trendgineering

5 questions for... Magdalena Schwangler and Michael Helneder

| Julia Reich

The product managers talk about the special system features

Magdalena Schwangler and Michael Helneder talk about the differences between the two Additive Manufacturing products powerPrint and precisionPrint. They also talk about why the systems are not only suitable for printing prototypes.

Magdalena Schwangler and Michael Helneder

The experts for the powerPrint and precisionPrint.

AHEAD

The two Additive Manufacturing systems are very different. Let’s start with the powerPrint: What makes the system special?

Magdalena Schwangler

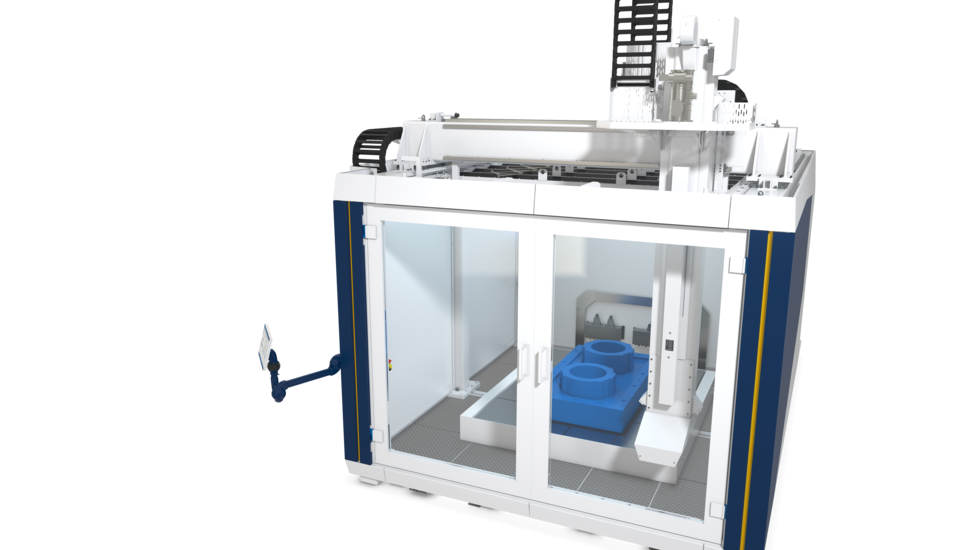

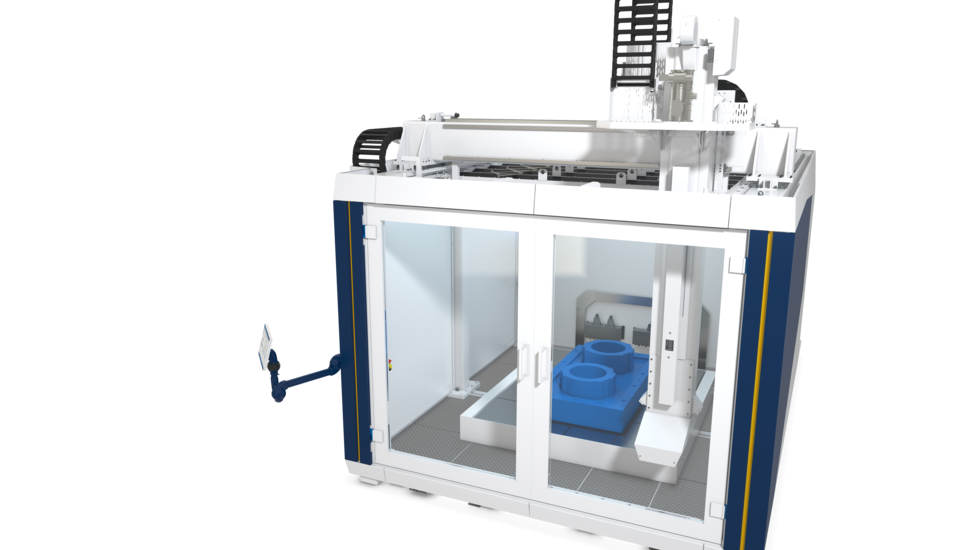

The powerPrint is a granulate-based large scale 3D printer – it prints large components to industrial standards at low unit costs. The special feature of this system is the thermally insulated, closed build chamber: its design ensures high process stability, ensuring high-quality printing with a high variation of materials. The precisionPrint, on the other hand, is based on a completely different mode of operation.

AHEAD

What is so special about precisionPrint? What are the differences to powerPrint?

Michael Helneder

Unlike the powerPrint, the precisionPrint prints much smaller objects. The stereolithography 3D printer is particularly geared towards resin-based industrial series production of precise printed components. The unique system design with its magazine towers enables an automated process chain. In addition, the precisionPrint uses top-down laser technology to achieve extremely high speeds.

AHEAD

Interesting – and when is which system worthwhile?

Michael Helneder

The powerPrint is worthwhile when printing large scale components (up to 10m3) with low batch sizes, especially if the original manufacturing method is time-consuming or cost-intensive. It´s also worthwile when different components are to be printed simultaneously, i.e. during one print job. The precisionPrint, on the other hand, is worthwhile for individual series production with very high quantities when complex components with the highest precision are required.

AHEAD

Sounds like both systems are suitable for many applications?

Magdalena Schwangler

Yes, almost every industry, in which injection molding in particular is used, can benefit from the advantages of our industrial systems in individual phases of the product life cycle.

Almost every industry, in which injection molding in particular is used, can benefit from the advantages of our industrial systems in individual phases of the product life cycle.Magdalena Schwangler

Product Owner Additive Manufacturing

AHEAD

So it’s not just about printing prototypes. For which industry is Additive Manufacturing a useful manufacturing process?

Magdalena Schwangler

With powerPrint, many industries that work with large components, such as foundries or mold and model making, benefit. The fast and cost-effective production or finished components, which no longer require manual steps – as is the case with conventional manufacturing methods – increases their productivity. The precisionPrint finds its application in all areas where individual small components are required. For example, in the medical sector with hearing aids or in the Electric & Electronics sector with a wide variety of connector housings.