sustainability

Live @Fakuma: The Turtle project

| Petra Rehmet

All-electric PX presents high-quality sandwich application with recyclate

Light, shiny and with a sustainable message - this is how the little blue turtle, which is produced on an all-electric PXZ 121-380-180 Multinject in a sandwich process, presents itself at Fakuma. The core consists of mechanically recycled PC/ABS, the high-quality outer layer of chemically recycled ABS. Numerous features of the PXZ 121, such as the new sandwich panel or the new APCplus function, which now also uses individual material parameters, make the multi-component process even more efficient and economical.

The increased use of recyclates has brought sandwich technology back into focus in multi-component technology and offers great potential.

Thanks to its precision, efficiency and flexibility, our all-electric PX series in the Multinject version as PXZ is ideally suited for this. We will be demonstrating this impressively here at Fakuma using the example of the Turtle project, which we have implemented with CONTURA MTC and other partners.Manuel von Varchmin

Director Sales IMM and Automation

The Turtle project combines a high-quality mold with a high-performance, all-electric injection molding machine from the PX series and the new LRXplus linear robot.

This combination brings clear economic benefits with an early ROI, while at the same time using valuable resources responsibly.

The core material of the durable turtle at Fakuma consists of mechanically recycled PC/ABS E-LOOP 5120MR from ELIX Polymers. However, a foamed or reinforced core made from recycled material is also conceivable and offers further potential for sustainable production.

The visible, high-quality outer skin is made of chemically recycled and processed ABS E-LOOP P2H-AT CR, which can be supplied in various colors.

Using resources sensibly: The turtle consists of a core made of mechanically recycled PC/ABS and a high-quality outer layer made of chemically recycled ABS.

Another sustainable aspect: the cold runner sprue is removed, shredded and fed directly back into the production process for the core material.

This is done with the new mini sprue mill from partner Getecha, which is being used for the first time. This also creates a closed material cycle.

More flexibility thanks to new sandwich platen

The all-electric PXZ 121 Multinject with a clamping force of 1200 kN impresses with its compact, space-saving Z-position with electric injection units. In addition, the attached, removable sandwich platen offers a high degree of flexibility in production.

This means that the PXZ 121 can be used as a single-component, two-component or sandwich machine - without any additional effort.

Another advantage: The simple switchover from skin to core melt flow ensures flexibility and high quality at the same time. On the one hand, the skin material can be added in order to seal the sprue point.

On the other hand, it is possible to switch between component A and B several times. This also allows marbling effects to be achieved for an individual design, for example.

Power meets sustainability: The all-electric PXZ 121 Multinject presents a high-quality sandwich application with a high proportion of recycled material at Fakuma.

Perfect surfaces – optimum cycle times

The right mold and the dynamic mold temperature control come from our partner CONTURA MTC. They are characterized by near-contour temperature control and thus optimize the entire production process.

Near-contour mold temperature control is particularly important in order to achieve the required high-quality surface of the turtle with economic cycle times.

Always a perfect fit - the new LRXplus linear robot

Part removal, separation from the sprue, separation into the grinder and depositing on the belt are the automation tasks of the new LRXplus linear robot, which is celebrating its premiere at Fakuma together with the MC7 control system.

The new LRXplus from KraussMaffei offers numerous new functions that make production even more flexible and economical.

Thanks to its compatible interfaces, the LRXplus can be combined with almost any system - whether with KraussMaffei injection molding machines, injection molding machines from other manufacturers or as a standalone solution for all other automation tasks.

