sustainability

From passenger to cargo aircraft

| Petra Rehmet

Renowned NIAR Institute relies on FiberForm technology from KraussMaffei

It's two worlds coming together - and stimulating each other: The US-American NIAR institute is renowned for investigating how modern composite technologies can be safely and efficiently used in aviation, for example when converting passenger aircraft into cargo planes. KraussMaffei is supporting with their vast knowledge gained from the efficiency-driven automotive industry. On a KraussMaffei GX 450 equipped with the FiberForm technology, aircraft window plugs are produced to demonstrate ultra-high-rate manufacturing.

There is even a separate word for this: preighter. Created during the coronavirus crisis, when hardly any people were traveling, it refers to a passenger jet used (temporarily) as a cargo plane. And the permanent solution is also common: aged airships that no longer offer the latest comforts still cut a good figure as cargo aircraft. Demand is high, as the purchase price is only a fraction of that of new aircraft.

Composites are a convincing economic alternative to metal

Amongst many other tasks, passenger to cargo conversions require replacing acrylic window plugs with metallic alternatives for ease of maintenance. This costly and time-consuming metallic solution can be further optimized by modern fiber-reinforced thermoplastic composites that offer the same stability at lower costs, less weight, and in a fraction of the time it would take to machine the metallic solution.

Passenger aircraft at NIAR ready for conversion to cargo aircraft.

The National Institute for Aviation (NIAR) at Wichita State University (Kansas, USA) and its Advanced Technologies Lab for Aerospace Systems (ATLAS) are investigating issues such as these, and at the same time, training the specialists of tomorrow. A total of around 1,600 employees are active at six NIAR locations, with the total annual volume of R&D projects amounting to more than 300 million dollars. With the KraussMaffei partnership, NIAR has gained active support with industry expertise on plastic molding.

We have had a real partnership for two years. KraussMaffei has not only set up a machine with multiple capabilities, but has also been actively helping us on-site with process development. Our students also gain a tremendous amount of hands-on experience and get to interact with the supply chain for several new capabilities we introduced in recent years. Our goal is to transfer the efficient processes such as FiberForm from automotive production to aviation.Dr. Waruna Seneviratne

Director NIAR ATLAS

Pushing together the introduction of thermoplastic lightweight construction in aviation:

Nolan Strall (President Krauss-Maffei Corporation), Dr Waruna Seneviratne (Director of NIAR ATLAS) and Eugen Schubert (Sales and Application Manager Krauss-Maffei Corporation) (from left to right)

FiberForm saves valuable cycle time

With FiberForm, a fully consolidated fiber-reinforced thermoplastic sheet known as organosheet is inserted into the tool, formed and overmolded with a thermoplastic polymer. In the case of the window plugs, this is done on a GXW 450-2000/1400 with a swivel platen. In an extensive project sponsored by the US Air Force for developing affordable and sustainable manufacturing technologies for aerospace applications, Dr. Waruna Seneviratne’s team is working with Eugen Schubert, Sales and Application Manager KraussMaffei.

Together they are developing the manufacturing process supported by process simulations to ensure the part performance meet the technical requirements. Numerous simulations conducted at NIAR were instrumental in part and tool design. The process simulations carried out were verified through inspections at various stages of the process so that these tools can be used for future developments.

