sustainability

Circular Economy live @NPE

| Petra Rehmet

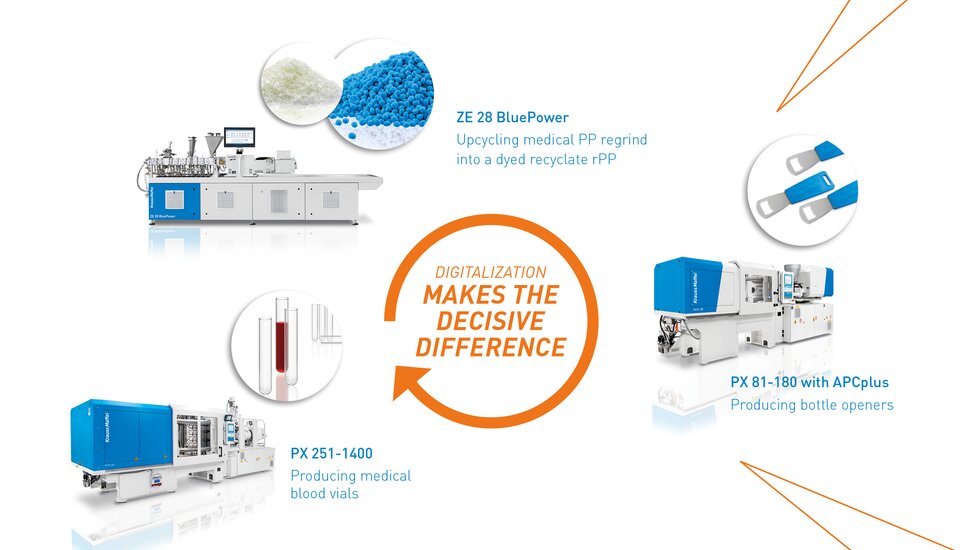

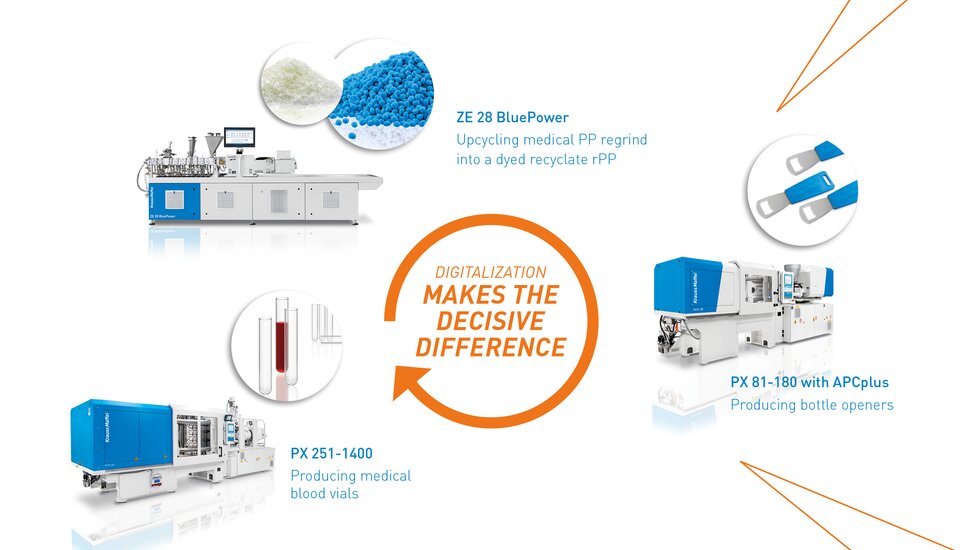

Complete material cycle from medical blood vials to bottle openers

"Make plastic green - with high quality and efficiency." Is KraussMaffei's motto at the NPE in Orlando, Florida (May 6 to 10). The focus of the trade fair presentation will be on future-oriented technologies and solutions with a focus on circular economy and reducing the CO2 footprint.

Visitors to the KraussMaffei booth will be able to experience the entire material cycle from a medical blood vial to a bottle opener.

Starting with injection molding on a PX 251-1400, through the upcycling process using the ZE 28 BluePower twin-screw extruder, to injection molding on a PX 81-180, KraussMaffei will be demonstrating the valuable recycling of raw materials from disposable items through to the production of stylish components with a long service life.

The all-electric PX 251-1400 produces 32 blood vials per shot with an ExxonMobil PP 9074 MED. These disposable items - shredded - serve as the basis for the upcycling process using the ZE 28 BluePower twin-screw extruder.

Here, various additives such as adhesion promoters and liquid color are added, mixed and homogenized. The resulting recompound is then sent to the next injection molding machine - the all-electric PX 81-180.

Every part a good part with APCplus

As recyclates often have different viscosities and can therefore cause process fluctuations, the PX 81-180 is equipped with APCplus. This machine function reliably compensates for these fluctuations.

This allows components to be produced with consistently high quality and waste to be reduced to a minimum - another important contribution to greater sustainability.

KraussMaffei at NPE

West Hall A, Stand W600

Contact

franz-xaver.keilbach@kraussmaffei.com