sustainability

MuCell in sight

| Petra Rehmet

Live @Fakuma: Foamed component with IML decoration and new screw

These are currently pressing questions of our time: How can we noticeably reduce the use of material and energy in the production of plastic components, thereby reducing CO2 emissions and protecting the environment? At Fakuma (Booth A7-7303) KraussMaffei and its partners demonstrate how physical foaming can provide answers to these questions. The new MuCell universal screw enables a quantum leap with 30 percent more plasticizing performance - as does APCplus, which for the first time also ensures shot weight consistency with MuCell.

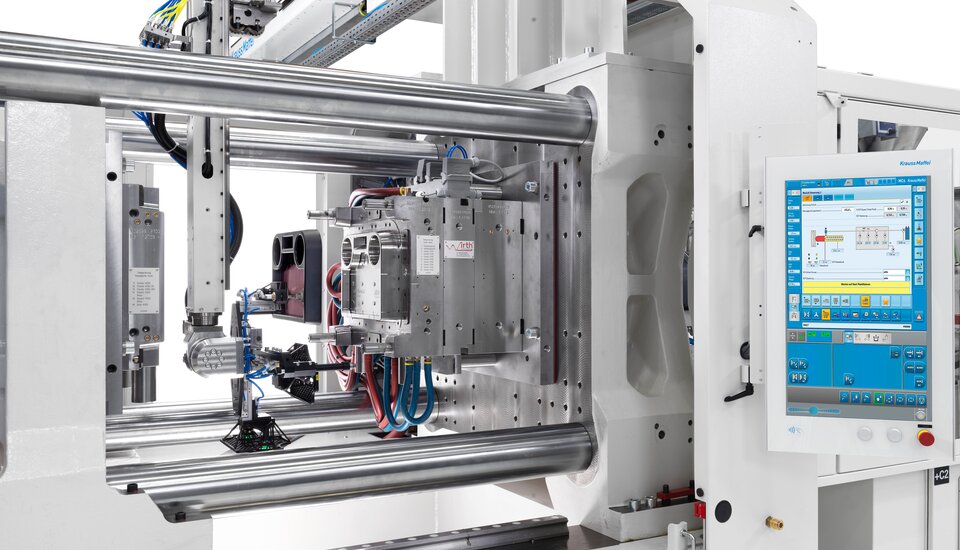

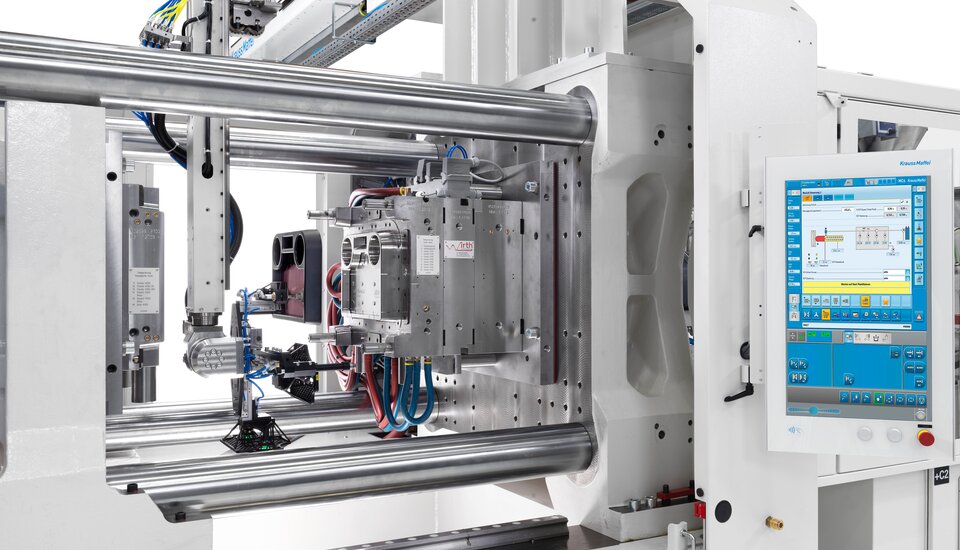

A visible part with a grained surface, perforations, foil decoration: KraussMaffei is addressing several hot topics at Fakuma and making it clear that MuCell is definitely suitable for applications that you might not have thought of. The demo product, a deposit table for semi-trucks and commercial vehicles, emerges on an all-electric PX 321-1400 with high-performance automation – and a new screw.

