Trendgineering

Sophisticated injection molding processes in record time

| Petra Rehmet

The new generation of LRX linear robots

The new generation of KraussMaffei LRX linear robots grows with your requirements. Three key benefits for plastics processors are the wide selection of axis lengths and wrist axes, optimal integration of peripherals and great flexibility in complex, challenging injection molding processes.

The EcoMode function enables energy savings of up to 20 percent. The new, larger handheld pendant provides more information and easier control and operation. Like its predecessor, the new generation features outstanding precision and cost-effectiveness. How? The super-fast acceleration means shorter cycle times—to give just one example.

"In developing the LRX linear robot, we made it a point to incorporate our customers' requirements. This includes, for example, a wide range of options and the ability to switch production from one application to the other quickly and efficiently."Dr Volker Nilles, Executive Vice President New Machines KraussMaffei

Thanks to the modular system, KraussMaffei provides their customers with custom-tailored system solutions. Later upgrades and retrofits are possible as well. The new linear robot product line also includes customized gripper solutions tailored optimally to the mold and the component. All components are integrated centrally into the MC6 control system and are easy and intuitive to operate. This is a boost for operating convenience.

Saving resources – Energy savings of up to 20 percent

Energy efficiency and resource-conserving production are becoming more important all the time. As a result, KraussMaffei is now offering the EcoMode function as a standard feature for all linear robots in the LRX series. Eco-Mode ensures that the operating speed of the robot is adapted to the cycle of the injection molding machine. This reduces waiting times but has no influence on the cycle time. This, in turn, relieves the load on the mechanical system and the drive train and provides energy savings of up to 20 percent.

More potential for conserving resources is offered by the optional air-saving valves for generating a vacuum with integrated air-saving control. This interrupts vacuum generation as soon as the component is gripped securely and the configured vacuum value is reached. When the threshold value is undershot, vacuum generation is activated again. Compared to conventional vacuum valves, this function uses far less compressed air. This, in turn, saves energy and money.

More information and operating convenience

The development of the new handheld pendant was focused on providing the operator with more information and greater convenience during operation. The new capacitive multitouch panel has a diagonal screen size of 10.1". Thanks to the high resolution of 800 x 1280 pixels and the pressure-sensitive touchscreen, the operator now has a clearly arranged view of information that he or she can respond to quickly.