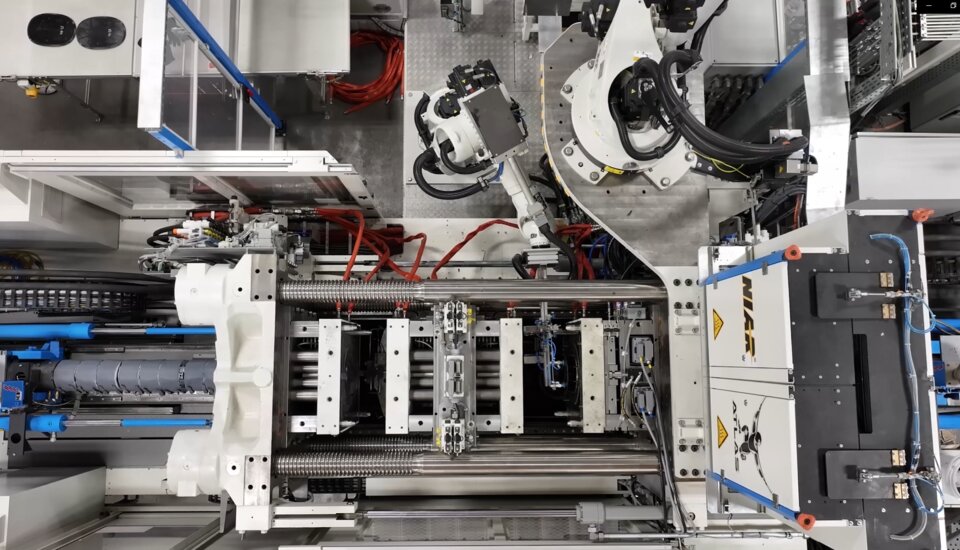

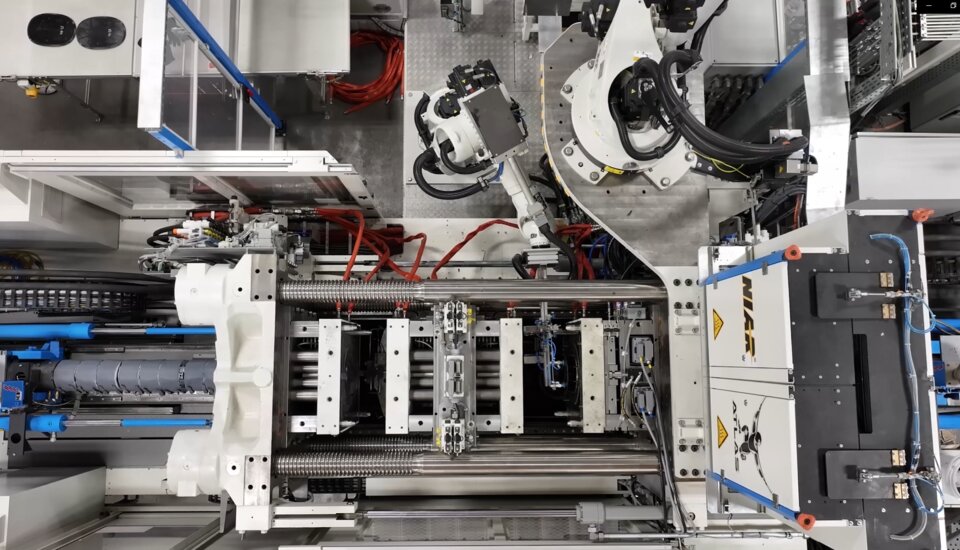

Thermoplastic lightweight construction for large-scale production:

NIAR ATLAS is researching the possibilities of the FiberForm process for aviation on a GXW 450-2000/1400 with swivel platen unit from KraussMaffei.

The window plug was designed with the oval-shaped geometry of the original airplane window with appropriate design modifications, ex., adding ribs to stiffen it to withstand pressure loads. In order to achieve the desired mechanical properties, the team used high-performance plastics LM-PAEK reinforced with AS4 carbon fibers for the 16-ply organosheet and 30% chopped-fiber-filled PEEK for overmolding the ribs.

Due to the higher melting temperature of the PEEK, the two materials fused together optimally when the flow front meets the organosheet.

Fully automated process

Different variants were tested for fully automated production, and the following sequence emerged: First, the flat organosheet is heated in an infrared (IR) oven, inserted into the first station of the mold, formed and pressed, the mold opens, the turning unit rotates and transports the blank to the second cavity for overmolding, while the next organosheet is inserted at the front, getting it ready for thermoforming.

A look inside the mold:

The so-called organosheet, thermoplastically impregnated continuous fibers, is inserted into the mold, formed and overmolded.

The cycle time is so short that 40 window closures can be produced within an hour. This is one of the major advantages of fast injection molding compared to metal machining and also compared to reaction processes.

Excellent cycle times:

Thanks to the fast cycle times in injection molding, up to 40 composite window plugs are produced in one hour using the FiberForm process

The thermoplastics used for FiberForm offer the possibility of welding components, have a high impact strength, are resistant to high temperatures, chemical and environmental influences and are also flame-retardant.

Compared to its metal counterpart (590 grams), the composite overmolded version of the window plug weighs 20 percent less. The team is already working on further optimizing the structure to make it about 40 percent lighter than the metallic counterpart.

Significantly lighter and more cost-efficient to process than metal:

The thermoplastic window plates produced with FiberForm.

Seamless tracking with the dataXplorer

In safety-relevant applications such as aviation, particular attention is paid to the traceability of production processes. With the dataXplorer, KraussMaffei offers a perfect solution here. Over 500 signals can be recorded and stored every 20 milliseconds.

The dataXplorer allows the entire process to be viewed as if under a microscope. We have used the dataXplorer extensively for the development of the window panels and have repeatedly incorporated the knowledge gained into process changes.Eugen Schubert

Sales and Application Manager Krauss-Maffei Corporation

The next step for the NIAR program is to subject the window plugs to further functional tests required for certification – for example with regard to durability – so that it is ready for series production. It is a win-win scenario for everyone involved: NIAR can successfully implement automotive manufacturing technologies into the aviation industry, and KraussMaffei strengthens its commitment in support the needs of the aviation sector.

Joint appearance at the NPE

But first, Nolan Strall (President of KraussMaffei Corporation North America) is looking forward to a joint appearance at the trade show (May 6-10, 24, Orlando/Florida): "The NPE is the showcase for the plastics industry in North America and we will be welcoming customers to our booth with our partners from NIAR. The combined expertise will certainly be attractive to many trade fair visitors." More projects are therefore likely to follow the window plug project.

First place in SAMPE Technical Paper Awards

The project has already received its first award. The accompanying technical paper "Ultra-High-Rate Manufacturing of Thermoplastic Window Plug Using Hybrid Overmolding" by Dr. Waruna Seneviratne and Eugen Schubert won first place in the SAMPE 2024 Technical Paper Awards. The winners will be honored at the SAMPE Awards Breakfast on May 23, 2024.

Contact

eugen.schubert@kraussmaffei.com