trendgineering

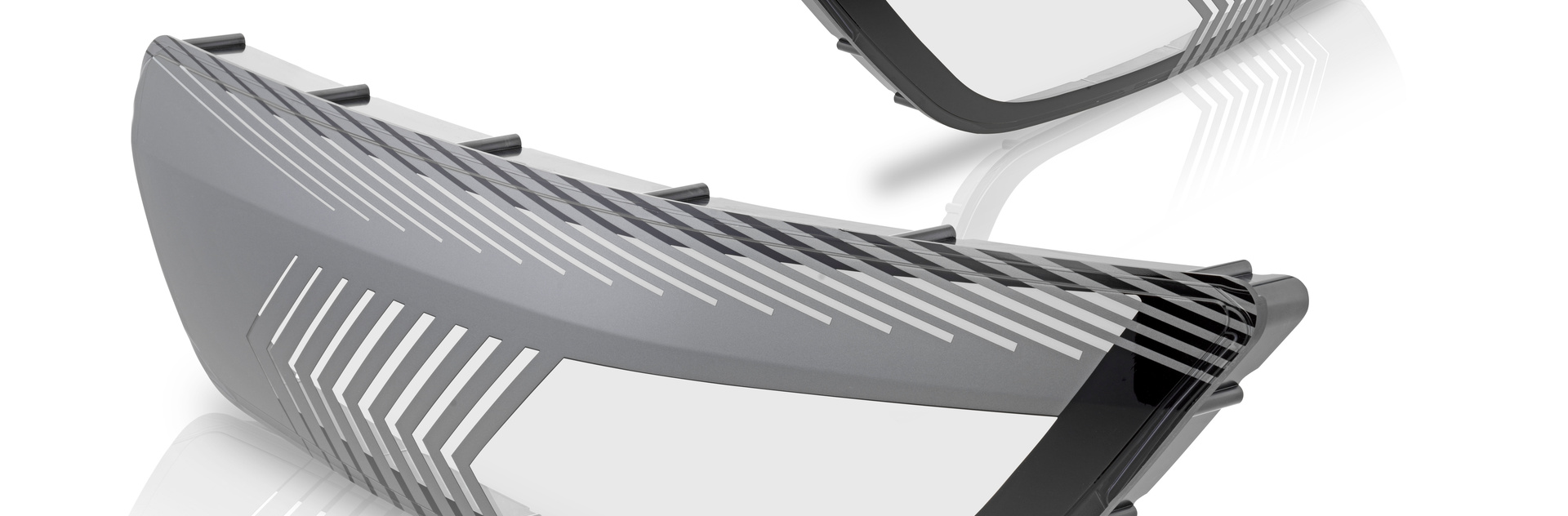

"FrontIQ Light": Shaping the Headlights of Tomorrow

| Julia Reich

KraussMaffei's ColorForm technology as a game changer

Headlights have long been more than just a source of light. They're a high-tech mix of design and safety features. When driving through the streets today, you can often tell which brand a car is by its light signature. With “FrontIQ Light,” KraussMaffei is showing at K 2025 what the headlights of the future could look like.

At the heart of this innovation is the ColorForm technology. This process involves putting a polyurethane surface on a thermoplastic component right in the injection mold. What used to be a complex process involving subsequent hard coating is now achieved by an inline PUR layer – precisely controllable down to a tenth of a millimeter.

This saves costs, creates new haptic effects, and ensures a surface that's resistant to UV radiation, stone chips, and chemicals, and even heals itself in the event of fine scratches.

Unlimited design freedom

Things get really exciting when it comes to design: the integration of printed design films into the mold creates brilliant depth effects, individual patterns, and surfaces that are immediately protected – without any additional coating processes.

The real world premiere: film deep drawing directly in the mold. What previously required several process steps now happens inline and with high precision. The 2D film is automatically preformed, drawn into the third dimension in the mold, and perfectly combined with transparent and black polycarbonate. The result: maximum design freedom and a distinctive look.

The globally unique deep-drawing of film in the mold is the key to maximum precision and opens up completely new possibilities in luminaire design.Andreas Bierbaumer

