Trends & Markets

ELIOS 4500 with highly precise and fast thin-wall application

| Michael Birchler

Netstal at Fakuma

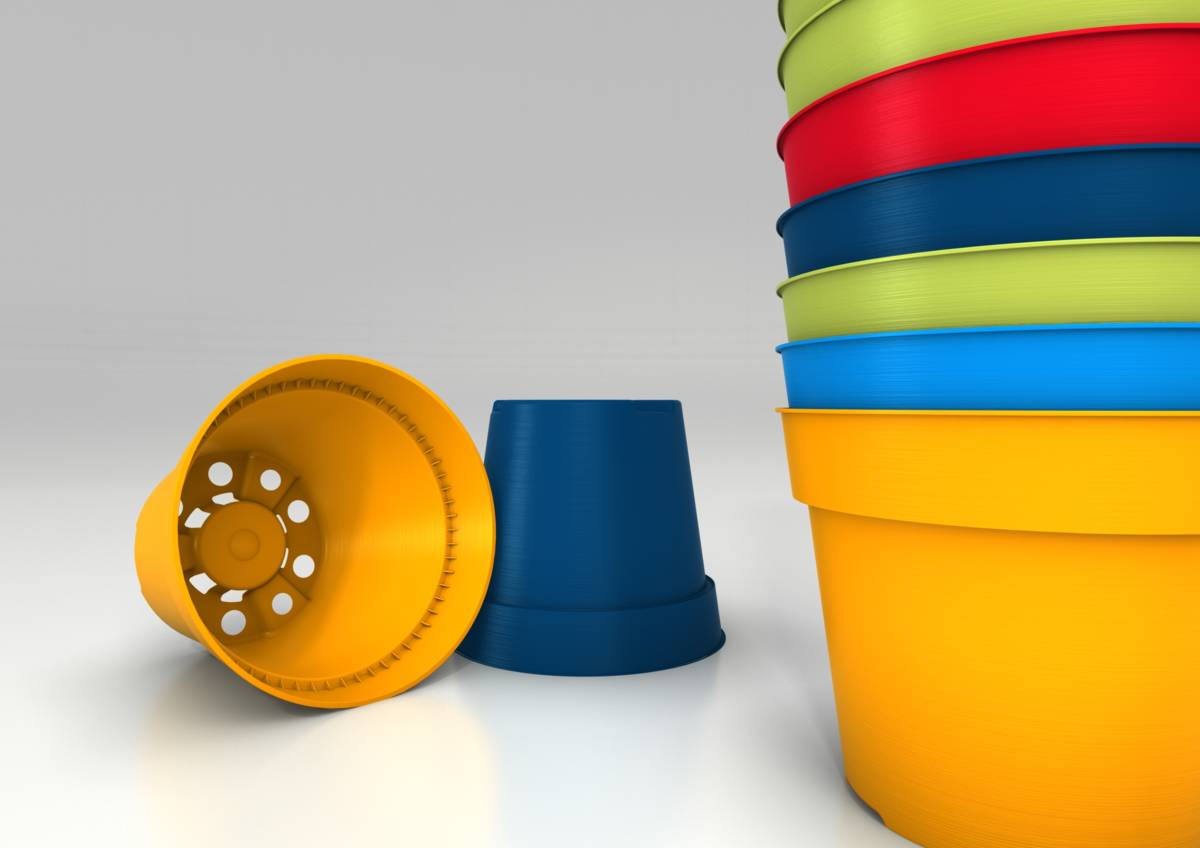

Under the motto "Technology meets Digital", the KraussMaffei Group will present trend-setting industry solutions at Fakuma. On an ELIOS 4500 Netstal shows the production of thin-walled plant pots - and with AnalytiX this can be tracked online at any time.

It will be a highlight at this years Fakuma: the ELIOS 4500-2900 from Netstal. The 6-cavity mold comes from Glaroform. 12cm polypropylene plant pots are produced with a cycle time of around 3 seconds. In order to make sure that things don't get boring, the pots will be injection-molded in various colors. UCC is providing the color master batches. A Brink Automation robot will remove and stack the finished pots. Thanks to the outstanding injection performance, the flow path to wall thickness ratio is 331/1.

"The ELIOS series has been a total hit with regard to performance, precision and energy efficiency. Our customers from the demanding packaging industry heap effusive praise on the series because it gives them decisive competitive advantages"Renzo Davatz, CEO Netstal

Hybrid drive concept for maximum performance and the lowest energy consumption

A key factor for the success of Netstal's ELIOS series is the unique drive system of the clamping unit with electrical movement and the hydraulically supported generation of the complete clamping force. Expressed in numbers using the example of the machine at the trade fair, this means a 1.5-second dry cycle with a clamping force of 450 tons Thanks to a high efficiency and the recuperation of kinetic energy, the operation of the ELIOS machines is also extremely energy-efficient. The consumption of the trade fair exhibit is approx. 0.59 kilowatt hours per kilo of material, which translates to 9 watts per pot.

Mobile production monitoring with AnalytiX

With AnalytiX Netstal users always have their entire injection-molding production at their fingertips in the form of an app. The automated analyses of processes and machine conditions save time and offer efficiency increases. Using intelligent indicators, trends and performance deviations of individual machines can be detected at a glance. Data security is a priority at Netstal. All information is hosted in the secure Netstal cloud in Switzerland and is not accessible to third parties. User management and the granting of access rights is controlled entirely by the customer and can be set up flexibly via the new Netstal e-Service.

Mobile production monitoring

With AnalytiX Netstal users have their production always in sight

AnalytiX demo access

During Fakuma, the ELIOS 4500-2900 will be integrated into the free test access. From October 16 to 20, the machine parameters can be viewed far away from the exhibition. Simply install the app and tap on the demo button under "Login": Apple App Store Google Play Store