Even more efficient – APCplus uses individual material characteristics

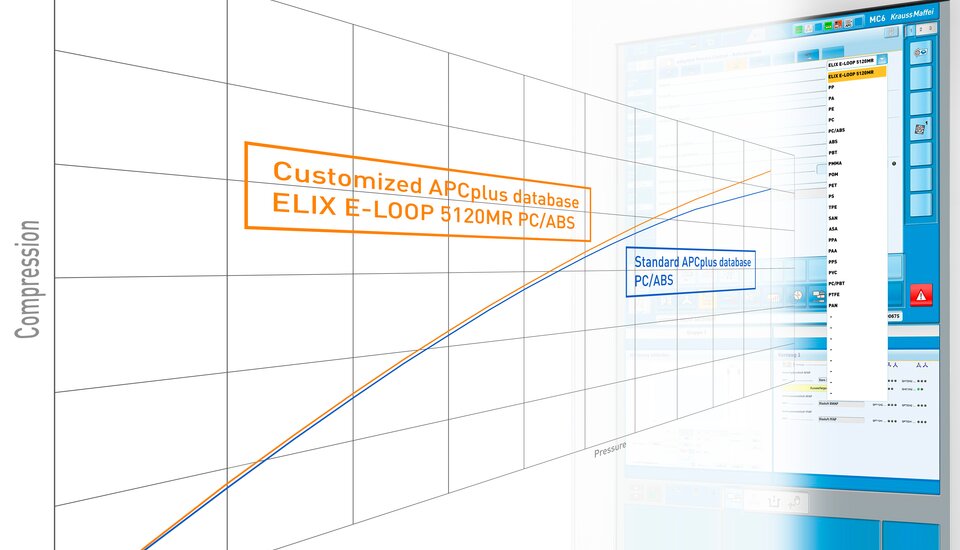

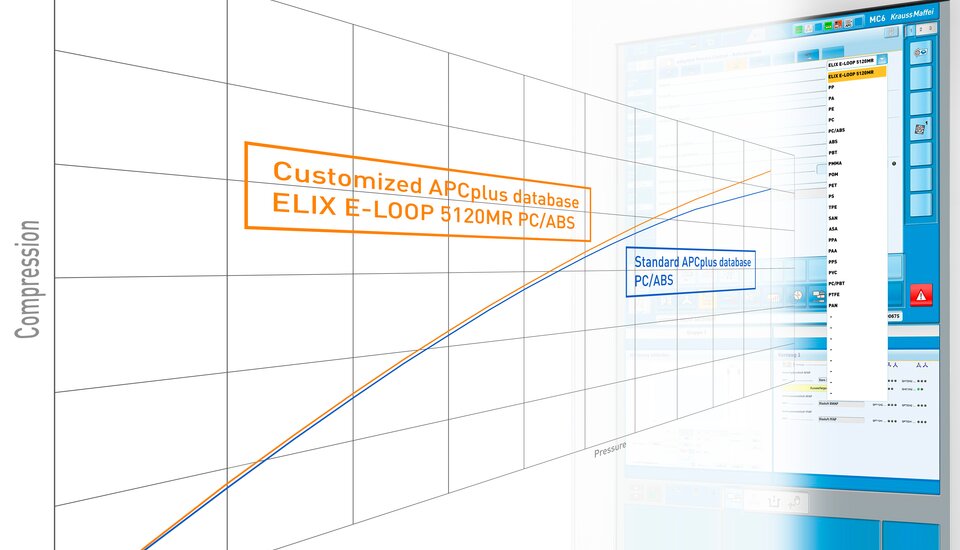

Thanks to its patent, APCplus (Adaptive Process Control) from KraussMaffei is the only machine function on the market that uses material-specific compression curves for process control.

The APCplus database contains all common material types that can be selected by customers for process control.

KraussMaffei is going one step further at Fakuma: all materials for use on the PXZ 121 Multinject come from ELIX Polymers, which, like KraussMaffei, is also a Sinochem Group company.

With the specific material parameters from ELIX Polymers, which are integrated into the APCplus database, the machine function is precisely adjusted to the material being processed, making the injection molding process even more precise and efficient overall.

Even more efficient injection molding: The patented APCplus machine function now also records individual material-specific characteristic values – at Fakuma from partner ELIX Polymers.

Why a turtle?

Turtles have always been a symbol of wisdom, longevity and wealth. At the same time, the plastics industry faces the challenge of developing sustainable solutions to prevent the destruction of these reptiles’ habitats.

Therefore innovative processes and materials are needed to ensure a balance between industrial progress and the preservation of natural habitats.

KraussMaffei's Turtle project together with its partner CONTURA MTC sends a strong signal for a sustainable future and impressively demonstrates at Fakuma 2024 what innovative partnerships combined with technological excellence can achieve.

The all-electric PXZ 121 Multinject, the new LRXplus linear robot and the new APCplus function provide impressive proof of recycling and resource conservation while maintaining quality and cost-effectiveness in plastics processing.

Other partners at the trade fair exhibit are A&E Produktionstechnik, CONSTAB Polyolefines Addtives, CycleTemp, Formconsult Werkzeugbau, Konstruktionsbüro Hein, Motan, Jurke Engineering, SimpaTec Simulation & Technology Consulting, Reichle Technologiezentrum and technotrans solutions.