Insights

Major advancement in pultrusion

| Petra Rehmet

FSK Innovation Award 2017

KraussMaffei, together with Covestro and the Institute of Plastics Processing at RWTH Aachen University, was the recipient of the 2017 Innovation Award for polyurethanes. The Specialist Association of Foamed Plastics and Polyurethanes (FSK) elected to honor the partners’ achievements in promoting the wider industrial use of pultrusion with polyurethane resins.

For the award in the category “Technology – Processing and Chemistry,” the panel of judges commended the increased cost-efficiency of the method for processors and the partnering approach to the project. The award ceremony was held at the International FSK Specialist Conference Polyurethane 2017 in Gurten, Austria.

Award for pultrusion

Wolfgang Hinz from KraussMaffei (left) and Benedikt Kilian from Covestro (second from left) are proud winners of the 2017 FSK Innovation Award for polyurethanes (Albrecht Manderscheid, second from right, and Dr. Alexander Strietholt, right)

Tremendous potential

Pultruded composite sections have already proven successful in thermally insulating window frames, battery trays in electric cars and in reinforcing rotor blades for wind turbines. The process offers tremendous potential for the continuous manufacturing of composite sections, but more widespread use was prevented until now by the inadequate degree of industrialization. In close cooperation, the three partners enhanced the chemistry, technology and process to significantly increase productivity as well as process and product quality. Processors can now cut costs by up to 24 percent compared to the previous method.

Flexible turnkey systems with high automation

The new iPul machines from KraussMaffei are the first turnkey systems to incorporate system, process and die technology all from a single supplier. Critical processing parameters, such as output rate and haul-off rate, are controlled centrally. In the new systems, the fibers are no longer impregnated in an open process, but rather by a metering machine in a closed injection chamber. Apart from eliminating odor problems for a pultruder’s employees, the new technology supports precision temperature management during curing and thus increases production speeds. The systems are sensor-assisted and highly automated. Another advantage of the iPul machines is their extensive flexibility and precision. Thanks to the injection chamber and metering device with newly engineered mixing head, a wide variety of resins can now be processed, including highly reactive polyurethane systems. The matrix material is injected at low pressure to additionally cut costs.

