trendgineering

For the “Crème de la Crème”

| Christina Langbein

Novassu produces closures for premium cosmetics

Novassu’s customers represent the “Crème de la Crème” of the cosmetics industry. They need elegant perfume bottles with crystal-clear designer caps made with plastics from chemical recycling. The French closure specialist Novassu shows how it's done with support of KraussMaffei.

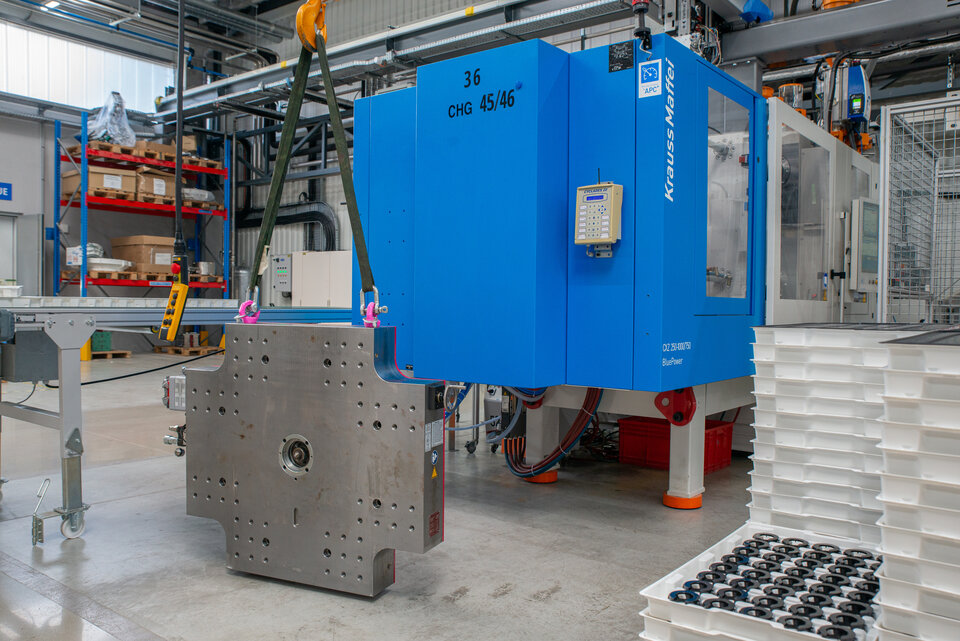

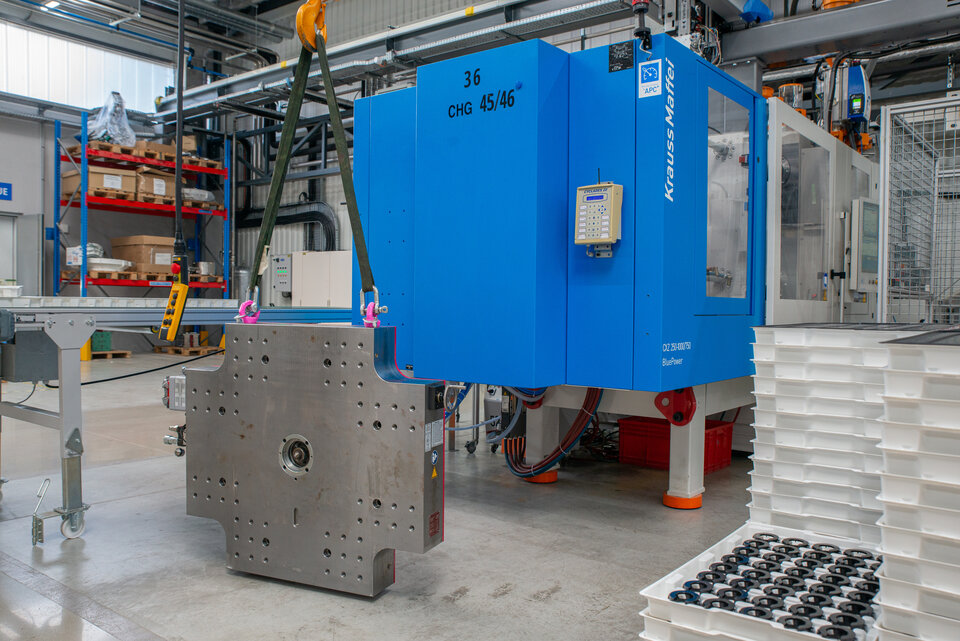

Chanel, Givenchy, Estée Lauder, and Coty, which also manufactures for PUIG: anyone who has made it in this world must be operating at the highest level. Novassu supplies closures of all kinds for luxury cosmetics lines, whether for perfume bottles, lipsticks, or makeup compacts. Managing Director Gérald Paris is always interested in technical innovations, which is why a new CXZ 250/1000-750 Multinject from KraussMaffei was recently commissioned. In addition to 2K sandwich molding, the machine also supports index plate technology.

The CXZ 250/1000-750 Multinject features a sandwich platen, allowing recycled material to be injected as a core layer within skin material.

This machine is equipped with a sandwich platen which offers the possibility, for example, to inject a layer of recycling material inside skin material. The sandwich plate is a very flexible solution to easily switch the sandwich process to a usual 2K process (nothing to disassemble on injection unit side) and also to move towards the use of mono-material equipment.

