Processes & Products

New mold carrier for the TechCentre Lightweight Construction

| Petra Rehmet

Flexible design increases efficiency

KraussMaffei expands its TechCenter with a new shuttle mold carrier and its competence in the area of fiber-reinforced lightweight construction. The new MX mold carrier with a clamping force of 4,000 kN has a flexible design and can be used for different processes.

This includes both the LFI process (Long Fiber Injection) and the SCS process (Structural Component Spraying) with spraying applications. Also surface technologies such as R-RIM (Reinforced Reaction Injection Molding) with polyurethane are possible.

From idea to series production

"The market for fiber-reinforced composites continues to develop very dynamically. We support our customers sustainably from the idea to the serial production. That's why we are continuously modernizing and expanding our lightweight construction TechCenter and offering our customers optimal conditions for developing and testing new production-ready technologies and automation tasks", explains Sebastian Schmidhuber, Head of Development of Reaction Process Machinery at KraussMaffei.

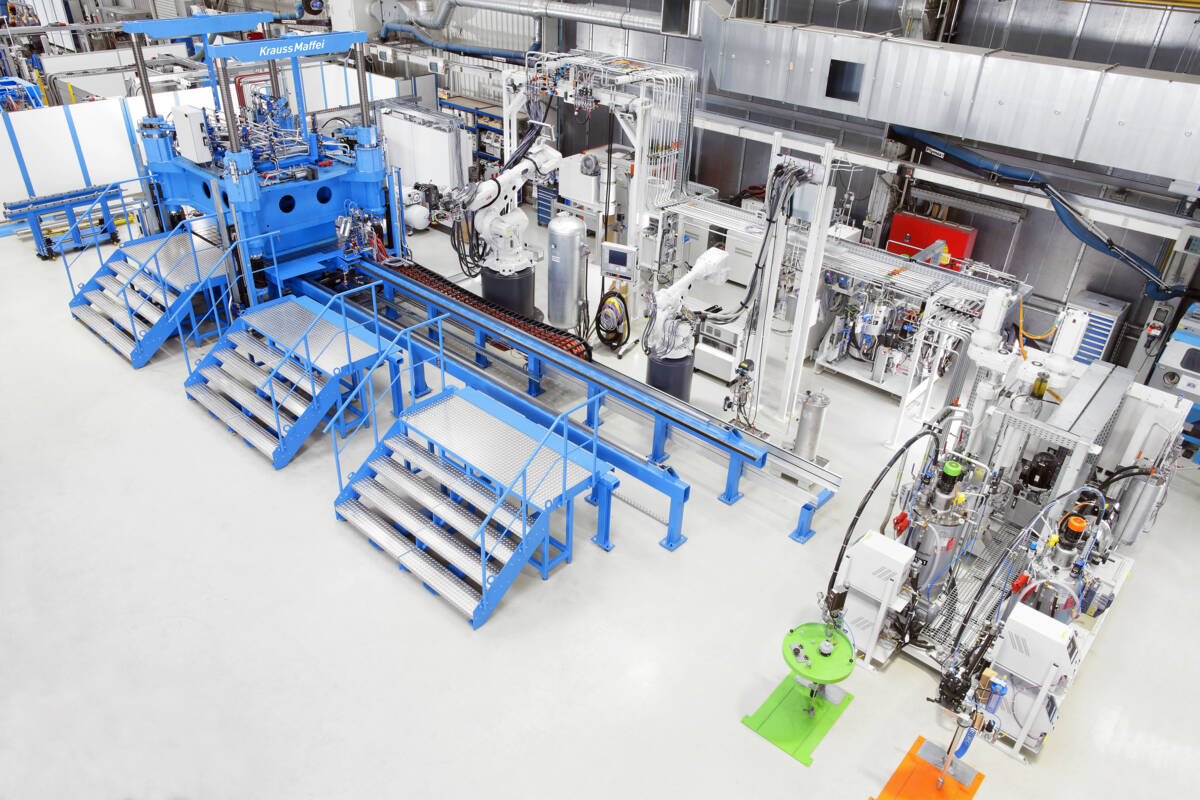

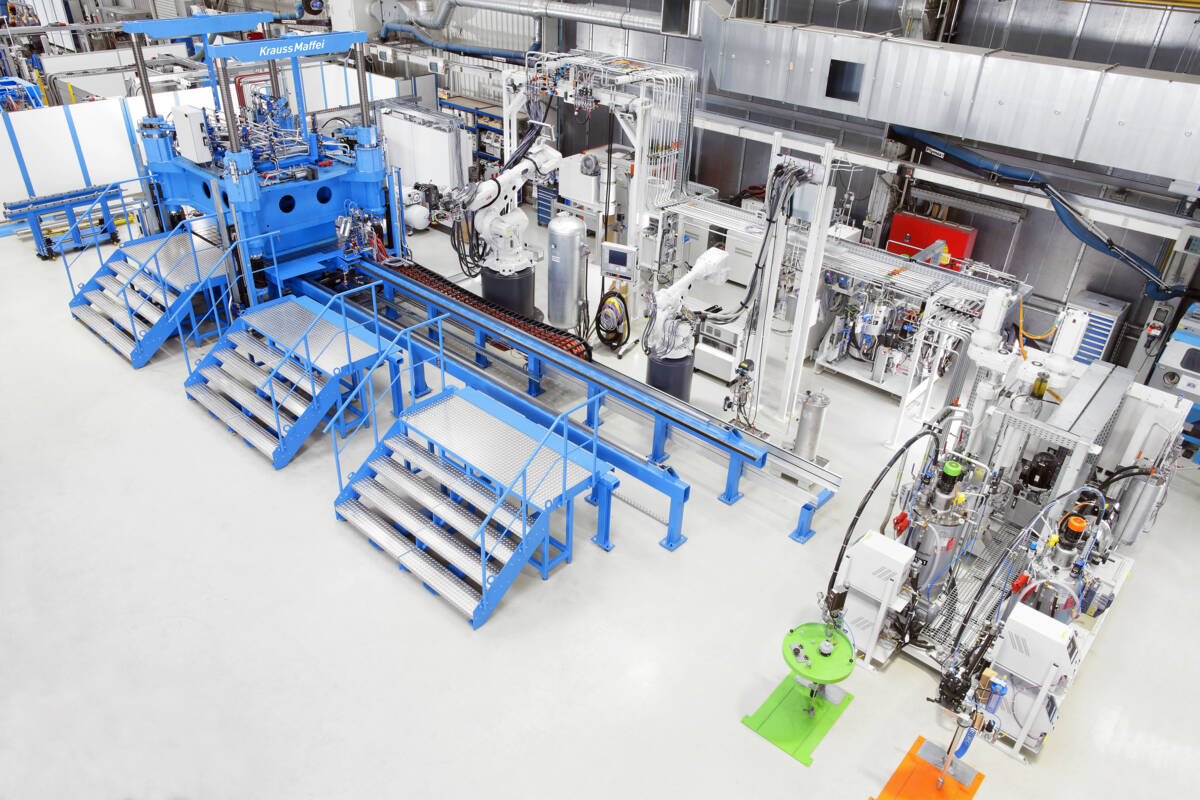

The new shuttle mold carrier is part of a complete system, which has a separate cab and robot for the LFI and SCS spraying processes. A total of five different mixing heads are available for the different tests and automation tasks. A special shuttle carrier is used to quickly transport the bottom mold between the machining stations of the bottom mold. As a result, the foam discharge, for example, can occur in the bottom mold outside of the clamping unit. Another distinguishing feature of the series is the tilting movement of the upper and lower mold fixing platens. "We offer our customers the necessary flexibility and can quickly change over to the respective automation task. And this is possible throughout the entire process chain", adds Sebastian Schmidhuber.

