trendgineering

Unparalleled productivity and cost-effectiveness

| Andreas Weseler

Production of tire components with the Quintoplex extrusion head

Dr. Gerard Nijman, Global Product Manager Tire & Rubber at KraussMaffei, has more than 30 years of experience in the field of tire production and is a recognized expert of production processes in this branch of industry. In today's interview, he talks about the KraussMaffei Quintoplex extrusion head for tire components and explains the advantages offered by this solution.

Dr. Gerard Nijman, Global Product Manager Tire & Rubber at KraussMaffei.

Ahead:

Could you please give us a brief introduction to the Quintoplex head?

Dr. Gerard Nijman:

Yes, with pleasure. The Quintoplex head is the recognized benchmark in terms of quality, line speed, retooling times for product changes and material savings. With over 50 Quintoplex heads sold around the globe, it has gained a strong foothold in the industry since its market launch. This head is equally designed for tire manufacturers with frequent or less frequent dimension or compound changes. The Quintoplex head offers users short set-up times and thus unparalleled productivity and cost-effectiveness.

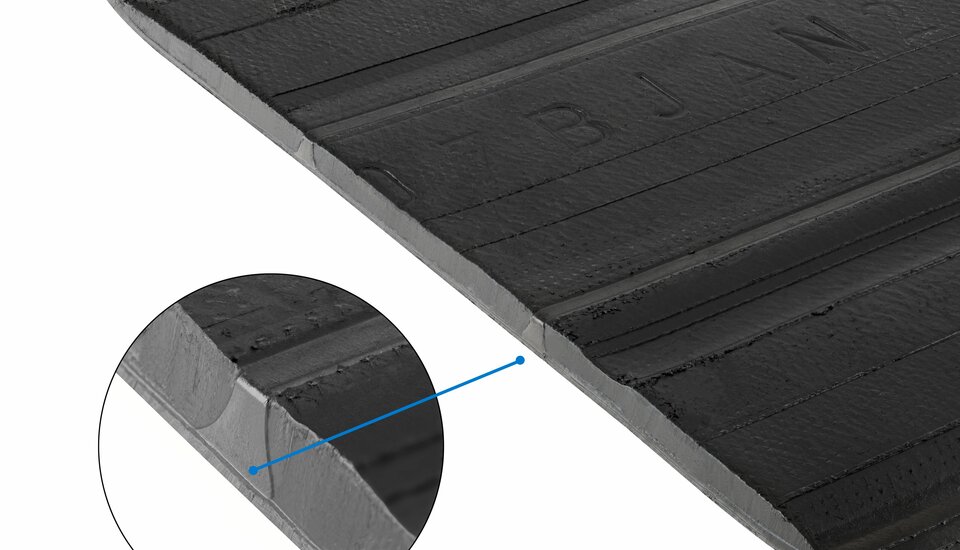

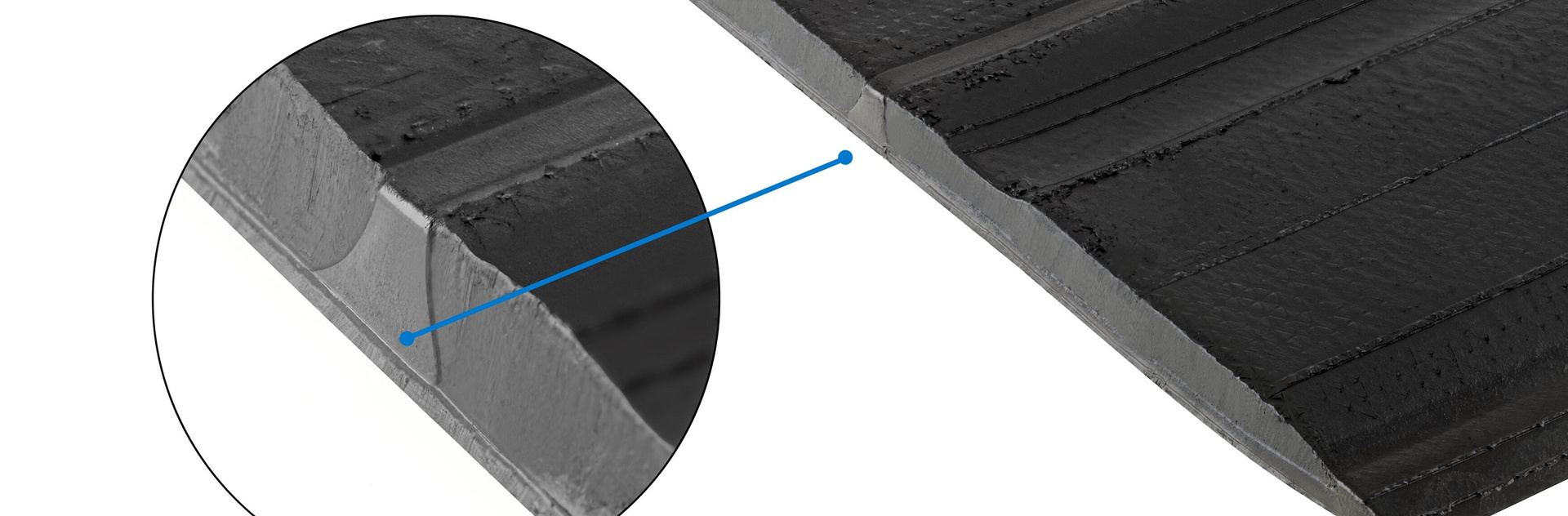

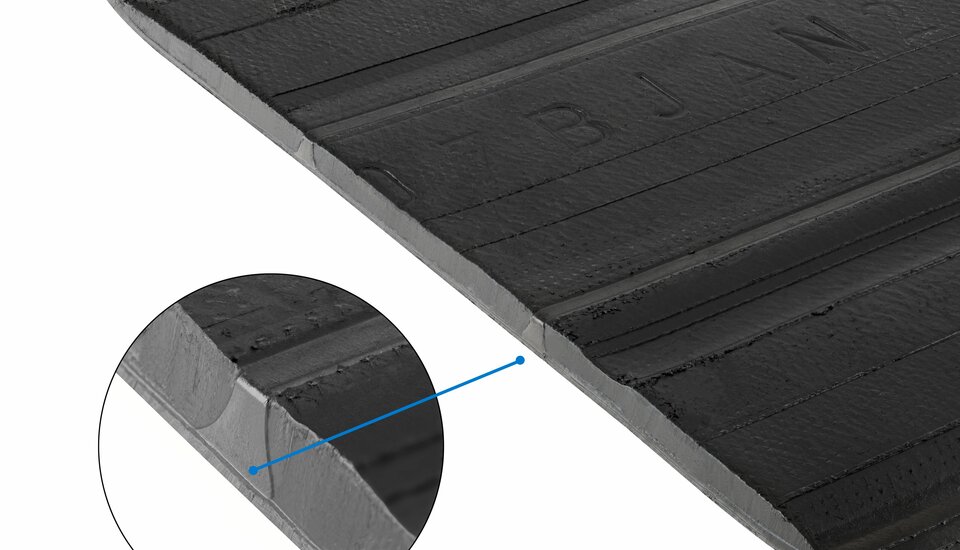

The Quintoplex extrusion head reduces set-up times in the event of compound changes and the scrap produced when the extruder is emptied.

Ahead

What are the special features of the new closing mechanism?

Dr.Gerard Nijman