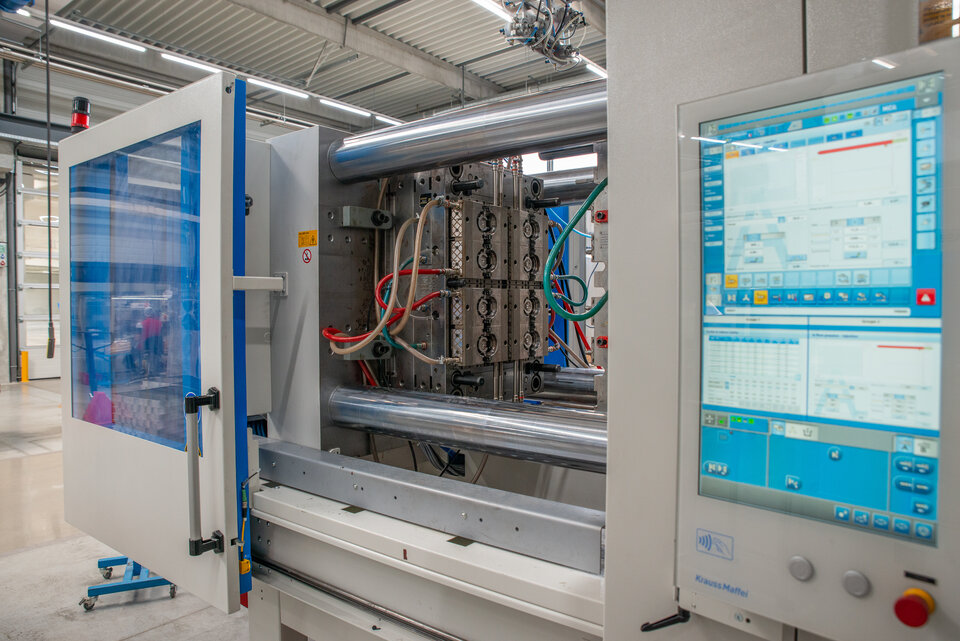

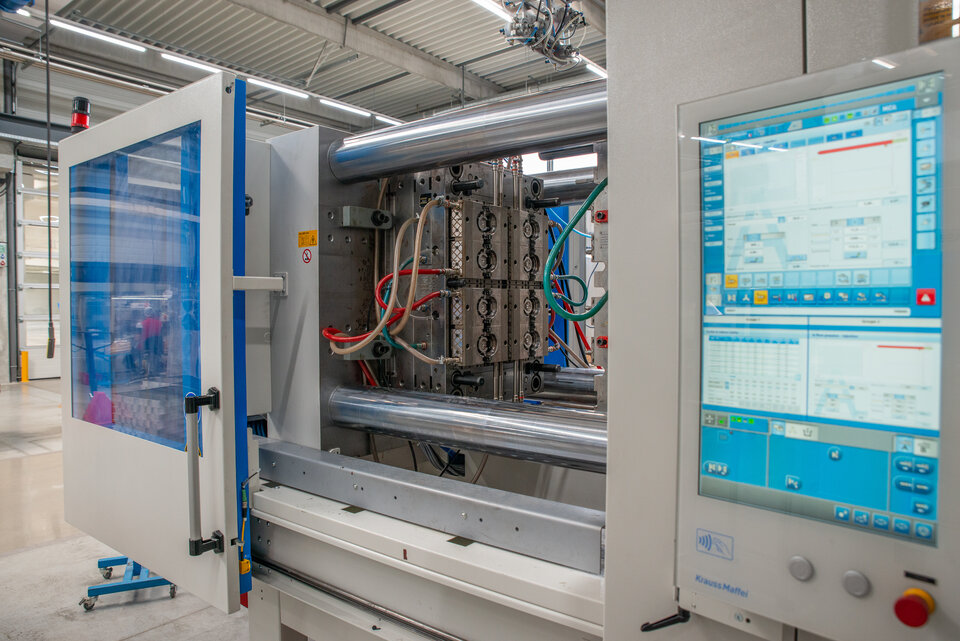

Index plate molds can be driven using the machine-side index plate drive from KraussMaffei. It can be used for overmolding or for multilayer process. This integration of several technologies on the same machine was the main driver for Novassu to choose KraussMaffei.

A look into the mold: The CXZ 250/1000-750 Multinject handles both overmolding and multilayer processes with ease.

We only invest in machines that offer us maximum flexibility – no off-the-shelf. Our business is continuously evolving, and we need a strategic partner who can also bring in experience from other industries.Gérald Paris

Managing Director Novassu

More recyclates, more design freedom

The current project uses sandwich injection molding, a process already established in other sectors: recycled material inside, new material outside. The idea for the crystal-clear, cube-shaped cap came from Novassu itself – the company not only works on commission but also offers its own designs.

With a recycling content of 30 percent, the 2K closure is intended to contribute to sustainability. It’s also a true design highlight. And since the machine is already prepared for a third component, further creative concepts are within reach – for example, a marble effect inside the cap by alternating color injections.

From Chanel to Givenchy – Novassu creates premium closures for the world’s leading luxury cosmetic brands.

At its site in Molinges, near the Swiss border, Novassu operates around 20 KraussMaffei machines from the CX and PX series, with clamping forces ranging from 500 to 4,000 kN. 60 employees produce components ranging from approximately 10 to 100 millimeters in size. In addition to injection molding, Novassu offers various finishing processes such as hot stamping.

Where precision meets elegance: A view of Novassu’s new production site in Molignes/France:

From ionomer to standard thermoplastics

