Trendgineering

Foamed happiness for hobby gardeners

| Petra Rehmet

Intelligent composter uses MuCell-Technology

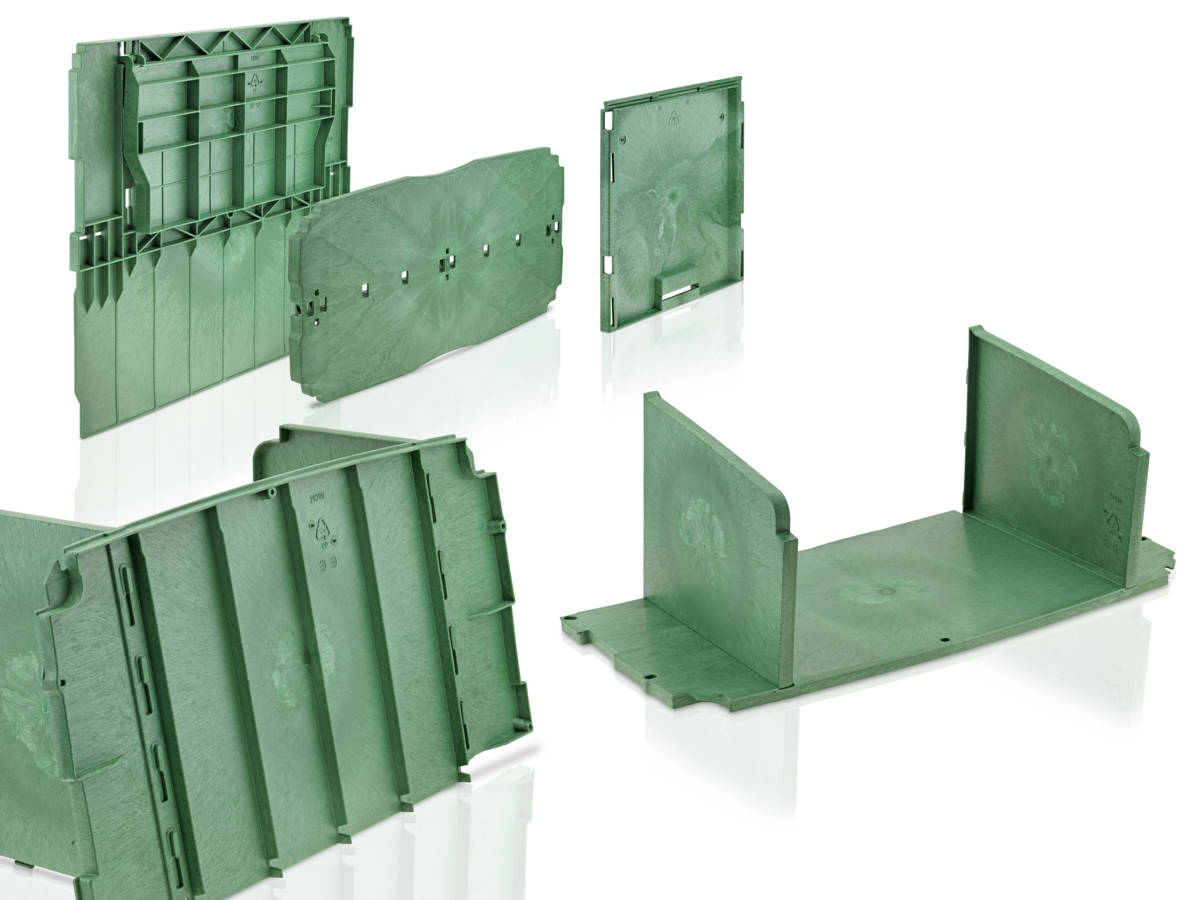

The inside of the patented three-phase composter Aeroplus 6000 is twice as exciting: An innovative multiple chamber system allows a direct conversion of organic waste into high-grade soil. The components consist of MuCell-foamed parts.

The polypropylene composter from the Austrian manufacturer Juwel, which has been on the market since 2011, makes it easy for the hobby gardener to produce his own potting soil, because thanks to a patented three-chamber system the tedious transformation of the decaying matter is deleted and everything takes place cleanly on the inside. Even flying insects cannot access the emerald green garden gem. The concept received a special mention at the Red Dot Design Award.

