Trendgineering

Plug & Produce concept for silicone

| Petra Rehmet

KraussMaffei makes it easy to get started in LSR processing

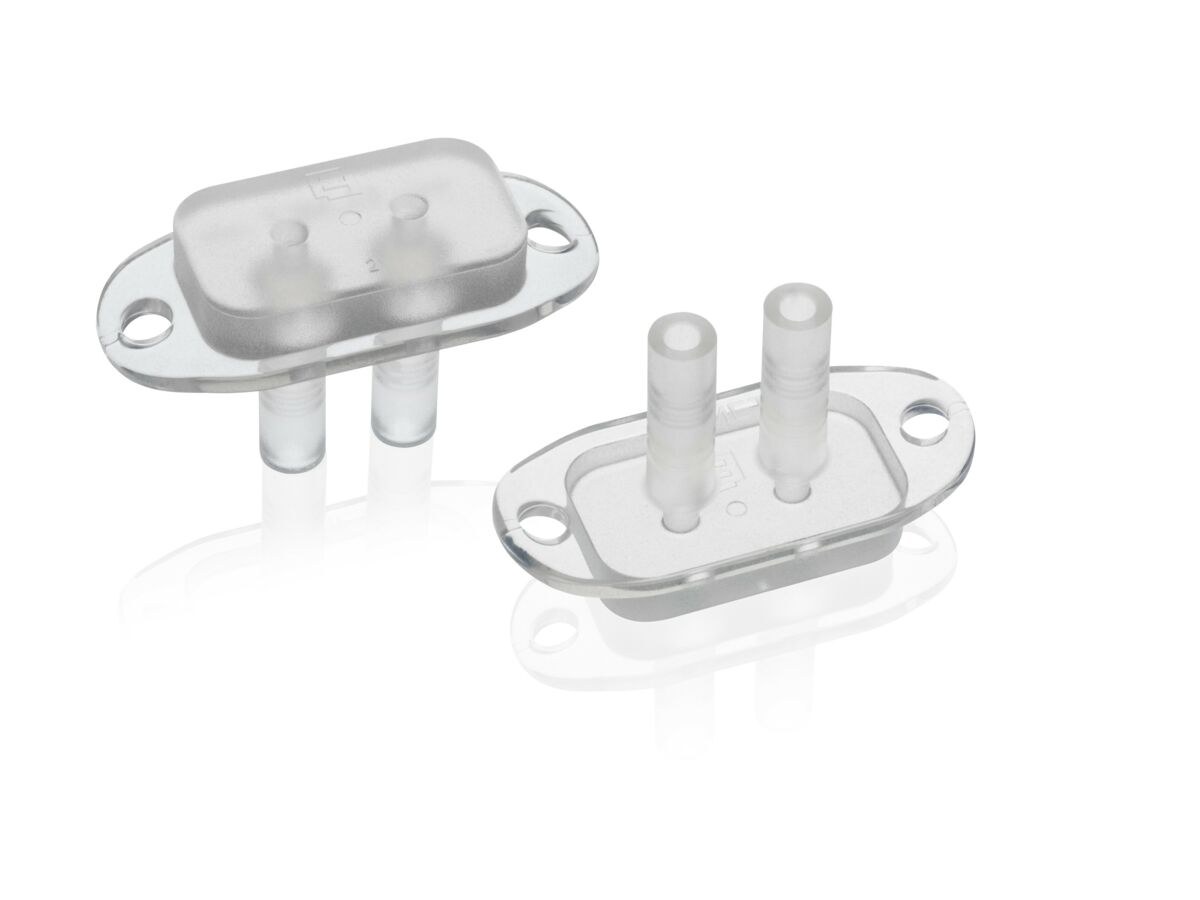

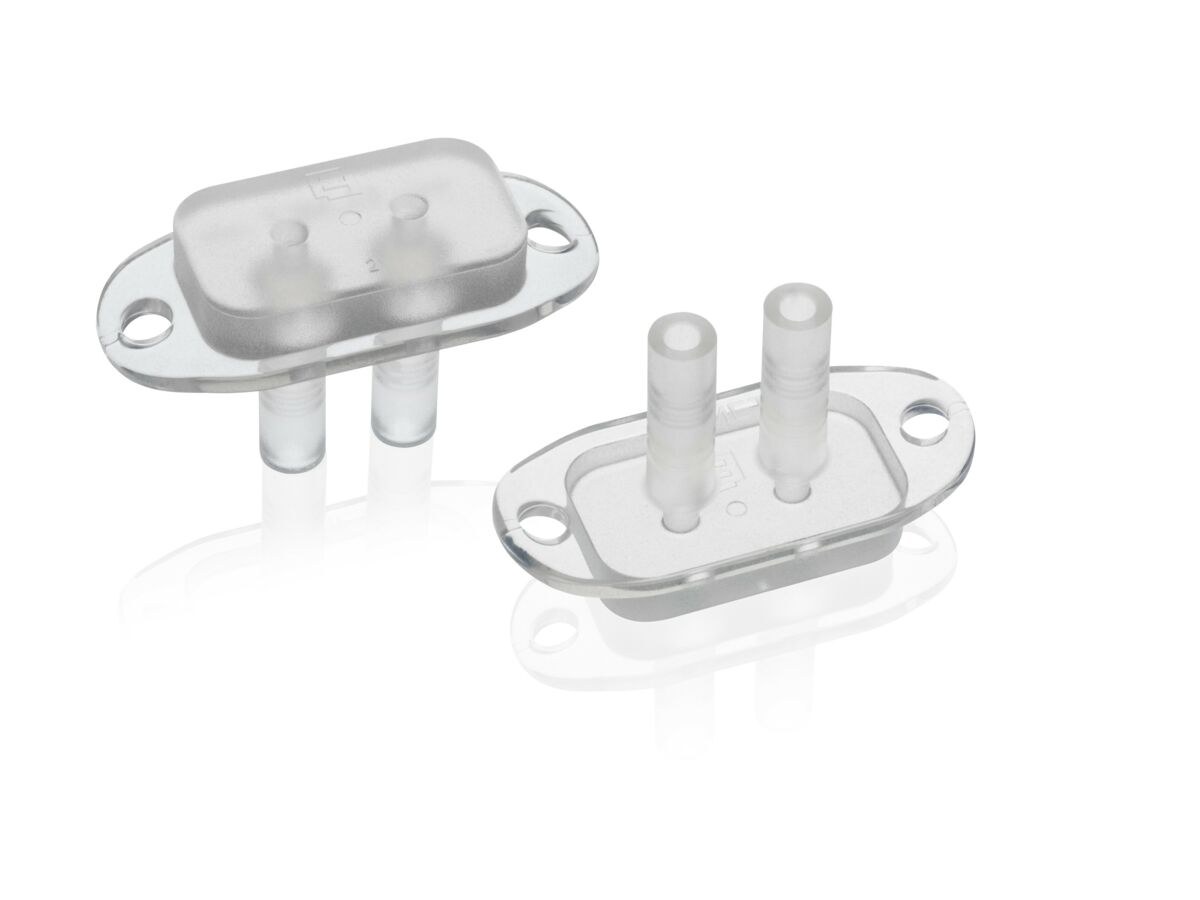

Set up a system and start producing right away—with a new process and customers from the medical sector with extremely high standards. Is this possible? By obtaining expert support when getting started in the silicone world, it is indeed. KraussMaffei demonstrates this with the nasal cannula.

Admittedly, many aspects of reactive silicone processing are different from the familiar thermoplastic area. Many experienced injection molders are hesitant to jump to the new technology. However, silicones—whether liquid (LSR) or solid (HTV)—are opening up new application areas all the time thanks to their physical properties. They offer great opportunities for growth. And with a system partner who is up to the task, such as KraussMaffei, the Plug & Produce concept can be applied to this material as well.

For example, an all-electric PX 50-180 with a clamping force of 500 kN can produce four nasal cannulae in one shot. This is at a shot weight of 6.7 g in a cycle time of 24 s. For this purpose, initially, two barrels supply the fully mixed component A (consisting of base polymer, platinum catalyst, and additives) and the component B (consisting of base polymer, curing agent and inhibitor) and joined together in the mixing unit. These and the downline plasticizing unit must be cooled (approximately 20 °C) to prevent a premature reaction. In exchange, the temperature in the mold can then reach approximately 180 °C and the curing begins.

Master of reactive silicone processing

four nasal ventilation units are created in one shot on a fully electric PX 50-180

Uniform shot weight with APC plus

Unlike thermoplastics, silicone does not shrink in the cavity—rather, it expands. Therefore, the shot weight cannot be corrected by holding pressure. It must be correct from the beginning. KraussMaffei ensures this using a variety of proprietary developments. For example, the servoelectric system of the PX series controls the movements of the screws and the screw shaft. The low mass enables high-precision control of the screw position.

