Trends & Markets

High material cost

| Petra Rehmet

Lightweight construction has it rough

How is automotive lightweight construction doing currently and what are the challenges? How does one find the appropriate materials and technologies for specific projects from a wide variety of options? K-Magazine spoke with Stefan Fenske and Sebastian Schmidhuber, experts in composites at KraussMaffei.

ahead

What are currently the greatest challenges in fiber-reinforced lightweight construction?

Stefan Fenske

Most definitely the material prices. This applies to organic sheets, which, in our FiberForm technology are heated, reshaped in the mold and then back-injected with fiber-reinforced polymer, as well as to carbon fiber for reaction engineering processes such as resin transfer molding (RTM). Systems engineering is absolutely advanced and in the area of thermoplastics, is ready for large-scale production, but the material costs still have a significant influence on unit costs.

The FiberForm process

KraussMaffei has further refined the FiberForm process and prepared it for series production

ahead

Which topics are currently being most heavily discussed?

Sebastian Schmidhuber

What is going on in China is extremely interesting. There, the topic of lightweight construction is being driven ahead much more quickly. Beginning in 2019, all automobile manufacturers there must fulfill a 10 percent quota of vehicles with alternative drives if they want to avoid fines. Beginning in 2020, even 12 percent. Chinese automakers are systematically working on weight reduction in order to increase ranges. Therefore, we have recently sold systems for the thermoset wet molding of layered carbon fibers to China. In Europe, however, it seems that larger batteries are favored and a higher total weight is being accepted. In terms of technology, China is ahead of us.

ahead

Is more cost-effective lightweight construction even possible with regard to composites in automotive production? Where is it failing up to now? Are there any solutions in sight?

Fenske

We currently have a FiberForm project with three million door module carriers for a compact vehicle. Quantities such as these are necessary so that the material prices can decrease; there is a correlation. The development in the direction of more lightweight construction can, however, only be driven forward by the OEMs and in particular, by their suppliers. Here, there were indeed good flagship projects, but still no long-term change in thinking.

ahead

Reaction Process Machinery with thermoset plastics or injection molding with thermoplastics: So as a matter of principle, when do you use which technology and which will prevail in the future?

Schmidhuber

We manufacture all important components for both kinds of plastics processing in-house: Metering machines, presses, milling centers for Reaction Process Machinery and classic injection molding machines with advanced automation solutions. Therefore, we have a good, and above all, impartial overview of the respective technologies. Of course, each project must be thoroughly conceptualized, but in general one can say: The higher the mechanical requirements and the more complex the geometry, the more probable it is to use reaction engineering processes with thermoset plastics. When very high quantities and cost-efficiency are priorities, this plays to the highly automated injection molding's strengths. The required surface finish question also plays a role.

Floor cover for the vehicle interior of the BMW i8

Wet molding offers an economical alternative to conventional RTM processes due to a more simple process chain.

ahead

Is there a guideline that can orient lightweight construction developers when choosing the best technology for their application?

Fenske

The material is too complex for a universal guideline, but a supplier market of companies is currently developing, who already have know-how in designing fiber composite components. With simulation software, many components can already be displayed and evaluated very well. Whoever gets active in this area for the first time is in good hands. We will, of course, be happy to establish contacts here.

ahead

Which technologies are currently in high demand at KraussMaffei?