As these are cosmetic products, the raw material always plays a crucial role. It must be FDA-certified, and recyclates typically face strict scrutiny. However, since materials like PET from beverage bottles benefit from excellent recycling systems, it makes sense to use them in areas that don’t come into direct contact with the perfume or cream.

Novassu is currently undergoing a major shift: moving away from the frequently used ionomer toward standard thermoplastics. The ionomer can only be chemically recycled, whereas PET with minimal contamination can be recycled mechanically. Since this copolymer requires the high pressure of standard injection molding machines, the change in material also paved the way for KraussMaffei's fully electric PX.

Every part a good part: APCplus ensures consistent shot weights by adjusting switchover and holding pressure based on melt viscosity — especially valuable when processing recyclates.

Since 2019, all machines have been equipped with the APCplus function from KraussMaffei, which ensures extremely consistent shot weights by adjusting the switchover point and holding pressure for each shot based on melt viscosity. This is particularly valuable when working with recyclates, which often show greater batch-to-batch variations.

With APCplus, we’ve significantly reduced scrap and improved our product quality. This is a clear benefit also in terms of cost-efficiency.Gérald Paris

Managing Director Novassu

Built for growth

Gérald Paris has ambitious plans for Novassu, aiming to expand the fleet with additional injection molding machines. The newly built 3,000-square-meter hall, completed last year, provides ample space for this. And technologically, there is more to come.

KraussMaffei offers several processes that are very interesting to us, and where we can benefit from experience gained in other industries. One of these is already in our sights.Gérald Paris

Managing Director Novassu

Looking ahead to exciting new projects: Gérald Paris (Managing Director, Novassu) and Hervé Dumurgier (Head of Sales, KraussMaffei Group France).

The partnership between the two companies is sure to remain fruitful well into the future.