In addition, the APC plus (Adaptive Process Control) machine function measures the viscosity of the melt and controls the filling quantity individually in the same shot. This is particularly important for batch fluctuations. However, APC plus also offers a clear advantage during a restart after a machine standstill by minimizing the number of cycles until the required shot weight consistency is reached again. Even the first shot can be run in fully automated fashion. This, in turn, saves time and money.

LSR has a wide variety of features

The low viscosity of silicone makes it possible to replicate the desired shape with very high accuracy, even for the finest structures. However, this places stringent requirements on the leak-tightness of machine and mold. Deviations must be less than five micrometers to prevent leaks. Often times, a vacuum is applied to the mold.

resistant and highly flexible

LSR forms the ideal nasal ventilation unit

Producers who meet these requirements benefit from a product that resists aging and chemicals, is highly flexible, flame-resistant and free of plasticizers, in addition to being resistant to aging and bacteria. In particular, the medical and automotive industry are becoming increasingly interested in this. Another reason is that the manufacturing can be made just as compact and cost-optimized as for thermoplastics. For the nasal cannula, the entire automation is integrated into the safety cell, where an SPX 10 servo-electric sprue picker with enhanced functions removes the parts, separates them and deposits them. The compact system solution needs a footprint of less than 7 m² and has CE certification. This saves additional installation area, which means a cost advantage, specifically for cleanroom applications.

With a complete package from KraussMaffei, silicone processing is no longer the exclusive territory of specialists. New entrants to the market also have the opportunity to take part in an exciting growth market.

Advantages of liquid silicone (LSR) in the medical area

- Biocompatible

- Bacterially resistant

- Can be sterilized because it is temperature-resistant

- Permanently elastic

- Free of plasticizers

- Long service life

contact

cordula.wieland@kraussmaffei.com