Schmidhuber

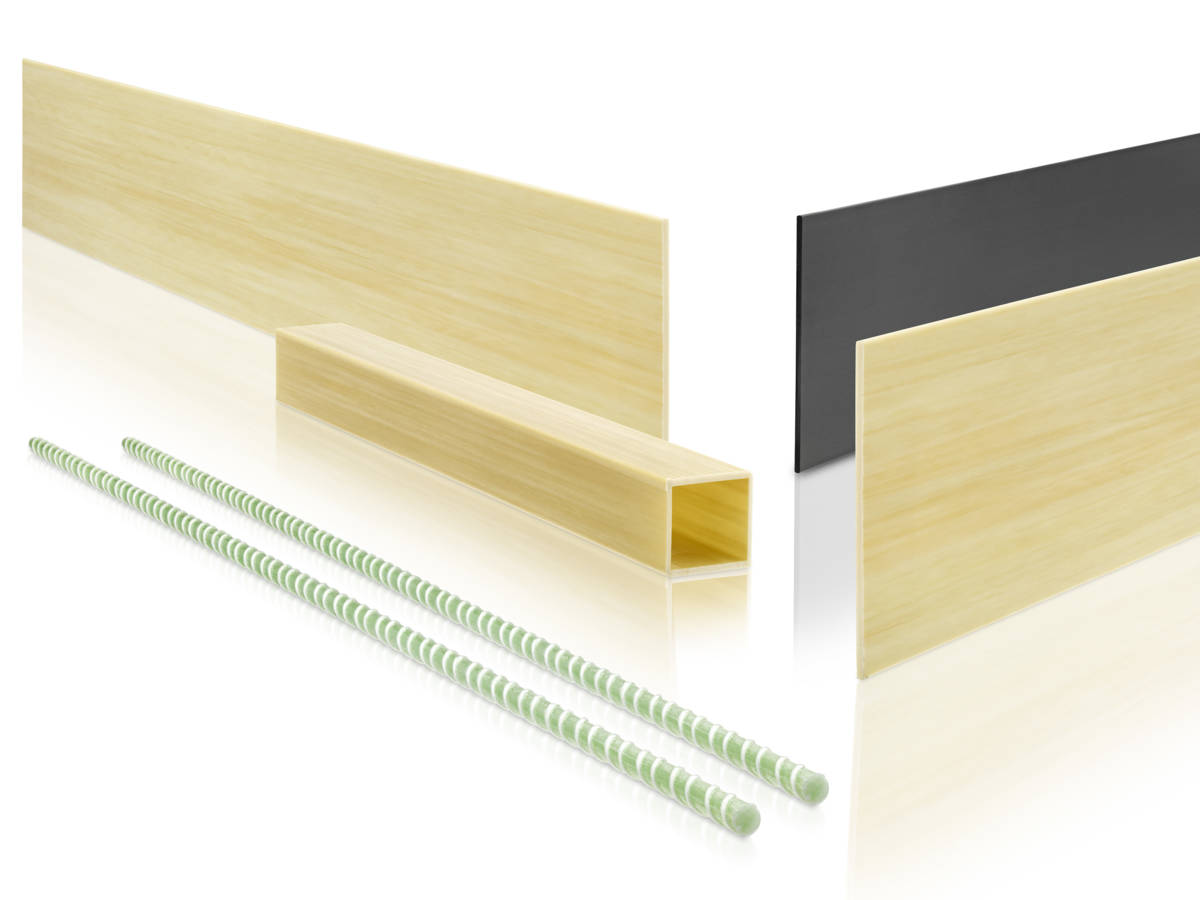

We are seeing a very high response in the market to our new pultrusion processes, although this particularly concerns the construction and wind power industries. At our Competence Forum in Munich this year (June 6-7), we will demonstrate pultrusion again, as well as another light-weight construction process, which is currently in preparation.

ahead

What do you think of newer developments that attempt to combine the advantages of duro and thermoplastics?

Fenske

There is already a lot possible here: Parts that were manufactured in RTM with a thermoplastic matrix (= T-RTM) can be further functionalized in the injection molding machine and can even be recycled. Or the FiberForm parts can be flow-coated with polyurethane (PUR) to improve the surface quality. Because our composite team is made up of experts in Reaction Process Machinery and injection molding, we always think across disciplines and find the best solution.

ahead

In which processes and materials will the bar be set even higher? And which have been more or less exhausted?

Schmidhuber

The matrix system reactivity in RTM processes will surely get faster. We are currently at about 90 to 150 seconds curing time. It was a lot longer a few years ago. High-pressure RTM is increasingly being replaced by the wet molding process. In the wet molding process, the procedures are simpler and, in contrast to the high-pressure RTM, no three-dimensional preforming is required. Production is thus more economical and the cycle times are shorter, so additional areas of application become possible.

ahead

What do you see for the future of lightweight construction?

Fenske

Composite technologies have huge potential and are impressive due to the combination of high component stiffness and light weight. That is very attractive for mobility as well as for construction. In both cases, with our solutions we are very well positioned along the entire process chain.

Contact

Stefan.Fenske@kraussmaffei.com

Contact

Sebastian.Schmidhuber@kraussmaffei.com