweissCompounding systems are an economic solution for recycling and compounding segregated post-consumer plastics. The ZE BluePower are distinguished by their increased volume and a high specific torque, which allows them to pick up and process the large-volume waste flawlessly. The result is maximum throughput with high quality.

ZE BluePower twin-screw extruders also provide the option for sustainable solvent-based plastics recycling. The objective of this is solvent-free recycled material that can be enhanced like virgin material. Through openings in the housing and a vacuum applied to them, the extruders safely extract the solvents from the melt. Depending on the requirements for the polymer being created, the process involves varying degrees of refinement. For instance, if you want to reduce the residual solvent content in the material from the original 30 down to 2 percent, a twin-screw extruder is sufficient. If degrees of purity in the ppm range must be reached, a twin-stage cascade is recommended.

Cost-effective recycling

The ZE BluePower twin-screw extruders are ideal for the recycling steps of plasticizing, degassing as well as re-pelletizing and re-compounding

Whether technologies or applications in injection molding, reaction or extrusion technology – in combination with the appropriate digital solutions, KraussMaffei will be demonstrating what is important at Fakuma using the example of selected system solutions. Maximum output, high product quality with simultaneously reduced life cycle costs and sustainable production. Just "Efficiency meets Sustainability".

KraussMaffei at Fakuma Hall A7, Booth 7303