It improves access to the flow channels and saves cleaning time. The upper and lower head parts can be separately opened in order to reduce set-up times in the event of compound changes and the scrap produced when the extruder is emptied. The head equipped with the proven locking system provides excellent tightness at extrusion pressures of up to 250 bar. The optimum arrangement of the closing and locking devices prevents any deformation of the extrusion tool and thus ensures maximum dimensional accuracy of the extruded product. In addition, the Quintoplex head design allows the rubber compound in a single extruder to be changed without having to clean the complete extrusion head.

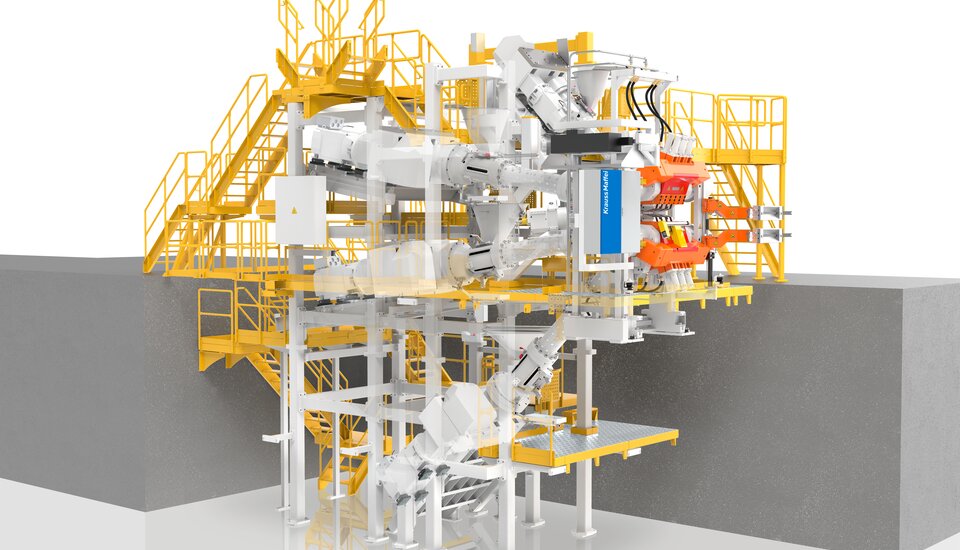

Quintoplex extrusion line with five different extruders.

Ahead:

How are KraussMaffei extrusion lines configured for the tire industry?

Dr. Gerard Nijman:

KraussMaffei extrusion lines are designed for premium product quality and maximum output rates and can be equipped with different extruder design variants (GE-SC or GE-W, GE-KS) and sizes. Thanks to the modular design, the line configuration can be easily tailored to the desired profile cross sections. Using the Quintoplex flagship configuration, different tire components like two caps, base, wings, cushion etc. can be produced in a single process by six or seven extruders depending on the customer specification. As up to two small extruders can be integrated directly into the head, even a conductive chimney and/or a colored wear indicator in the tread can be simultaneously added.

We would like to thank Dr. Nijman for taking the time for this interesting and informative interview.

Tread composed of five different components with a conductive chimney.