30 percent higher plasticizing capacity

MuCell refers to the physical foaming of plastics through the addition of a blowing agent, usually nitrogen. This saves material and also improves the flow properties of the melt. In extensive development work, the KraussMaffei team examined all screw designs available on the market and was able to test variants of the front and middle nonreturn valves as well as single-flight and double-flight three-zone zones using a modular system.

This resulted in the new HPS-Physical Foaming universal screw, which is suitable for a wide variety of raw materials (with and without fiber reinforcement) and offers up to a 30 percent increase in plasticizing capacity. An extended three-zone area makes the melt even more homogeneous until it reaches the center nonreturn valve and the gas supply area. This allows for the selection of lesser screw diameters than before, which significantly reduces investment and operating costs for the plasticizing unit, or for the generation of a greater output using a screw of the same size as before.

Live @Fakuma: The PX 321-1400 MuCell with the new univeral screw

APCplus in use for the first time with MuCell

Further development work was also performed on the APCplus machine function, which is now being used with gas-laden melt for the first time. As is the case with compact injection molding, APCplus shifts the changeover point and the holding pressure profile from shot to shot based on the measured melt viscosity.

Although MuCell largely eliminates holding pressure due to foaming, there is still a changeover point and the very brief approach of a holding pressure profile stage to slow down the screw. This is where APCplus comes in and shifts this changeover point and the holding pressure profile in each case based on the melt viscosity determined, which results in extremely weight-constant components.

Every part a good part: With the machine function APCplus

Extensive partner network of specialists

In the trade show application itself, the technical extras begin with surface decoration via in-mold labeling. When using conventional films, bubbles could form due to the outgassing nitrogen, but project partner Isosport (Eisenstadt, Austria) has supplied a suitable design.