Can be used flexibly for large-format visible components or new spraying processes:

The new shuttle mold carrier in the KraussMaffei lightweight construction TechCenter in Munich for LFI and SCS applications

Long Fiber Injection (LFI)

- Wide range of applications

- Series from a small trim part for a car interior to a large structural component

- PUR process where mold cavity pressures are < 10 bar

- High-strength sandwich element with a honeycomb structure as the core layer

Structural Component Spraying (SCS)

- Further development of LFI honeycomb technology

- Reduces the thickness and the weight of the top layers for optimizing lightweight construction

- Layers composed of fiber mats and honeycomb cores are sprayed with unreinforced PUR, inserted into a mold, and pressed into shape

Unique lightweight construction TechCenter

The KraussMaffei TechCenter in Munich is leading-edge. On over 4,000 m² more than 25 systems from injection molding, reaction processing machinery and extrusion technology are available for internal tests and customers to optimize their processes in practice or test prototypes. KraussMaffei is at the forefront of developments, particularly in the area of fiber-reinforced lightweight construction. In terms of Reaction Process Machinery this includes, for example, the different RTM processes, Pultrusion or the LFI process, as well as the thermoplastic FiberForm process in Injection Molding Machinery.

Contact

sebastian.schmidhuber@kraussmaffei.com