Insights

GX speed makes packaging faster

| Petra Rehmet

KraussMaffei at NPE

At NPE in Orlando, KraussMaffei is debuting a GX 900 with the new speed option which makes packaging and logistics applications faster.

In addition to high injection speeds, the primary requirement for thin wall articles for packaging and logistics solutions are short cycles. For this reason, KraussMaffei has added a new speed option to its proven 2-platen GX series which offers customers an optional choice of different injection speeds of up to 700 mm/s depending on the injection unit. The GX 900-12000 at NPE also includes faster clamping speeds of up to 0.45 s. "The GX with the speed option features an efficient, cost-effective and attractive alternative to manufacturing large components for the packaging and logistics industries – a market that has undergone continuous growth in the USA in recent years," says Paul Caprio, President of US subsidiary Krauss-Maffei Corporation in Florence, KY.

The speed option really showcases its advantages at opening widths of 350 to 400 mm. In this way, the kinematic unit is similar to comparable toggle machines that also do not reach their maximum acceleration until the opening strokes are large. Enhanced parallel movements on the plasticizing side with the electrically driven plasticizing unit (E-Plast) support the short cycle times. PowerPack III features additional speed options such as a faster clamping force build-up, screw decompression or injection unit movement.

Ideal for large packaging solutions

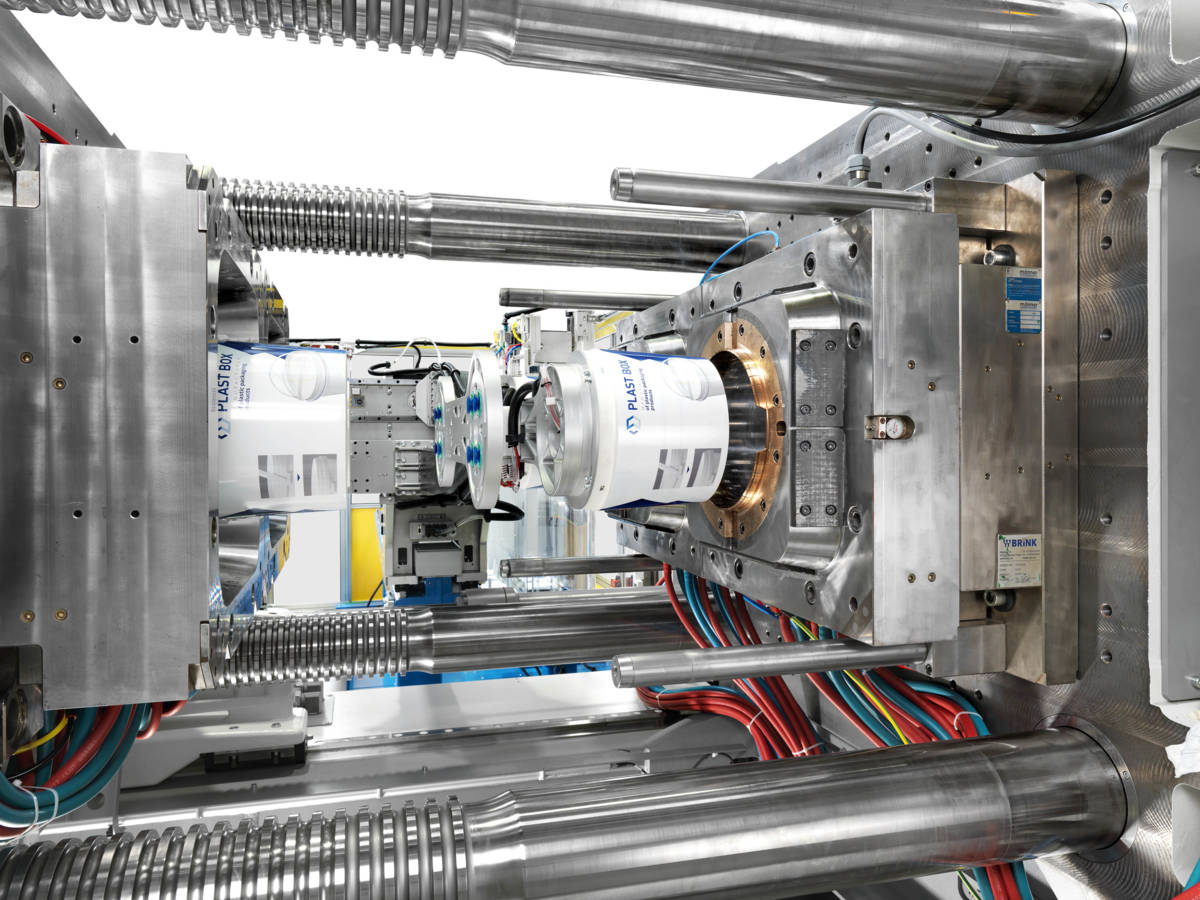

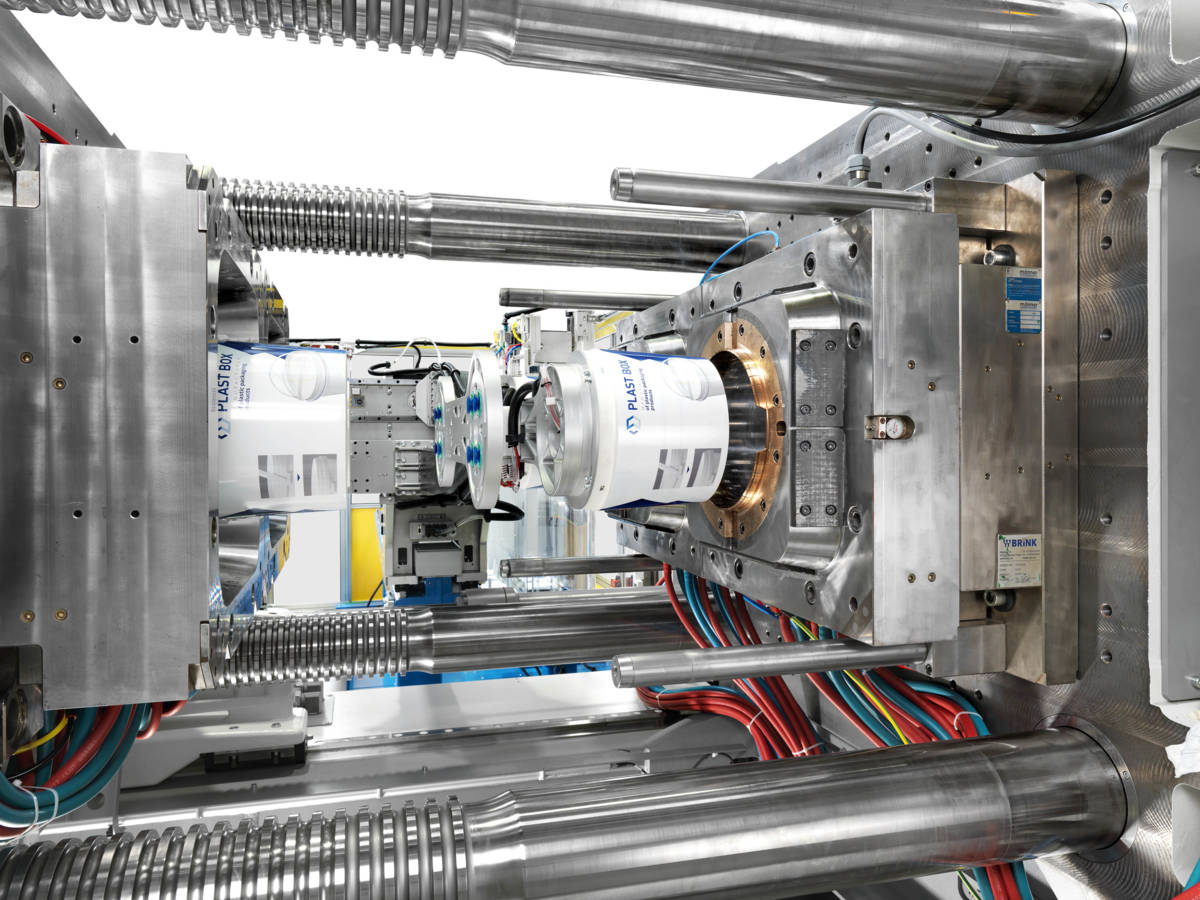

The GX series provides plenty of space for large molds and cooling water systems

At NPE, the GX 900-12000 produces large 20 L buckets in a 2-cavity mold in an in-mold labeling process (IML). Thanks to the speed design, this occurs in short cycle times of less than 14 seconds. The GX 900 also features the proven KraussMaffei HPS high-performance barrier screw, which enables extremely fast melting and high shot weights. Overall, the throughput can be increased by up to 12 percent. "The IML application at NPE is the market debut for the GX series speed option. At the same time, a 20 L bucket is being produced in a 2-cavity mold using the IML process," says Caprio. Until now, these large buckets had mostly been printed. The speed option now enables these buckets to be produced cost-effectively in the IML process.

KraussMaffei at NPE

7 to 11 May, 2018

Hall West

Booth W403