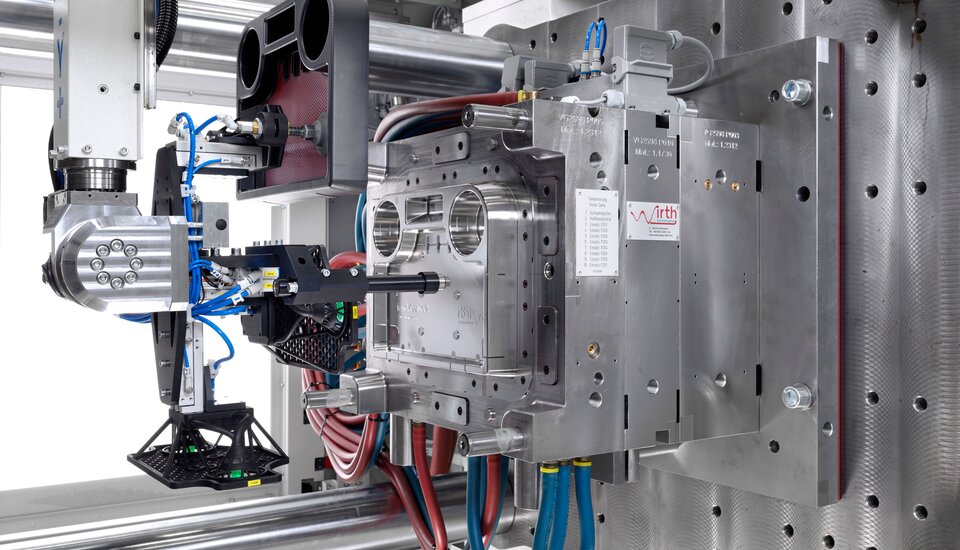

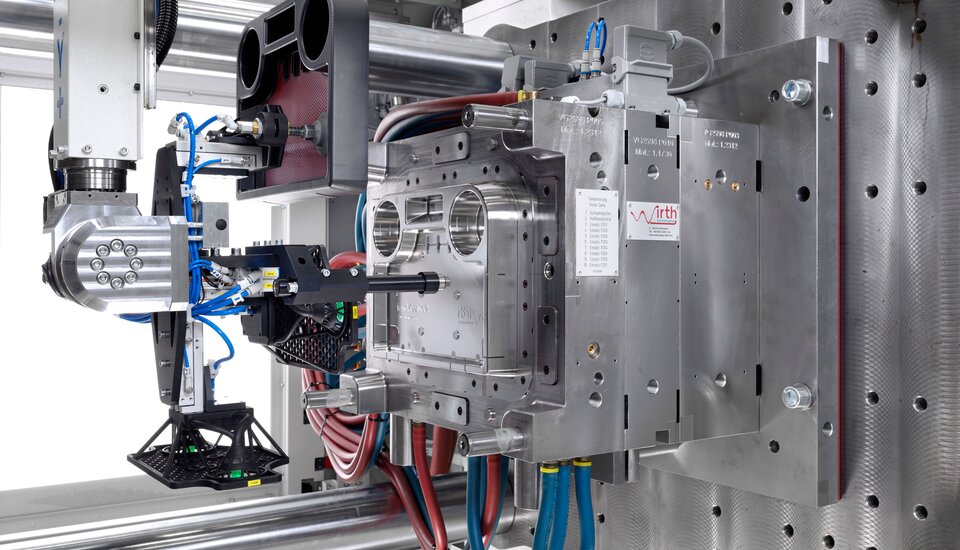

KraussMaffei also brought a specialist on board for the mold: Werkzeugbau Wirth (Helmbrechts), who demonstrated their skills using the opening stroke. In the vast majority of MuCell applications, the cavity is relined, i.e. only about 90 percent filled, in order to leave enough space for the foam to form. The more elegant option, and one with which the highest possible degree of foaming can be achieved, is to fill it completely so that no expansion occurs initially, and then to raise the mold slightly.

Thus, the same pressure level prevails everywhere initially, which is advantageous for visible surfaces. However, this usually requires immersion edges - which makes the mold more complex. Wirth, on the other hand, has some experience in dispensing with immersion edges and also provided proof that this works for the trade show project.

Perfect surfaces, even in critical areas

For molds for MuCell, precise cooling is particularly important to prevent what is known as the post-blow effect. This effect makes bubbles emerge on the surfaces after the process—while the melt in the interior of the component is still hot—and renders the part unusable. In the trade show application, special mold cooling channels ensure uniform cooling at the surface—without variothermal technology—and safely prevent hot spots.

In combination with the graining of the company Reichle (Bissingen/Teck), perfect surfaces are created even in critical areas such as the openings in the tray table (for coin holders) and the binding seams that are formed. Another prerequisite for the streak-free surface aesthetics is a suitable material. Partner Lyondellbasell has a wealth of experience with polyolefins in the visible area of foamed components and already supplies them to OEMs.

With immaculate surfaces: At Fakuma, the PX 321-1400 produces a storage table for trucks in four different designs

Precise temperature control in the mold

In addition to the cooling in the mold, an efficient machine-side temperature control system is necessary. It is provided by Jurke Engineering. Orca measures the speed and quantity of the flow by ultrasonic means — from the outside and without contact with the medium. Precise temperature control allows the cycle time to be optimized.

KraussMaffei has been working successfully with Trexel, the first supplier of MuCell, since 2001. The metering system is provided by this reliable partner. It is fully integrated into the KM MC6 control system and consequently ensures very easy, intuitive handling. If necessary, even satellite solutions are offered by both partners that allow multiple machines, all fully integrated, to be supplied with the necessary gas using only one compressor.

Sophisticated automation

The automation for manufacturing the deposit table comes directly from KraussMaffei. An LRX 150 linear robot picks up the blank film from a drawer in which four different film types can be kept close at hand. Then the robot puts down the selected film on the cleaning station, where all particles and/or contaminants are removed using a cleaning brush from Wandres (Stegen, Germany) and the matching extractor system from ESTA (Senden, Germany), two more of our partners. The robot gripper executes a turn concurrently with the cleaning process so that clean suction devices pick up the film again.

A look inside the mold: The LRX 150 linear robot removes the finished part

Then the "stack gripper" inserts the film into the mold, and the finished part is demolded. Demolding is followed by the handshake transfer to a second robot for a foam structure test of the component by means of a testing system from Teratonics (Orsay, France). The testing system specifically allows users to visualize the compact outer layers and the spatial distribution of the MuCell foam in the interior of the component and to assess the production as free of bubbles. After this test has been completed, the component is placed on a conveyor belt and transported out of the automated system.

All the data at a glance with easyTrace

The easyTrace 2.0 systems collects all data related to the injection process and the structural test shot by shot and displays it on a screen. In addition, a QR code appears under which all process parameters for this individualized component have been stored. Here, easyTrace 2.0 acts as an interface system that gathers all data of all process nodes and functions as an interpreter for existing customer-side MES or ERP systems.

MuCell provides a wide variety of options to reduce the CO2 footprint through material and energy savings. The trade show application demonstrates that it succeeds in doing so even in the production of challenging visible parts.

Contact

andreas.handschke@kraussmaffei.com