When Juwel came across KraussMaffei, it was initially in relation to another product. Garden elements, as used for borders of flower beds or raised beds, which until then were chemically foamed, were to be changed to physical foaming. For the chemical foaming a propellant is still mixed with the polymer, which decomposes during plasticizing and emits a gas (generally carbon dioxide). Andreas Handschke, Technology Manager for MuCell at KraussMaffei, describes the problem: "During this decomposition fission products such as heavy metals also arise, which are barely controllable and must be increasingly viewed with a critical eye within the framework of the REACH regulation. The American Food and Drug Administration (FDA) also sets strict requirements for items that come into contact with food, which might well be the case with raised beds."

The Aeroplus 6000 makes gardeners' dreams come true:

Fill organic waste at the top and remove the ready soil at the bottom. The micro-organisms work in the intermediate levels

No annoying by-products

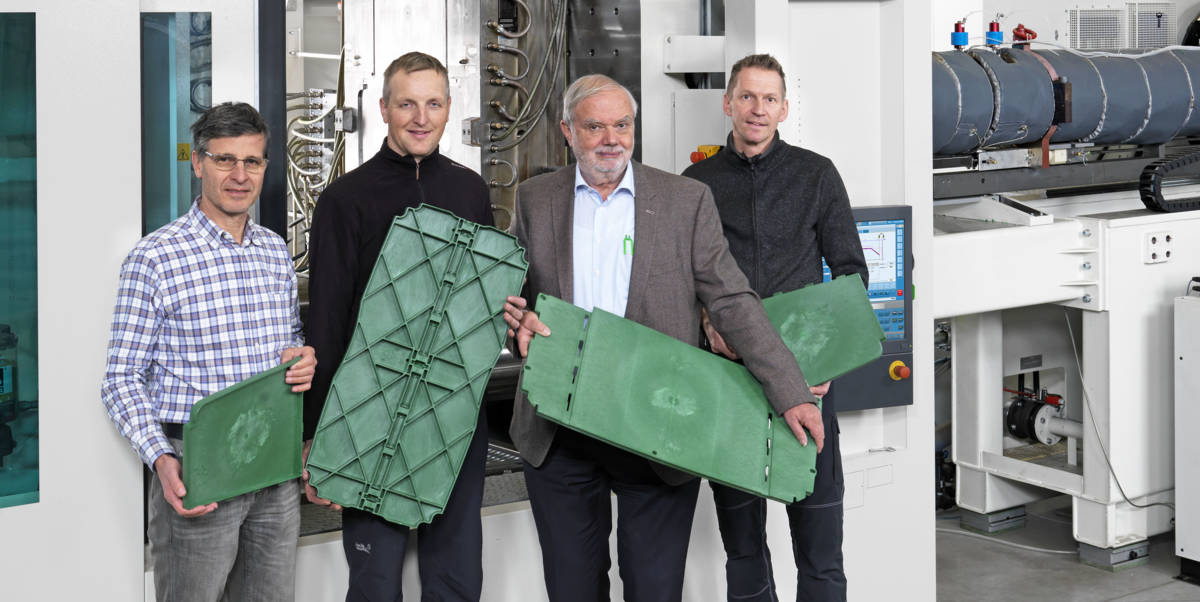

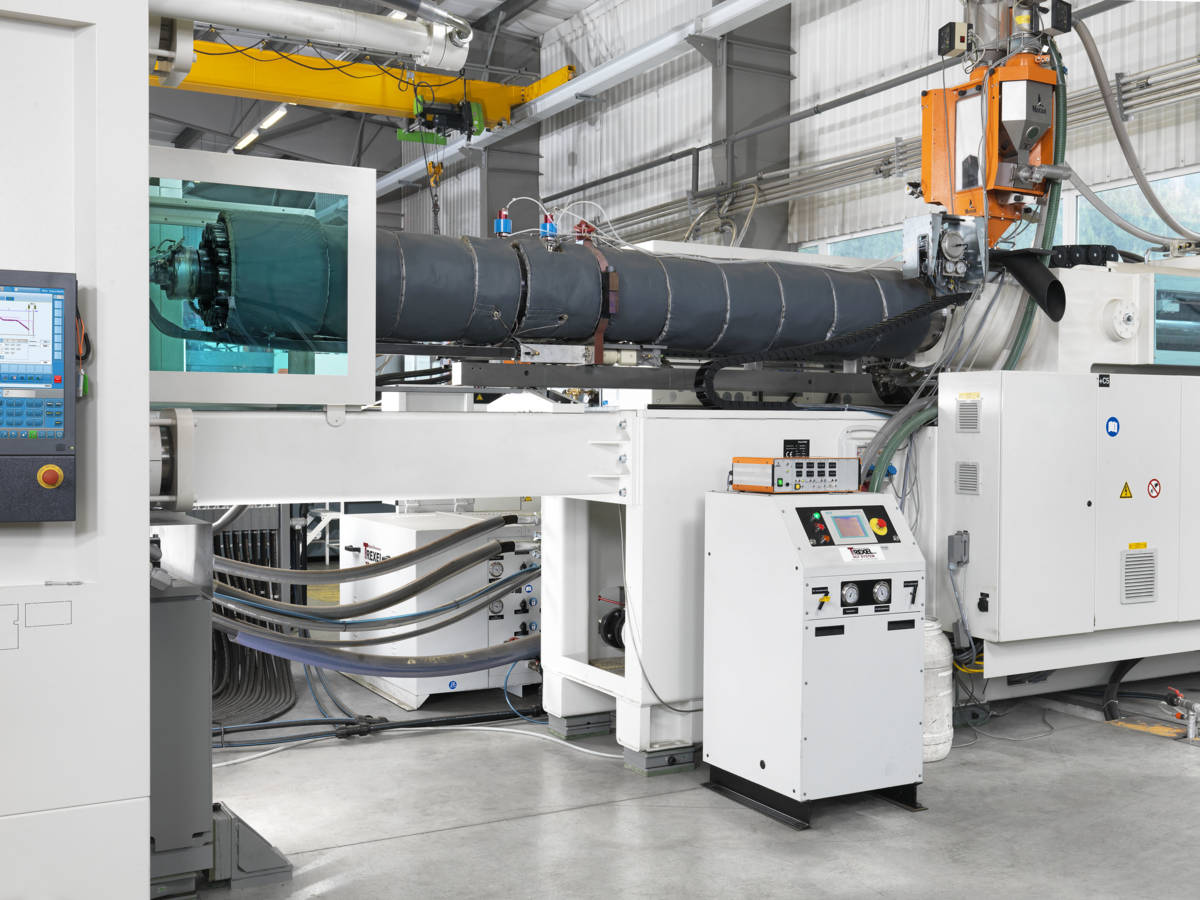

Whereas during the physical foaming with MuCell, nitrogen is dosed directly in the screw and then creates the desired foam structure in the component. No annoying by-products are produced in the process. KraussMaffei is a system partner for the MuCell technology developed by Trexel, and is one of the few companies to offer both process and machine engineering from a single source. As the tests were successful thanks to the Munich-based experts, Juwel decided to purchase a CellForm machine from KraussMaffei and as a first step go into production with non-visible components, which is why the Aeroplus 6000 was redesigned accordingly.

"MuCell offers fantastic possibilities for thinner wall thicknesses thanks to the improved flow capacity."Heinz Wüster, Managing Director Juwel