Agile and lightweight

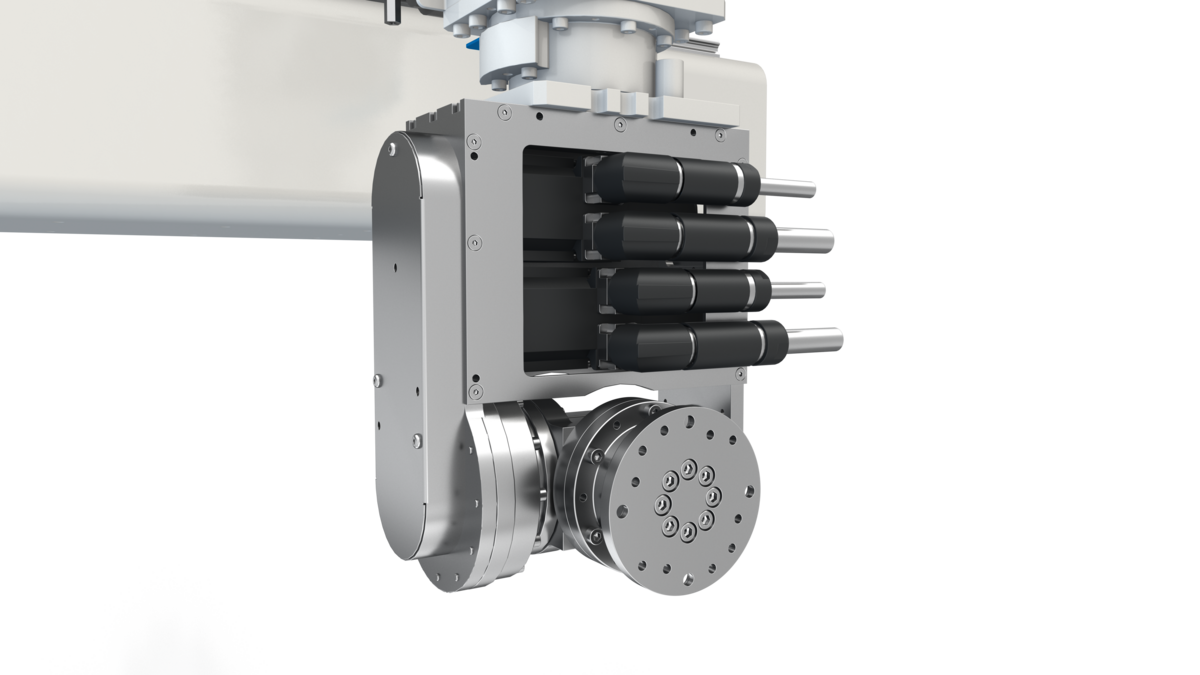

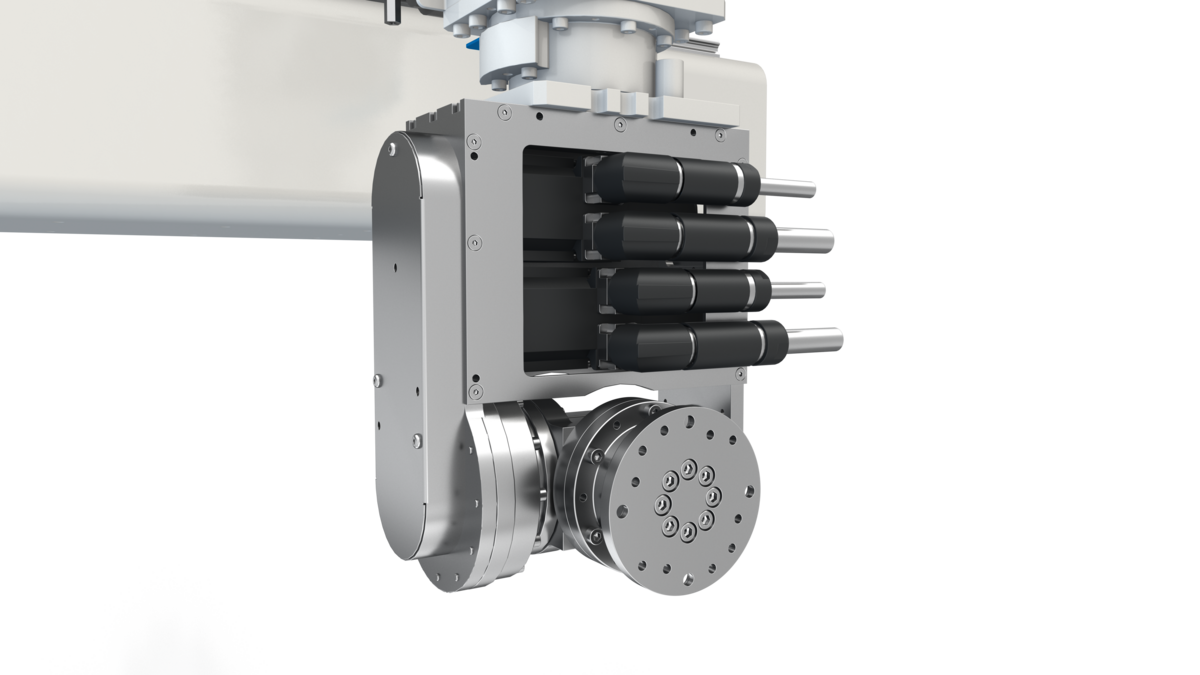

The wide selection of pneumatic and servo wrist axes ensures high robot precision in parts handling

Boosted pneumatics and vacuum for greater flexibility

The number of configurable circuits offered in standard models has been increased from the current 4/4 to 8/8. All the latest-generation LRX linear robots now offer the ability to implement up to 8 vacuum and 8 pneumatic circuits. In addition, the media portal on the Y-axis has been optimized to make gripper changes even faster and easier. The bottom line: greater flexibility for plastics processors, particularly for complex and challenging injection molding processes.

Shorter cycle times and greater process reliability

The outstanding features of the linear robots in the LRX/LRX-S series from KraussMaffei include particularly fast acceleration, which enables short cycle times and high productivity. This applies to the new generation as well. Furthermore, the LRX linear robots have excellent precision for component insertion—another winning feature

"The repeatability is less than 0.1 mm. Our in-house measurements have obtained yielded values of 1.8 mm from other manufacturers. We are thus offering our customers significant added value."Dr. Volker Nilles, Executive Vice President New Machines KraussMaffei.

These values shorten the mold opening time for component insertion and demolding and enable faster production in a safe process. The bottom line here as well: shorter cycle times and thus greater productivity in injection molding production.

Fast, precise, and modular – the new generation of KraussMaffei LRX linear robots provide plastics processors even greater flexibility in complex, challenging injection molding processes with the usual high precision, speed and repeatability. The new generation is offered in combination with injection molding machines from KraussMaffei or other manufacturers as well as a standalone unit.