trendgineering

KraussMaffei goes formnext

| Julia Reich

precisionPrint and powerPrint at the leading trade show for additive manufacturing

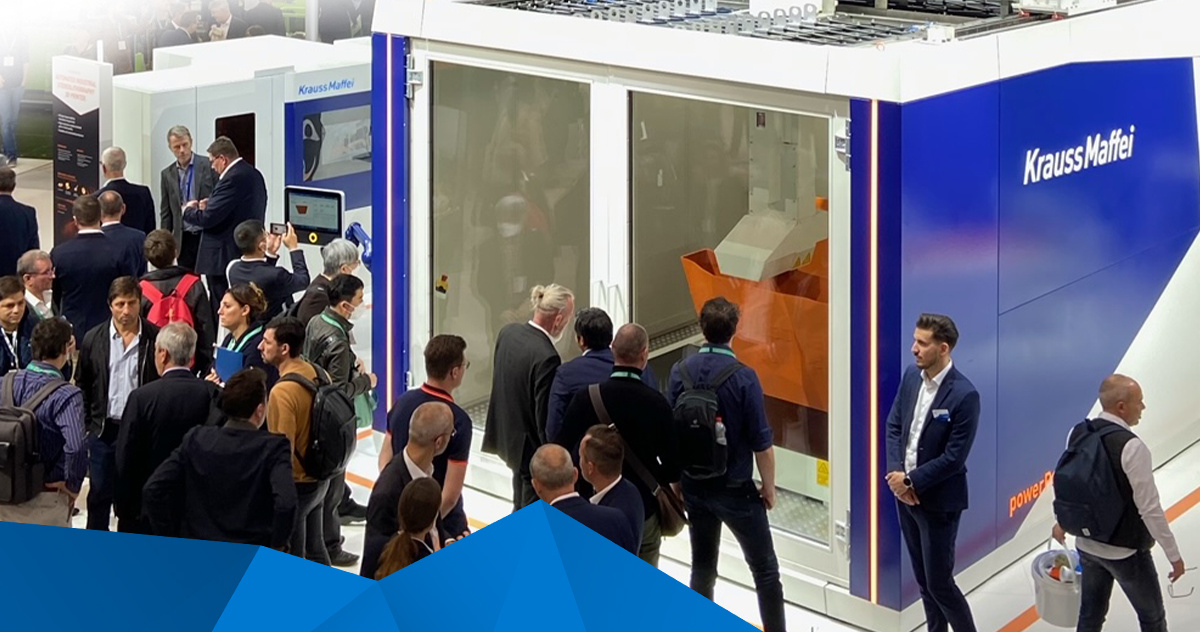

The next big appearance is just around the corner for the innovative 3D-printing division: From November 15-18, we will be showcasing our new additive manufacturing solutions for industrial production at formnext, the leading tradeshow for 3D printing, in Frankfurt (Hall 11.1, Booth F21)

Our many years of experience and in-depth know how from injection molding and extrusion technology are the foundation for our new, additive production solutions for series production. The fourth technology in our product portfolio – additive manufacturing or also known as 3D printing – opens up new opportunities in the industrial production of plastic products. And it does so regardless of the industry! Because our two new systems cover both the printing of large format products and the series production of individual parts.

powerPrint – the printer for large formats

The extruder-based system, which processes thermoplastic granules, can print components with volumes of up to 10 m³ to industrial standards. Favourable material costs, short makeready times and fast printing speeds enable efficient production and increase profitability thanks to the high output rate. The powerPrint is used above all in industries where customized solutions or fast production of near-net-shape components are required. In addition to mold making, such as in the foundry industry, furniture construction or utility infrastructure also benefit from the advantages of individual large-format-printing.

precisionPrint – series meets individuality

The high performance stereolithography printer enables series production of customized solutions at low cost. The sophisticated end-to-end system ensures that the surface quality as well as the detail resolution meets the highest requirements and makes the printing of small series possible. Especially in the medical industry, where for example hearing aids or braces can be printed individually, or in the electronics industry for connectors, but also in the field of sport and leisure, such as individual shoe soles, precisionPrint offers gread added value for the future thanks to its high precision.