Manager Business Development Technology

It's automated, clean, and efficient

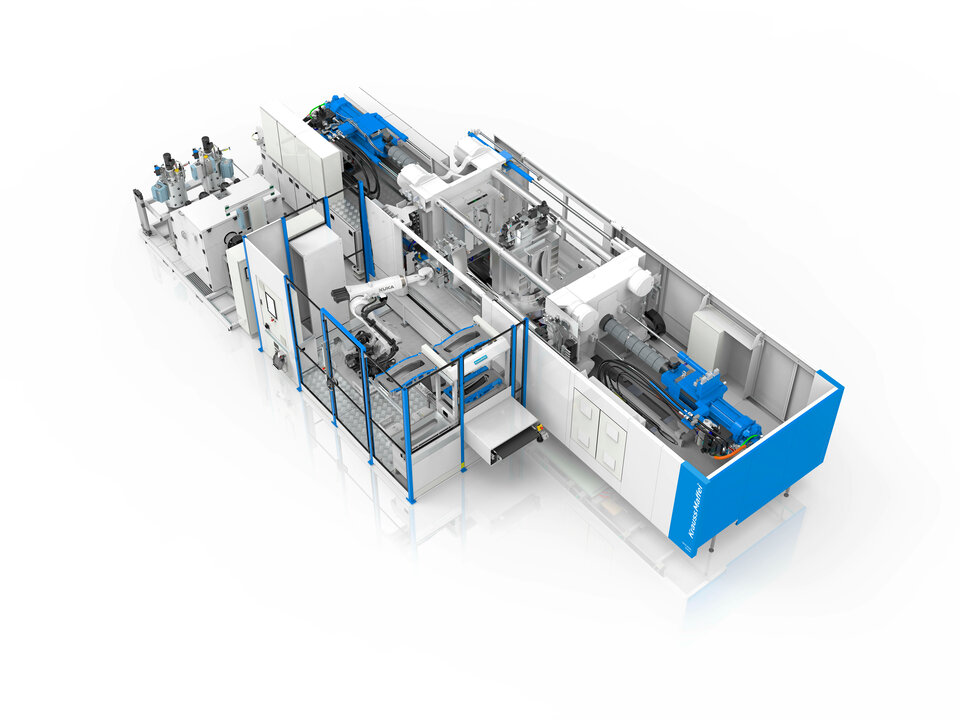

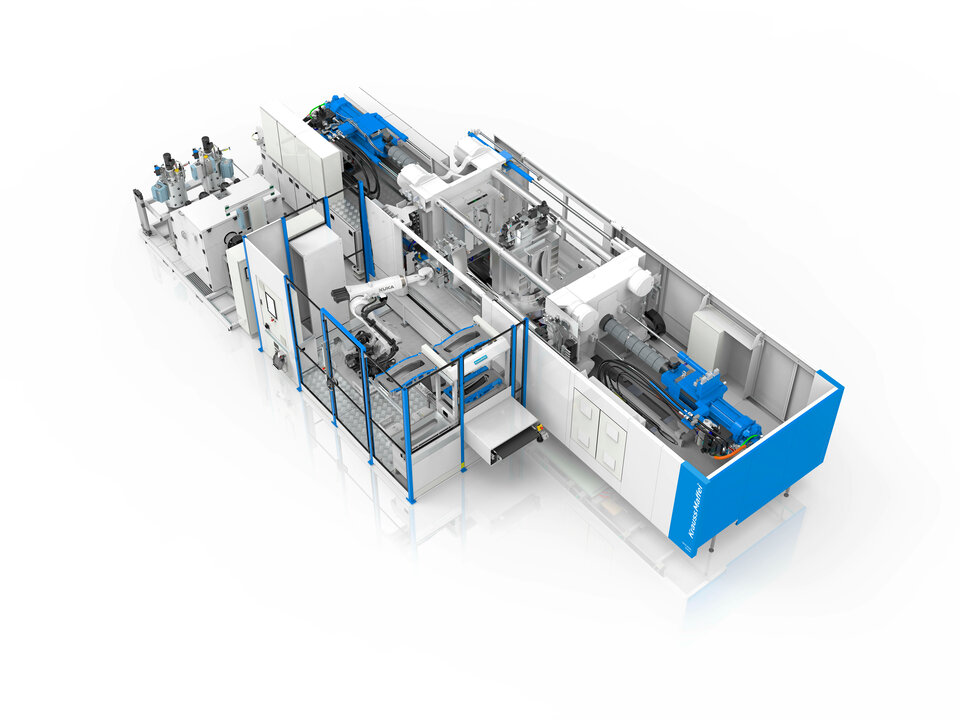

To ensure everything fits with millimeter precision, KraussMaffei has developed its own automation solution. The films are first cleaned, then positioned with exacting accuracy, and finally formed. This continuous process guarantees clean, error-free results — with maximum efficiency.

Turnkey solutions from a single source

The big advantage for customers: KraussMaffei delivers the complete solution. From automation and PUR technology to injection molding technology, everything comes from a single source – and is perfectly coordinated. This creates a process in which design, function, and protective coating merge directly in the mold.

Live at K 2025

Visitors to K 2025 can experience “FrontIQ Light” live. We'll be presenting a 720-millimeter-long 3K demonstrator on a GXW 650 with a turning plate, together with our partner LEONHARD KURZ. If you're interested in seeing how the front light of the future is created, you won't want to miss this.