trendgineering

Perfection in 40 seconds

| Rebecca Böhm

How KraussMaffei Viersen automates the assembly of door interior trim for premium vehicles

Two door interior panels assembled in just 40 seconds – fully automatically. What sounds like an ambitious goal has long been reality at KraussMaffei's Viersen site. For Tier 1 supplier Yanfeng, a leading global provider of interior solutions, the team led by plant manager Marcel Joppen has developed a highly automated assembly line that combines complex processes with impressive speed and precision.

Efficiency meets precision

In plastics processing, the goal is clear: "The component should come out of the machine ready to use." But where technical requirements necessitate downstream processing steps, one thing counts above all else - efficiency.

This is exactly where KraussMaffei Viersen comes in: With tailor-made automation solutions, the team ensures that even complex assembly steps are seamlessly integrated into the production process.

Intelligent assembly line for premium components

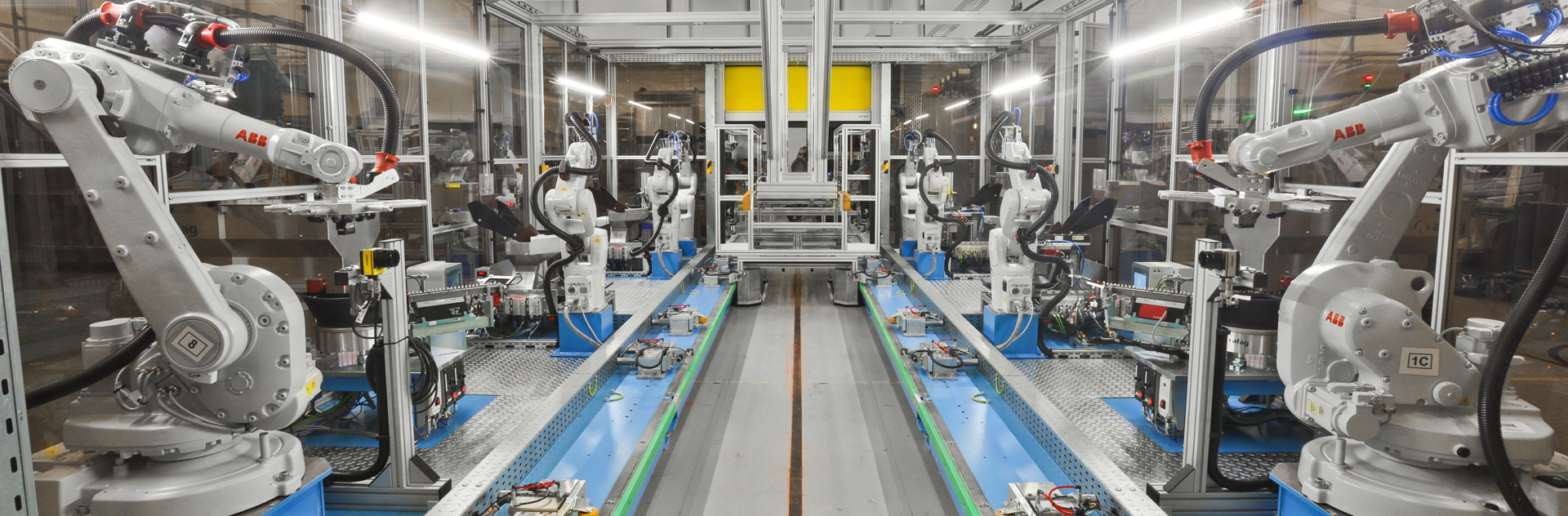

A manufacturing concept was developed for Yanfeng that guides the door panel-i.e., the base carrier of the door interior trim-through three automated stations. Components such as the card pocket, recessed handle, and armrest are assembled there.

Two door panels are placed simultaneously on a self-propelled load carrier, which guides them past robots positioned on the left and right.

In our Trimming Technology Center, we can do almost everything that needs to be done after the actual plastic part has been manufactured.Marcel Joppen

Plant manager in Viersen

A barcode scanner recognizes the door variant, and a camera checks the exact position of the components. This ensures that the five to seven add-on parts are positioned with millimeter precision.

The 18 screws per door are removed from a dispenser by ABB robots and inserted in just four seconds - a process that cannot be performed pneumatically due to the geometry of the screws and is therefore particularly challenging.

Clips with rubber seals: precision every second

The clips are also attached fully automatically. An ABB robot with a vacuum gripper picks up nine clips in just 13 seconds. A laser sensor measures the clip positions in depth, as the door panels can sit differently on the frame.

Each clip is set in just 1.4 seconds - including camera and laser measurement, this results in a cycle time of 29 seconds. The camera system itself operates at an impressive speed: it takes just 350 milliseconds to capture images, evaluate them, and calculate translation and rotation.

The entire assembly line thus achieves a cycle time of only 40 seconds - for two complete door interior panels.

Trimming Technology Center: Tailor-made solutions since 2005

The Trimming Technology Center in Viersen is at the heart of this innovation. Since 2005, automation solutions for the post-processing of plastic parts have been developed here - from punching and laser cutting to ultrasonic welding.

Special processes such as scoring, in which airbag predetermined breaking points are specifically reduced, are also part of the portfolio. With 75 employees and a clear focus on customized customer solutions, the center is a strategic building block for KraussMaffei - not only in the automotive industry, but increasingly also in medical technology.

Partnership on equal terms

The collaboration with Yanfeng shows how technological excellence and mutual trust lead to sustainable success.

KraussMaffei is an important strategic partner for us. Together, we are doing everything we can to optimally meet the high demands of our OEM customers. The plant in Namestovo is currently in a dynamic development phase with great potential for new projects. In this context, we rely on the extraordinary support and trusting cooperation with KraussMaffei to successfully achieve all the milestones defined by the customer.Martin Kerestesi

Plant manager of Yanfeng International Automotive Technology Slovakia in Namestovo