Heat exposure is also important for successful composting, and it is therefore a good idea to use foamed components and their additional insulation. As in recent years the material prices both for new goods and recycled material also rose, but the sales market does not accept higher prices, the company from Imst looked for ways to increase productivity. The composter was designed for chemical foaming and in another step for MuCell, which no longer meant significant effort. Compared to compact injection molding, around 11% of material can now be saved and with the higher drive energy represents an advantage of 7% over chemical foaming.

Testing MuCell for visible components

Juwel Managing Director Heinz Wüster is impressed with the advantages of the technology: "MuCell offers fantastic possibilities for thinner wall thicknesses thanks to the improved flow capacity. It's called rethinking the design concept: One only strengthens the areas that require it mechanically because uniform wall thicknesses are no longer required for purely processing reasons. The thinner walls are also considerably lighter thanks to the foam structure." For the garden specialist this means an important step towards being prepared for the future, and in keeping with this other items are now also to be switched to MuCell. Therefore, the MX 1000 serves not only daily production, but also the exploration of new applications – with active support from KraussMaffei and Trexel. For instance, we are working together to also manufacture visible components through selective surface technology for which chemical foaming still currently has slight advantages. Wüster praises the cooperation: "We had actually buried the topic of MuCell because earlier tests were unsuccessful. Thankfully we started another test with KraussMaffei because the physical foaming brings us significant advantages."

Contact

andreas.handschke@kraussmaffei.com