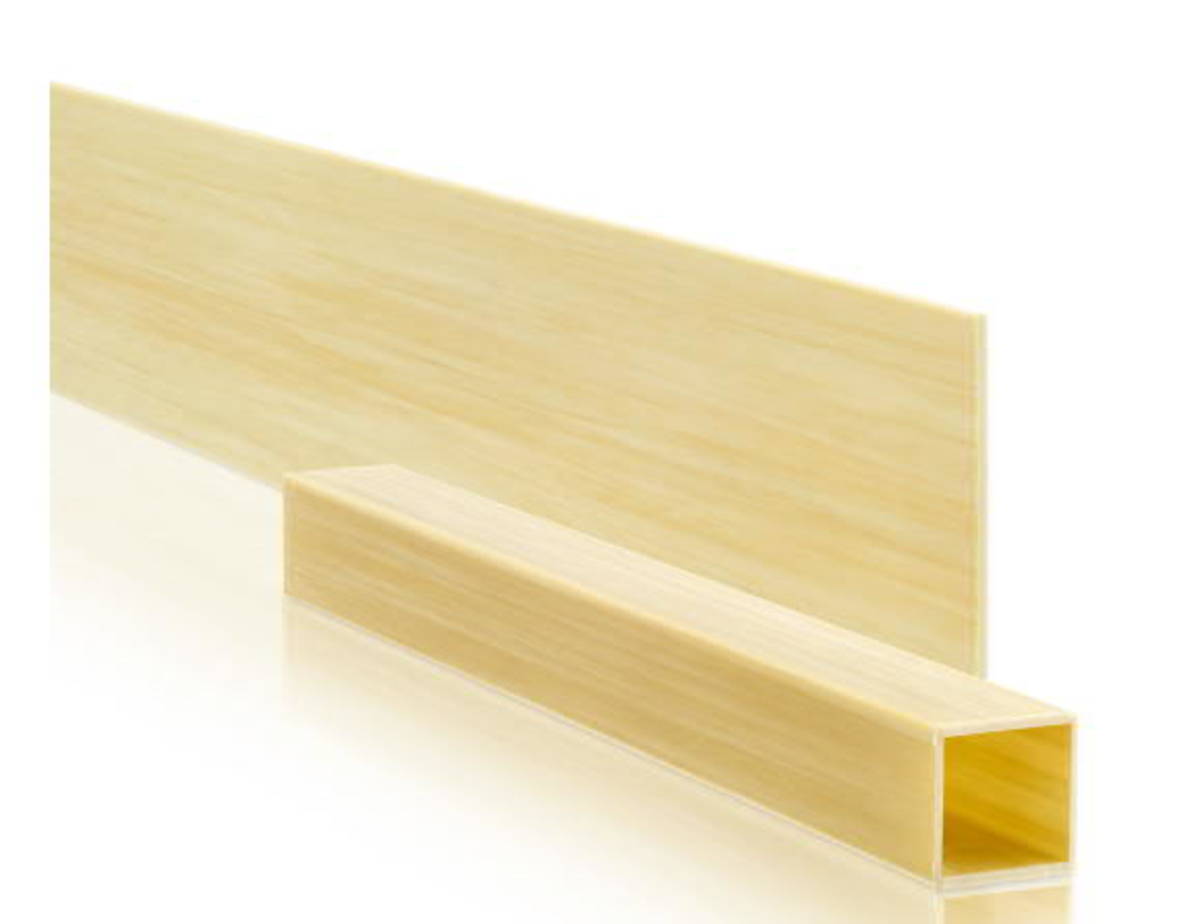

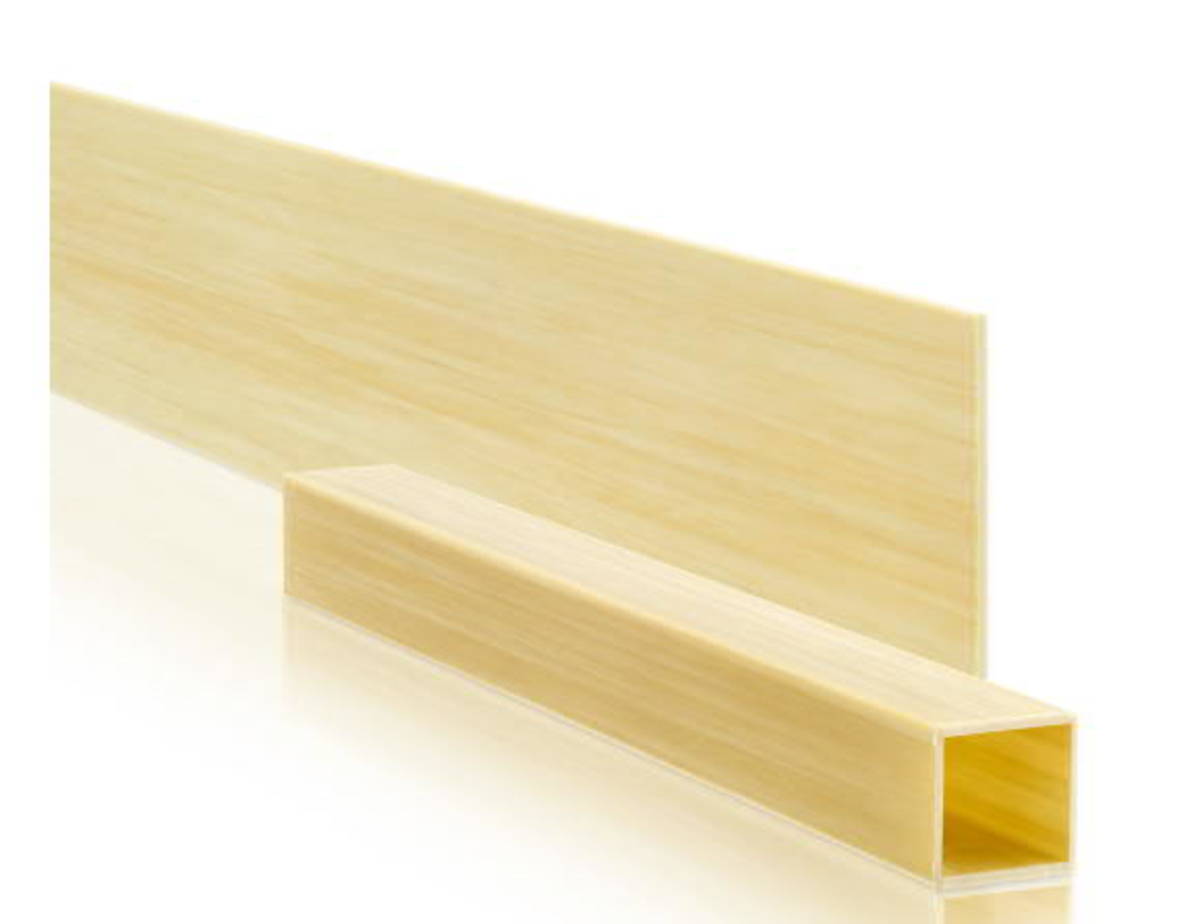

Benefits of pultuded profiles

- Significant weight savings

- Low heat conductivity

- Simplied use and low transport costs

- Resistant to material fatigue

- Resistant to chemicals and corrosion

The polyurethane advantage

Polyurethane resins offer significant advantages over established pultrusion materials, such as epoxy, unsaturated polyester and vinyl ester resins. Their low viscosity, good fiber wetting and high reactivity support faster processing speeds than epoxies, which reduces manufacturing costs. Another advantage is their considerable flexibility: The reaction time and viscosity of polyurethane resins can be varied widely, permitting the reproduction of even very thin component geometries. Covestro markets the polyurethane systems Baydur® PUL and Desmocomp® for pultrusion. The former are liquid, two-component systems for fabricating highly durable sections that display outstanding thermal insulation properties, among other things. They therefore are perfectly suited for use in insulating window frames. Desmocomp® displays not only good mechanical properties, but also excellent UV and weathering resistance, making it the product of choice for outdoor applications. The aliphatic system won a JEC Innovation Award at JEC World Composites trade show 2017.

How pultrusion works

In pultrusion, glass, carbon or other fibers are fed continuously from rovings into an injection chamber, where they are impregnated with a liquid, thermoset resin system. The fiber composite cures on exposure to heat in a die. The hardened section is pulled continuously in the process, hence its name. After cooling, the strand is trimmed by an integrated saw. The resulting, straight sections display low weight, paired with very high strength and stiffness in the fiber direction.

Covestro and the Institute of Plastics Processing (IKV) at RWTH Aachen University are cooperating closely on pultrusion process development using polyurethanes. The IKV with its long-term experience is supporting Covestro in the fields of polyurethane processing and pultrusion with reactive resin systems in case of development issues regarding pultrusion processes. The FSK has been sponsoring the Innovation Award every year since 1998 in recognition of outstanding ideas, products and processes in the categories Design, Technology and Process and Chemical Engineering.

Contact

Wolfgang.Hinz@kraussmaffei.com